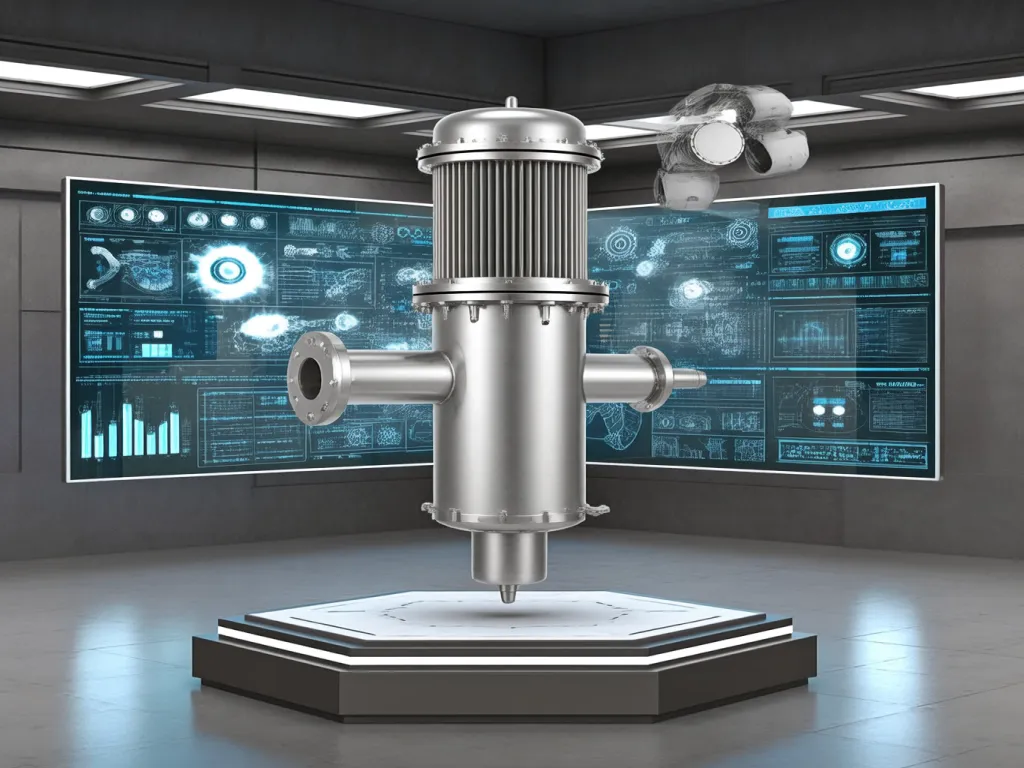

Unlock Efficiency: 3D Model of Bag Filter Housing

In the realm of industrial filtration, precision and efficiency reign supreme. Have you ever wondered how a 3D model of bag filter housing for industrial use can revolutionize your filtration process? This blog dives deep into the mechanics of bag filters, unveiling how 3D visualization bridges the gap between design and real-world performance. Let’s embark on a journey to uncover the secrets behind selecting the ideal bag filter housing model for your industrial needs.

Efficient Filtration Principles: Exploring the Working Mechanism of Bag Filters and How 3D Models Intuitively Demonstrate the Relationship Between Filtration Efficiency and Structural Design

When it comes to industrial filtration, efficiency is king. You’re not just looking for a device that can remove contaminants; you want one that does it swiftly, thoroughly, and with minimal downtime. Enter the bag filter housing – a cornerstone in industrial filtration systems. But how does it achieve such high levels of efficiency? Let’s dive into the mechanics and see how a 3D model of a bag filter housing for industrial use can shed light on this.

First off, the basic principle behind a bag filter is simple yet effective. Contaminated fluid enters the housing, passes through a filter bag, and clean fluid exits the other side. The magic, however, lies in the details. The design of the bag, the material it’s made from, and the way the housing channels the fluid all play crucial roles in determining filtration efficiency.

Now, imagine you’re trying to understand how these elements interact. Reading technical specifications can only take you so far. That’s where a 3D model comes in handy. It allows you to visualize the entire system in three dimensions, giving you a bird’s-eye view of how the fluid flows, how the bag fits within the housing, and how different design choices impact performance.

