Description

Our Stainless Steel Cyclone Separator delivers efficient liquid-solid separation, reducing maintenance costs and enhancing system reliability for industrial filtration needs.

Industries – Cut Costs with Durable Separation

304 Stainless Steel Construction

Enhances corrosion resistance, extending product lifespan in harsh conditions.

High Separation Efficiency

Removes up to 98% of particles above 50 microns, ensuring cleaner liquid output.

Maintenance-Free Operation

Eliminates the need for filter media replacement, reducing operational costs.

Compact Design

Easy integration into existing pipelines, saving space and installation time.

Features

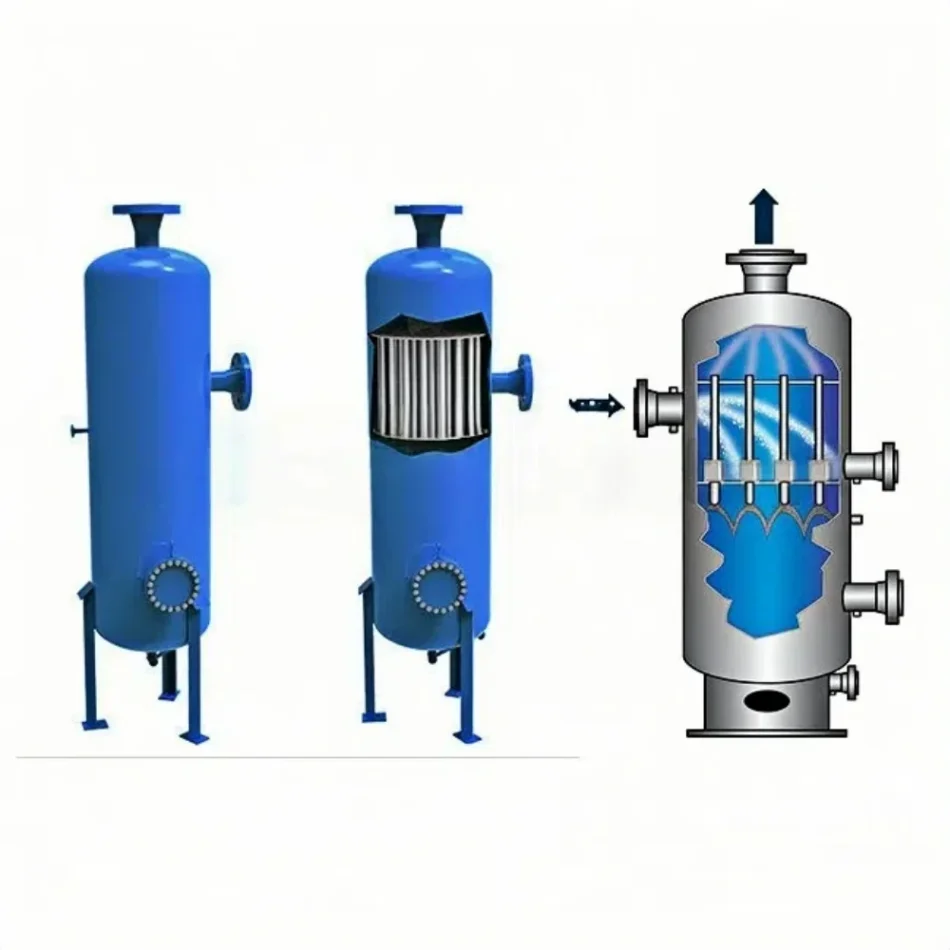

The Stainless Steel Cyclone Separator features a conical body design that introduces liquid tangentially, creating a powerful vortex. This vortex forces heavier particles to the outer wall and downward into the collection chamber, while clean liquid exits through the top. The separator is constructed from 304 stainless steel, ensuring durability and resistance to corrosion. It comes with a customizable voltage option and a 1-year warranty.

Benefits

By using our Stainless Steel Cyclone Separator, customers benefit from reduced maintenance costs due to its maintenance-free operation. The high separation efficiency ensures cleaner liquid output, protecting downstream equipment from blockage and wear. Its compact design allows for easy integration into existing systems, saving space and installation time. The corrosion-resistant materials make it suitable for harsh industrial environments, extending its lifespan.

Use Cases

The Stainless Steel Cyclone Separator is ideal for a wide range of industrial applications, including cooling water systems, agricultural irrigation, industrial process water treatment, oil & slurry separation, municipal & wastewater pre-treatment, and filtration of rainwater or groundwater. In cooling water systems, it removes rust, scale, and particulate matter, protecting pumps and heat exchangers. For agricultural irrigation, it filters out sand and organic matter, preventing clogging in drip irrigation systems. In industrial processes, it pre-filters process liquids, reducing filter cartridge load. It also separates sand and sludge from drilling fluids in the petrochemical industry, improving oil recovery efficiency.

|

item

|

value

|

|

Material

|

Stainless Steel

|

|

Max. Capacity

|

500LPH

|

|

condition

|

New

|

|

place of origin

|

Shanghai,China

|

|

brand name

|

SFFILTECH

|

|

voltage

|

Customized

|

|

power(w)

|

|

|

dimension(l*w*h)

|

|

|

weight

|

50

|

|

warranty

|

1 Year

|

|

Special Feature

|

easy installation

|

|

Dimensions

|

|

|

Container type

|

Bottle

|

|

Product name

|

Cyclone Separator

|

|

Handle traffic

|

5-50m³/h

|

|

Separator height

|

600-1500mm

|

|

Barrel diameter

|

90-300mm

|

|

Interface size

|

DN25 DN40 DN50 DN80 DN100

|

|

packet

|

customed

|

Why Choose Our Stainless Steel Cyclone Separator?

Our separator offers high separation efficiency, maintenance-free operation, and durable construction, making it ideal for various industrial applications.

How Does It Work?

The separator uses centrifugal force to separate solid particles from liquids, ensuring cleaner output and protecting downstream equipment.

What Are the Key Benefits?

Key benefits include reduced maintenance costs, extended product lifespan, and easy integration into existing systems.