Smart Guide: Choosing Dust Collector Filter Bags

Navigating the maze of industrial filtration? You’re not alone. Every industrial scene, from chemical plants to food processing units, demands tailored dust collector filter bags. But how do you pinpoint the perfect match? Dive in as we unravel the secrets to selecting dust collector filter bags that elevate your filtration game, ensuring cleaner air and smoother operations.

Industrial Scene Analysis: Dust Characteristics & Filtration Needs for Dust Collector Filter Bags

When it comes to selecting the right dust collector filter bags for your industrial operations, understanding the unique粉尘 characteristics (let’s call them ‘dust personalities’ for fun) and filtration needs of each scene is crucial. After all, not all dust is created equal! Let’s dive into some of the most common industrial settings—chemical, food processing, and metal smelting—to uncover what makes their dust so distinct and how it impacts your filter bag choice.

Chemical Industry: The Corrosive Challenge

In the chemical industry, dust isn’t just dust; it’s often a cocktail of corrosive particles that can wreak havoc on unsuspecting filter materials. Imagine dealing with acidic fumes or alkaline powders that can eat through weaker fabrics like a hot knife through butter. Here, you need filter bags made from materials that can stand up to the chemical onslaught. Think polyester, PTFE (Polytetrafluoroethylene), or even specialized aramid fibers that offer excellent chemical resistance. These materials ensure your filter bags last longer and perform consistently, even in the harshest environments.

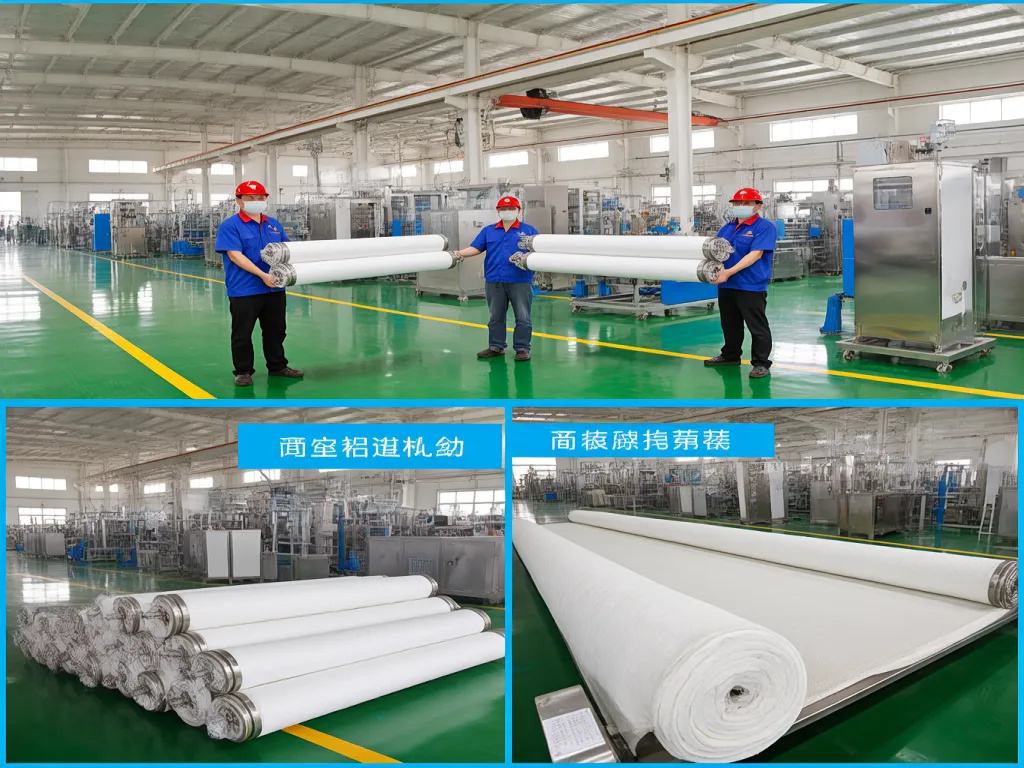

Food Processing: The Hygiene Imperative

Now, let’s switch gears to the food processing industry, where cleanliness is next to godliness—or at least, next to regulatory compliance! Here, dust isn’t just a nuisance; it’s a potential health hazard. Food particles, spices, and even microscopic bacteria can linger in the air, posing a risk to product quality and consumer safety. For this scene, you’ll want filter bags that are not only efficient at capturing fine particles but also easy to clean and sanitize. Materials like polypropylene or food-grade polyester are popular choices, offering a balance between filtration performance and hygiene compliance. Plus, they’re often treated with anti-static properties to prevent dust buildup and reduce fire risks—a win-win!

Metal Smelting: The Heat Is On

Finally, let’s tackle the metal smelting industry, where temperatures soar and dust particles can be as abrasive as they are hot. In this fiery environment, your filter bags need to withstand extreme heat without melting or degrading. Enter fiberglass and Nomex filter bags, the superheroes of high-temperature filtration. Fiberglass bags can handle temperatures up to 500°F (260°C), while Nomex, a heat-resistant aramid fiber, can go even higher, up to 400°F (204°C) continuously. For a deeper understanding of how temperature affects filter bag performance, you may refer to this technical guide on high-temperature filtration materials. These materials ensure your filter bags stay intact and effective, even when the smelting furnace is roaring.