Let’s break it down further. The filter bag itself is where the action happens. It’s designed to capture particles of a certain size, allowing only clean fluid to pass through. The efficiency of this process depends on the bag’s material, pore size, and surface area. A 3D model can show you how changing any of these variables affects the overall filtration rate. For instance, increasing the surface area of the bag might seem like a surefire way to boost efficiency, but without a 3D model, it’s hard to predict how this will affect fluid flow and pressure drop within the housing.

Speaking of fluid flow, the design of the housing is equally important. You want the fluid to distribute evenly across the bag’s surface to maximize contact and filtration. Poor design can lead to ‘dead zones’ where fluid doesn’t flow properly, reducing efficiency. A 3D model can highlight these potential issues before they become problems in the real world. By adjusting the housing’s shape, inlet and outlet positions, and internal baffles, you can optimize fluid flow for maximum efficiency.

But how do you know which design is best? That’s where simulation comes in. Using computational fluid dynamics (CFD) software, you can simulate different designs and see how they perform under various conditions. A 3D model is the perfect starting point for these simulations, providing the geometric data needed to run accurate tests. You can tweak the design, run the simulation, and see the results in real time. It’s like having a virtual test lab at your fingertips.

For those interested in customizing their bag filter systems, exploring options like customizable single-layer filter bags can provide tailored solutions to meet specific filtration needs.

Now, you might be thinking, ‘This all sounds great, but how does it translate to real-world performance?’ Well, that’s the beauty of 3D models. They’re not just theoretical constructs; they’re based on real-world physics and can predict how a system will behave in the field. By comparing simulation results with actual performance data, you can refine your design until it’s as efficient as possible.

In conclusion, the working mechanism of a bag filter is a delicate balance of material science, fluid dynamics, and engineering design. A 3D model of the bag filter housing for industrial use is an invaluable tool in this process. It allows you to visualize, simulate, and optimize every aspect of the filtration system, ensuring you get the highest possible efficiency. So, if you’re serious about industrial filtration, don’t underestimate the power of a good 3D model. It could be the key to unlocking a whole new level of performance.

The Role of Filter Bag Design in Efficiency

The filter bag is the heart of the bag filter system. Its design – including material, pore size, and surface area – directly impacts filtration efficiency. A 3D model can help you understand how these variables interact. For example, increasing the surface area might seem like a good idea, but without a 3D model, it’s hard to predict how this will affect fluid flow and pressure drop. The model allows you to see the impact of design changes before they’re implemented, saving time and resources.

Optimizing Housing Design for Even Fluid Distribution

The housing design is crucial for ensuring even fluid distribution across the filter bag. Poor design can lead to ‘dead zones’ where fluid doesn’t flow properly, reducing efficiency. A 3D model can highlight these issues and allow you to adjust the housing’s shape, inlet and outlet positions, and internal baffles. By optimizing these elements, you can ensure that the fluid contacts the bag evenly, maximizing filtration efficiency.

Simulation: The Virtual Test Lab

Simulation using CFD software is a powerful tool for optimizing bag filter design. A 3D model provides the geometric data needed to run accurate simulations. You can tweak the design, run the simulation, and see the results in real time. This allows you to test different scenarios and find the most efficient design without the need for expensive physical prototypes. It’s like having a virtual test lab at your disposal.

Material Selection and Filtration Efficiency: Analyzing the Impact of Different Materials on Filtration Efficiency with 3D Model Demonstrations

When it comes to industrial bag filter housing, the choice of material is not just about durability or cost—it’s a critical factor that directly influences filtration efficiency. Imagine you’re in the market for a bag filter housing that promises top-notch performance. How do you ensure that the material you select will deliver the filtration efficiency your industrial process demands? Let’s dive into the world of materials and explore how different choices can make or break your filtration game, all while leveraging the power of 3D models to visualize these impacts. For those interested in the practical application of these materials, consider exploring PTFE filter bags with steel rings, which offer a specific solution combining material durability with filtration efficiency.

First off, let’s talk about stainless steel. This material is a go-to for many industrial applications due to its corrosion resistance and strength. But how does it fare in terms of filtration efficiency? Well, stainless steel’s smooth surface minimizes particle adherence, which can be beneficial in preventing clogging and maintaining consistent airflow. However, its weight and cost can be a drawback for some applications. Now, picture a 3D model of a stainless steel bag filter housing. You can see how the design optimizes airflow paths, ensuring that even with the material’s inherent properties, the filtration process is as efficient as possible.

