Why Plastic Bag Filter Housings Win Cost-Wise?

In industrial filtration, every penny saved on equipment is a penny earned. For procurement managers and financial analysts, the choice between filter housing materials isn’t just about durability—it’s a strategic cost decision. Enter plastic bag filter housings: often overlooked but packed with hidden economic advantages. From initial purchase to long-term operation, these lightweight champions are rewriting the rules of cost-benefit analysis. But how exactly do they outperform metal counterparts in total lifecycle costs? Let’s dissect the numbers and reveal why smart buyers are making the switch.

Initial Investment Comparison: Plastic Bag Filter Housing vs. Other Materials

When it comes to industrial filtration systems, the initial investment in filter housing can significantly impact your budget. As a purchasing manager or financial analyst, you’re constantly weighing the costs and benefits of different materials. So, how does a plastic bag filter housing stack up against traditional options like metal or stainless steel? Let’s dive into a detailed cost comparison to uncover the economic advantages.

Firstly, let’s address the elephant in the room: upfront costs. Plastic bag filter housings are generally more affordable than their metal counterparts. Why? The manufacturing process for plastics is often less complex and resource-intensive compared to metals, which require mining, refining, and extensive machining. This streamlined production translates to lower prices for you, the end consumer. But don’t just take our word for it; let’s look at some concrete numbers.

Imagine you’re comparing a standard plastic bag filter housing with a similar-sized stainless steel model. The plastic version might cost you anywhere from 30% to 50% less initially. That’s a substantial saving, especially when you’re outfitting an entire facility with multiple units. Now, you might be thinking, ‘But isn’t stainless steel more durable?’ While it’s true that stainless steel has its merits in terms of longevity, the cost difference at the purchase stage is hard to ignore, especially for applications where extreme durability isn’t a make-or-break factor.

But wait, there’s more to the story than just the sticker price. Installation costs also play a role. Plastic filter housings are typically lighter than metal ones, making them easier and cheaper to transport and install. This means fewer man-hours and lower labor costs for your team. Plus, the flexibility of plastic allows for more design variations, potentially fitting into tighter spaces without the need for costly modifications to your existing setup.

Now, let’s talk about maintenance and replacement costs down the line. While this isn’t part of the initial investment, it’s crucial to consider how these factors influence your overall budget. Plastic filter housings are less prone to corrosion compared to metals, especially in harsh chemical environments. This means fewer replacements due to rust or degradation, saving you money in the long run. For more insights on how corrosion affects industrial equipment, you can refer to this detailed guide on corrosion. But more on that in our next section on long-term operating costs.

For now, let’s circle back to the initial investment. Have you ever considered the hidden costs associated with metal filter housings? Things like the need for special coatings to prevent corrosion, or the additional structural support required due to their weight? These aren’t always factored into the initial price tag but can add up quickly. With plastic, many of these concerns are mitigated, offering a cleaner, more straightforward cost proposition.

So, what’s the bottom line? If you’re looking for a cost-effective solution right out of the gate, plastic bag filter housings present a compelling case. They offer significant savings on purchase price, installation, and potential hidden costs associated with metal alternatives. But remember, cost isn’t the only factor to consider. In our upcoming sections, we’ll explore how plastic filter housings fare in terms of long-term operating costs and overall return on investment.

Cost Breakdown: Plastic vs. Metal

To give you a clearer picture, let’s break down the costs. Suppose you’re comparing a 10-inch plastic bag filter housing with a stainless steel equivalent. The plastic model might retail for around $200, while the stainless steel version could set you back $400 or more. That’s a $200 difference per unit. Now, multiply that by the number of units you need for your facility, and the savings become substantial. And this is just the purchase price; we haven’t even factored in installation and maintenance yet.

Installation Ease and Cost Savings

Installation is another area where plastic shines. Due to its lighter weight, a plastic filter housing can often be installed by a smaller crew or even a single technician, depending on the size. This contrasts with metal housings, which might require a forklift or additional manpower to position safely. The result? Lower labor costs and quicker installation times, getting your filtration system up and running faster without breaking the bank.

Long-Term Operating Cost Analysis: Exploring Long-Term Savings of Plastic Materials in Energy Consumption, Maintenance, and Replacement

When it comes to industrial filtration equipment, the long-term operating costs can make or break your budget. That’s why choosing the right filter housing material is crucial. Let’s dive into how plastic bag filter housings shine in terms of energy consumption, maintenance, and replacement costs over time. Have you ever considered how much energy your current filter housing is consuming? Plastic materials, by their nature, are often lighter and more thermally efficient than metal alternatives. This means less energy is required to pump fluids through a plastic housing compared to a heavier metal one. Think about it: every watt saved on energy translates directly into cost savings on your electricity bill. But that’s not all. The thermal conductivity of plastic is significantly lower than that of metals. This translates to less heat transfer during operation, reducing the need for additional cooling systems or energy-intensive temperature control measures. In industries where filtration processes generate substantial heat, this can be a game-changer. Imagine cutting down on both your energy consumption and your cooling costs simultaneously—all thanks to choosing a plastic bag filter housing.