Why Material Matters So Much

You might be wondering, ‘Why does the material of my dust collector filter bags matter so much?’ Well, think of it like choosing the right outfit for a job interview. You wouldn’t wear a swimsuit to a corporate meeting, right? Similarly, selecting the wrong filter material for your industrial scene can lead to poor performance, increased maintenance costs, and even safety hazards. By understanding the dust characteristics and filtration needs of your specific industry, you can make an informed decision that ensures optimal performance and longevity for your filter bags.

Beyond the Basics: Custom Solutions

While we’ve covered some of the most common industrial scenes, it’s important to remember that every operation is unique. You might have specific requirements or challenges that don’t fit neatly into one category. That’s where custom solutions come in. Many filter bag manufacturers offer tailored options, combining different materials or adding special coatings to meet your exact needs. Don’t be afraid to ask for a customized solution—it could be the key to unlocking unparalleled filtration performance in your industrial setting.

Performance Metrics Unveiled: How Filter Bags Excel in Diverse Industrial Settings

When it comes to selecting the right dust collector filter bags for your industrial operation, understanding the core performance metrics—filtration efficiency, dust holding capacity, and air permeability—is absolutely crucial. These metrics aren’t just numbers on a spec sheet; they directly impact how well your filter bags perform in real-world scenarios. Let’s dive deeper into each one and see how they shape the effectiveness of filter bags across different industries.

Filtration Efficiency: The Heart of Clean Air

Filtration efficiency measures how effectively a filter bag captures and retains dust particles. It’s usually expressed as a percentage, indicating the proportion of particles of a specific size that the filter can remove from the air stream. In industries like food processing, where even tiny particles can contaminate products, high filtration efficiency is non-negotiable. Imagine a bakery where flour dust needs to be kept at bay to ensure product quality and worker safety. A filter bag with 99.9% efficiency would be ideal here, capturing nearly all airborne particles and maintaining a clean working environment.

On the other hand, in less sensitive environments like metalworking, where the primary concern might be reducing visible dust emissions rather than achieving absolute cleanliness, a slightly lower efficiency might suffice. But remember, lower efficiency can mean more frequent filter changes and higher long-term costs. So, it’s a balancing act between initial investment and ongoing maintenance.

Dust Holding Capacity: The Unsung Hero of Longevity

Dust holding capacity, or simply ‘capacity’, refers to the amount of dust a filter bag can accumulate before it needs to be cleaned or replaced. This metric is particularly important in industries with high dust loads, such as cement production or woodworking. A filter bag with a high capacity can operate longer between cleanings, reducing downtime and maintenance costs.

Think about a cement plant where dust generation is constant and heavy. A filter bag with a low capacity would quickly become clogged, leading to increased pressure drops across the filter and reduced airflow. This not only affects the efficiency of the dust collection system but can also lead to premature filter failure. Conversely, a high-capacity filter bag can handle the dust load more effectively, maintaining optimal performance over a longer period.

Air Permeability: The Breath of Fresh Air

Air permeability, often referred to as ‘breathability’, measures how easily air can pass through the filter bag. It’s a critical factor in determining the pressure drop across the filter and, consequently, the energy consumption of the dust collection system. In industries where airflow is key, such as pharmaceuticals or electronics manufacturing, high air permeability is essential to maintain process efficiency and product quality.

Imagine a pharmaceutical plant where cleanrooms need to maintain strict air quality standards. A filter bag with low air permeability would restrict airflow, making it harder to achieve the required ventilation rates. This could lead to increased energy consumption as fans work harder to push air through the clogged filter, not to mention the potential for reduced product yields due to poor air quality. On the flip side, a filter bag with high air permeability ensures smooth airflow, minimizing pressure drops and energy costs while maintaining a clean environment.

Chemical Industry: Balancing Efficiency and Durability

In the chemical industry, where corrosive gases and fine particulates are common, filter bags must strike a delicate balance between filtration efficiency and durability. The choice of materials here is paramount. For instance, PTFE (Polytetrafluoroethylene) membranes offer exceptional chemical resistance and high filtration efficiency, making them ideal for capturing acidic or alkaline dusts. However, their cost can be higher compared to other materials. For a deeper understanding of how material selection impacts filter bag performance, you can explore this chemical resistance guide. So, it’s about weighing the benefits against the budget to find the sweet spot.

Food Processing: Purity and Hygiene First

When it comes to food processing, the stakes are high. Contamination can lead to product recalls, health risks, and damaged brand reputation. Therefore, filter bags in this sector must prioritize purity and hygiene. Materials like polyester felt with antistatic properties are popular choices, as they prevent dust buildup and reduce the risk of fires. Additionally, food-grade certifications ensure that the filter bags meet strict hygiene standards, giving you peace of mind.