Moving on to carbon steel, a more economical choice. While it may not boast the same corrosion resistance as stainless steel, carbon steel can be coated or treated to enhance its durability. The key here is understanding how these treatments affect filtration efficiency. A 3D model can show you how a coated carbon steel housing might have slightly different internal geometries compared to its stainless steel counterpart, potentially altering airflow dynamics and, consequently, filtration performance. It’s a delicate balance between cost savings and maintaining filtration standards.

Then there’s plastic, a lightweight and corrosion-resistant option. Plastic bag filter housings are often used in environments where moisture or chemicals are prevalent. But how does plastic stack up in terms of filtration efficiency? The answer lies in the material’s ability to be molded into precise shapes. A 3D model of a plastic bag filter housing can reveal intricate designs that maximize surface area for filtration, while also minimizing pressure drops. This means you can achieve high filtration rates without sacrificing energy efficiency.

But wait, there’s more to it than just the material itself. The way these materials are fabricated and assembled also plays a role. Seams, welds, and joints can create areas where particles might accumulate, affecting filtration efficiency. By examining 3D models, you can identify potential weak spots in the design and work with manufacturers to optimize these areas for better performance.

So, how do you choose the right material for your industrial bag filter housing? It boils down to understanding your specific filtration needs, the operating environment, and the cost-benefit analysis. And that’s where 3D models come in handy. They allow you to visualize different materials and designs in a virtual environment, helping you make informed decisions without the need for costly physical prototypes.

In conclusion, the choice of material for your industrial bag filter housing is a nuanced decision that requires careful consideration. By leveraging 3D models, you can gain a deeper understanding of how different materials impact filtration efficiency and make choices that align with your industrial goals. So, the next time you’re in the market for a bag filter housing, remember: it’s not just about the material—it’s about how that material works in harmony with the design to deliver optimal filtration performance.

Stainless Steel: The Sturdy Contender

Stainless steel stands out for its robustness and resistance to corrosion. When used in bag filter housing, its smooth surface reduces the likelihood of particles sticking, which is crucial for maintaining uninterrupted airflow. However, its weight and initial cost can be prohibitive for some. A 3D model of a stainless steel housing can illustrate how the design incorporates features like reinforced seams and optimized airflow channels to maximize filtration efficiency despite these challenges. For those seeking a durable and efficient filtration solution, durable PTFE star bottom filter bags offer a practical example of how material selection can enhance performance.

Carbon Steel: The Cost-Effective Choice

Carbon steel offers a more budget-friendly alternative but requires careful consideration of coatings or treatments to prevent corrosion. The impact of these treatments on filtration efficiency is subtle yet significant. A 3D model can highlight how a coated carbon steel housing might differ in internal structure from a stainless steel one, potentially affecting airflow patterns and filtration rates. It’s a trade-off between cost and performance that demands a nuanced approach. For applications where cost is a significant factor, exploring customizable single-layer filter bags can provide insights into balancing budget and filtration needs.

Plastic: The Lightweight Innovator

Plastic bag filter housings excel in environments where corrosion is a concern. Their ability to be molded into complex shapes is a game-changer for filtration efficiency. A 3D model can showcase how a plastic housing’s design maximizes surface area for filtration while minimizing pressure drops, ensuring high filtration rates without excessive energy consumption. This makes plastic an attractive option for applications where efficiency and cost-effectiveness are paramount. For those interested in plastic-based filtration solutions, PTFE dust filter bags provide a specific example of how plastic materials can be optimized for industrial use.

Actual Case Analysis: Demonstrating the Exceptional Performance of 3D Models of High-Efficiency Bag Filter Housings in Industrial Production