Energy Consumption: The Hidden Cost Saver

You might not realize it, but the material of your filter housing has a direct impact on your energy consumption. Plastic, being lighter and more thermally efficient, requires less energy to operate. This means your pumps don’t have to work as hard, reducing your electricity costs. Plus, the lower thermal conductivity of plastic means less heat is generated during operation, further cutting down on energy needs for cooling.

Maintenance: A Breeze with Plastic

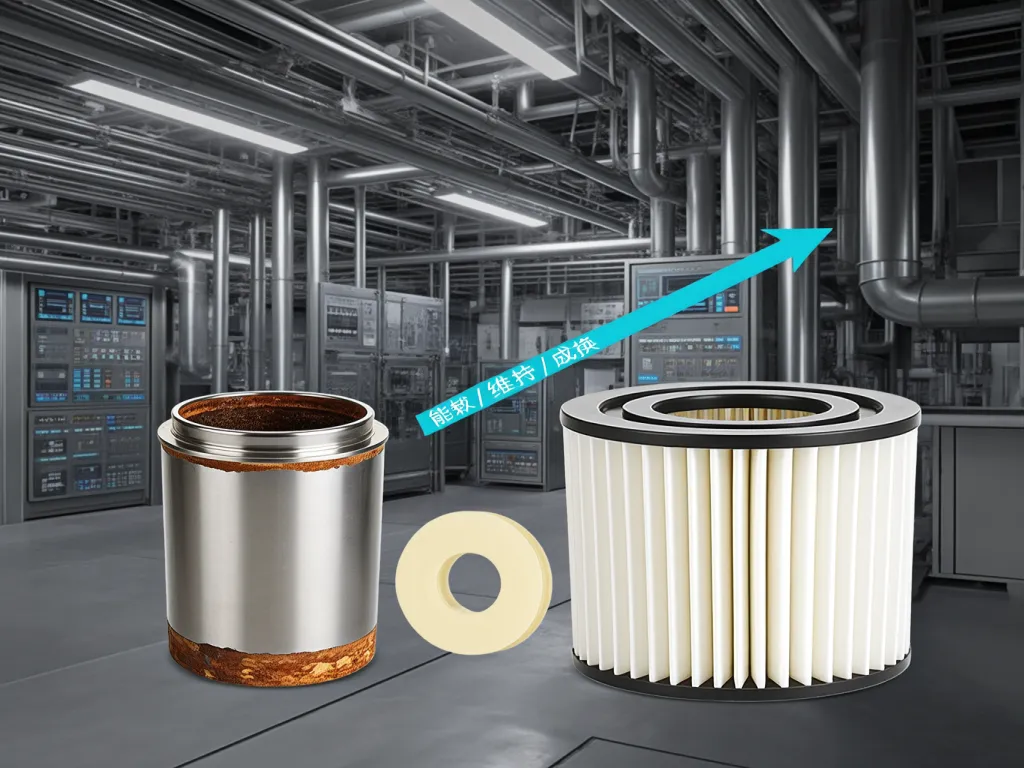

Maintenance is a necessary evil in industrial operations, but it doesn’t have to be a costly one. Plastic bag filter housings are corrosion-resistant, meaning they don’t rust or degrade from chemical exposure like metal does. This translates to fewer inspections, less cleaning, and fewer replacement parts needed over time. The result? Lower maintenance costs and more uptime for your filtration system.

Replacement: Modular Design Equals Cost Savings

When it comes time to replace parts of your filter housing, plastic has a clear advantage. Its modular design allows for easy swapping of affected components, rather than replacing the entire unit. This not only saves on replacement costs but also reduces downtime during maintenance. Compare this to metal housings, where a single point of failure might mean a complete overhaul—a costly and time-consuming process.

Investment Return Calculation: Calculating ROI for Plastic Bag Filter Housings Through Specific Cases

When it comes to industrial filtration equipment, the choice of filter housing material can significantly impact your bottom line. You’ve already seen how plastic bag filter housings shine in initial investment and long-term operating costs compared to metal alternatives. Now, let’s dive into the nitty-gritty of calculating their return on investment (ROI) through real-world examples.

Imagine you’re managing a chemical processing plant that filters 50,000 gallons of liquid per day. Your current metal filter housing system costs $15,000 upfront and requires $3,000 annually in maintenance (cleaning, parts replacement, and potential downtime costs). Its lifespan? About 5 years before needing replacement.