Metalworking: Handling Heavy Dust Loads

Metalworking shops generate a significant amount of coarse and abrasive dust. Here, filter bags need to have robust construction and high dust holding capacity to withstand the rigors of daily use. Nomex or aramid fibers are often used for their heat resistance and durability. These materials can handle the high temperatures generated during welding or cutting processes without degrading quickly. Moreover, their ability to capture large particles efficiently reduces the frequency of filter changes, saving time and money.

Real-World Success Stories: Choosing and Applying Dust Collector Filter Bags

When it comes to industrial filtration, the right choice of dust collector filter bags can make or break your system’s efficiency. Let’s dive into some real-world scenarios where businesses have successfully navigated the complexities of selecting and applying these crucial components, learning valuable lessons along the way. Imagine a bustling chemical plant, where the air is thick with a mix of corrosive gases and fine particulates. Here, the choice of filter bag material is paramount. We worked closely with a client facing severe filter bag degradation due to chemical exposure. Initially, they opted for a standard polyester bag, which quickly succumbed to the harsh environment. After a thorough analysis, we recommended switching to a PTFE-coated fiberglass bag. This upgrade not only extended the bag’s lifespan significantly but also improved filtration efficiency, reducing downtime and maintenance costs. The lesson? Always consider the chemical resistance of the filter bag material in corrosive environments. Now, let’s shift gears to the food processing industry, where hygiene and product purity are non-negotiable. A bakery client of ours struggled with frequent filter bag clogging, leading to inconsistent airflow and compromised product quality. Their initial choice of a generic filter bag lacked the necessary anti-static properties, causing fine flour particles to cling to the bag surface. By switching to a food-grade, anti-static polyester bag, we observed a dramatic improvement. The new bags prevented particle buildup, ensuring consistent airflow and maintaining the bakery’s high standards of cleanliness. This case highlights the importance of selecting filter bags tailored to the specific needs of the food processing sector, where even minor contaminants can have major repercussions. Moving on to metal metal smelting, a sector known for its high-temperature operations and abrasive dust. A steel manufacturing client faced premature filter bag failure due to extreme heat and mechanical wear. Their initial choice of a standard needle-felt bag couldn’t withstand the rigors of the smelting process. After consulting with our experts, they adopted a high-temperature, aramid-based filter bag. These bags demonstrated exceptional heat resistance and durability, withstanding temperatures up to 250°C without compromising filtration performance. The takeaway? In high-temperature environments, opt for filter bags specifically designed to handle extreme heat and mechanical stress. Lastly, let’s not overlook the importance of proper installation and maintenance. A textile mill client of ours experienced frequent filter bag ruptures, attributing it to poor bag quality. However, upon closer inspection, we found that the issue stemmed from improper installation and lack of regular maintenance. By providing comprehensive training on correct installation techniques and establishing a routine maintenance schedule, we helped them achieve a significant reduction in filter bag failures. This example underscores the significance of not just selecting the right filter bags but also ensuring their proper installation and upkeep. In each of these cases, the key to success lay in understanding the unique challenges of the industrial scene and tailoring the filter bag selection accordingly. Whether it’s chemical resistance, anti-static properties, heat tolerance, or proper installation, every detail matters. By sharing these real-world success stories, we hope to empower you to make informed decisions when it comes to choosing and applying dust collector filter bags in your industrial setting.

Chemical Industry Case Study

In the chemical industry, the stakes are high. A misstep in filter bag selection can lead to costly downtime, environmental hazards, and even safety risks. Our client’s experience serves as a cautionary tale, emphasizing the need for materials that can withstand chemical attacks. The switch to PTFE-coated fiberglass bags was a game-changer, proving that investing in the right filter bag material pays off in the long run. For more insights on selecting the right materials for harsh environments, you can refer to this chemical processing guide.

Food Processing Industry Insights

For the food processing industry, cleanliness is king. The bakery’s struggle with clogged filter bags is a common issue faced by many in the sector. The solution lay in recognizing the unique requirements of food-grade environments and selecting filter bags with anti-static properties. This not only improved filtration efficiency but also upheld the highest standards of food safety.

Metal Smelting Sector Solutions

The metal smelting sector demands filter bags that can take a beating. Our steel manufacturing client’s journey from frequent failures to reliable performance highlights the importance of choosing high-temperature, durable materials. Aramid-based filter bags proved to be the perfect fit, demonstrating that the right choice can lead to significant operational improvements.

Installation and Maintenance Matters

Even the best filter bags won’t perform optimally if not installed and maintained correctly. The textile mill’s experience serves as a reminder that proper installation techniques and regular maintenance are crucial for filter bag longevity. By investing in training and establishing a maintenance routine, they were able to minimize failures and maximize efficiency.

Selecting the right dust collector filter bags is pivotal for industrial efficiency and environmental compliance. Throughout this guide, we’ve dissected the nuances of filter bag selection across diverse industrial landscapes. Remember, it’s not just about catching dust; it’s about optimizing performance and sustainability. Armed with these insights, you’re now poised to make informed decisions. Why wait? Explore our range of dust collector filter bags tailored for your industry and take the first step towards a cleaner, more efficient future.