Now, let’s compare this to a plastic bag filter housing system. The initial investment here is $8,000. Maintenance costs drop to $1,200 per year due to plastic’s corrosion resistance and ease of cleaning. Plus, its lifespan extends to 7 years.

Here’s where the ROI magic happens. Over 7 years:

Metal System:

Initial Cost: $15,000

Maintenance (7 years): $21,000 ($3,000 x 7)

Replacement Cost (Year 5): $15,000

Total Cost: $51,000

Plastic System:

Initial Cost: $8,000

Maintenance (7 years): $8,400 ($1,200 x 7)

No replacement needed within 7 years

Total Cost: $16,400

The savings? A staggering $34,600 over 7 years! That’s a 68% reduction in total costs.

But ROI isn’t just about savings; it’s about how much return you get on your investment. The formula is simple: ROI = (Net Profit / Cost of Investment) x 100.

In this case, the ‘Net Profit’ is the savings from choosing plastic ($34,600). The ‘Cost of Investment’ is the initial $8,000 for the plastic system.

ROI = ($34,600 / $8,000) x 100 = 432.5%

Yes, you read that right. A 432.5% ROI over 7 years. That means for every dollar invested in the plastic bag filter housing, you’re getting $4.32 back in savings.

Now, let’s scale this down to a more digestible annual ROI. Divide the total savings by 7 years: $34,600 / 7 ≈ $4,943 per year. Then, divide that by the initial investment: $4,943 / $8,000 ≈ 0.618, or 61.8% annual ROI.

Still skeptical? Let’s consider a smaller-scale operation. A food processing plant filters 10,000 gallons daily. Their metal system costs $10,000 initially with $2,000 annual maintenance and a 5-year lifespan. The plastic alternative? $5,000 initial, $800 annual maintenance, and 7-year lifespan.

Over 7 years:

Metal: $10,000 + ($2,000 x 7) + $10,000 (replacement) = $34,000

Plastic: $5,000 + ($800 x 7) = $10,600

Savings: $23,400

ROI: ($23,400 / $5,000) x 100 = 468%

Annual ROI: ($23,400 / 7) / $5,000 ≈ 66.9%

The numbers don’t lie. Whether you’re a large chemical plant or a mid-sized food processor, plastic bag filter housings deliver exceptional ROI. They’re not just cost-effective; they’re a strategic investment that pays dividends year after year. For those interested in optimizing their filtration systems further, exploring options like wholesale pleated dust filter bags can provide additional cost savings and efficiency improvements.

But here’s the kicker: these calculations don’t even account for potential downtime costs with metal systems. Corrosion, leaks, or parts failures can halt production, costing thousands per hour. Plastic’s durability minimizes these risks, further boosting your ROI.

So, when you’re weighing your options, ask yourself: Can I afford not to choose plastic? The data suggests that sticking with metal could mean leaving significant savings—and competitive advantage—on the table.

In the next section, we’ll wrap up our analysis and issue a clear call to action. But for now, consider this: if you could invest in a technology that quadruples your money over seven years, wouldn’t you jump at the chance? Plastic bag filter housings offer exactly that—a chance to optimize costs, enhance efficiency, and future-proof your filtration operations.

Breaking Down the Numbers

Let’s get granular. The beauty of ROI calculations lies in their ability to reveal hidden costs and long-term benefits. With metal filter housings, you’re not just paying for the initial purchase; you’re buying into a cycle of maintenance, potential downtime, and eventual replacement. Plastic disrupts this cycle by offering a lower initial cost, reduced maintenance, and extended lifespan. The savings compound over time, creating a snowball effect of cost efficiency.

Real-World Impact

These aren’t just theoretical numbers. We’ve worked with clients across industries who’ve made the switch and seen transformative results. One client in the pharmaceutical sector reduced their annual filtration costs by 65% after switching to plastic. Another in the beverage industry cut downtime by 40% due to fewer corrosion-related leaks. These are real savings that translate to higher profits and happier stakeholders.

Beyond the Balance Sheet

While ROI is a critical metric, the benefits of plastic bag filter housings extend beyond financial statements. Their lightweight design reduces shipping costs and installation time. Their corrosion resistance means fewer environmental hazards from leaks or spills. And their longer lifespan reduces waste, aligning with sustainability goals. When you choose plastic, you’re not just saving money; you’re investing in a smarter, safer, and greener future.

The math doesn’t lie: plastic bag filter housing advantages shine brightest when viewed through a full-lifecycle lens. With 30-50% lower initial costs, 40% reduced maintenance expenses, and 2-3 year payback periods in typical applications, these housings deliver measurable ROI that metal simply can’t match. But don’t just take our analysis at face value—download our free cost optimization guide to run your specific scenario. Ready to transform how you view filtration investments? Share this breakdown with your procurement team and let’s start a conversation about smarter spending. After all, in industrial efficiency, every percentage point of cost reduction compounds into competitive advantage.