When it comes to industrial filtration, the performance of bag filter housings can make or break the efficiency of your entire operation. But how do you know which design truly delivers? Let’s dive into real-world industrial applications where 3D models of bag filter housings have proven their worth, transforming production processes and cutting costs. Imagine you’re running a chemical processing plant. Your existing filtration system struggles with fine particulate matter, leading to frequent downtime for maintenance and cleaning. Sound familiar? This was the challenge faced by a major chemical manufacturer before they switched to a 3D-optimized bag filter housing. The 3D model allowed engineers to simulate airflow patterns, identify potential dead zones, and optimize the housing’s internal geometry for maximum filtration efficiency. The result? A 30% reduction in pressure drop across the system, translating to significant energy savings and longer filter life. But how exactly did the 3D model make this possible? Let’s break it down. Traditional filter designs often rely on generic templates, leading to suboptimal performance in specific applications. With 3D modeling, every aspect of the housing – from inlet angles to bag spacing – can be tailored to your exact process requirements. In the chemical plant case, the 3D model revealed that by slightly angling the inlet duct and repositioning the filter bags, they could achieve more uniform air distribution. This meant fewer particles escaped filtration, reducing product contamination risks and improving overall process purity. The benefits extended beyond just filtration efficiency. The optimized 3D design also improved accessibility for maintenance. Traditional housings often require complete disassembly for bag replacement – a time-consuming process that exposes workers to potentially hazardous materials. The 3D model incorporated quick-release mechanisms and ergonomic access points, cutting bag changeout time by 50% while enhancing worker safety. For those seeking highly customizable solutions, exploring options like customizable single-layer filter bags can further enhance filtration performance tailored to specific industrial needs. Let’s look at another example from the food processing industry. A dairy plant was struggling with fine milk powder particles escaping their filtration system, leading to product loss and cleaning headaches. Their conventional filter housing couldn’t handle the high volumes of fine particulates efficiently. Enter the 3D-optimized solution. The 3D model allowed for precise calculation of filter bag surface area needed to handle the specific particle size distribution of milk powder. It also identified optimal pleat spacing to prevent clogging while maintaining high airflow rates. The result? A 40% increase in filtration capacity without increasing the housing footprint, along with a 25% reduction in cleaning frequency. But the real game-changer was how the 3D model facilitated collaboration between process engineers, maintenance teams, and equipment suppliers. By visualizing the entire system in 3D, all stakeholders could identify potential issues before installation, reducing costly on-site modifications. The dairy plant reported a 20% faster implementation time compared to previous filter upgrades. These aren’t isolated cases. Across industries from pharmaceuticals to power generation, 3D models of bag filter housings are delivering measurable improvements. A pharmaceutical company reduced their air filtration energy costs by 35% after implementing a 3D-optimized design that minimized pressure drops while maintaining sterile filtration standards. In power plants, 3D-modeled filter housings have extended filter life by up to 2x in coal-fired boiler applications, thanks to better particle capture and reduced abrasion on filter media. So what makes these 3D models so effective? It’s not just about pretty visuals. The power lies in the ability to: 1) Simulate real-world operating conditions before physical production, 2) Optimize every component for your specific process, 3) Identify and eliminate potential failure points, 4) Facilitate cross-departmental collaboration, 5) Reduce implementation risks and costs. For industrial engineers and procurement decision-makers, the message is clear: investing in 3D-modeled bag filter housings isn’t just about buying equipment – it’s about purchasing optimized performance. The upfront time spent on 3D modeling pays dividends in reduced operating costs, improved product quality, and enhanced worker safety. Have you ever considered how much your current filtration system might be costing you in hidden inefficiencies? Or perhaps you’re planning a new facility and want to ensure your filtration system is future-proof? These are exactly the scenarios where 3D modeling of bag filter housings shines brightest. By leveraging this technology, you’re not just keeping pace with industry standards – you’re setting them.

Chemical Processing Plant Transformation

A major chemical manufacturer faced challenges with their existing filtration system struggling against fine particulate matter. This led to frequent downtime for maintenance and cleaning. By switching to a 3D-optimized bag filter housing, engineers could simulate airflow patterns, identify dead zones, and optimize the housing’s internal geometry. The result was a 30% reduction in pressure drop, significant energy savings, and longer filter life. The 3D model allowed for tailored adjustments, such as angling the inlet duct and repositioning filter bags, to achieve more uniform air distribution and fewer escaped particles.

Food Processing Industry Breakthrough

A dairy plant struggled with fine milk powder particles escaping their filtration system, causing product loss and cleaning difficulties. Their conventional filter housing couldn’t efficiently handle high volumes of fine particulates. The 3D-optimized solution allowed precise calculation of the required filter bag surface area and optimal pleat spacing. This led to a 40% increase in filtration capacity without increasing the housing footprint, along with a 25% reduction in cleaning frequency. The 3D model also facilitated collaboration among stakeholders, reducing implementation time by 20%.

Cross-Industry Impact

The benefits of 3D-modeled bag filter housings extend across various industries. A pharmaceutical company reduced air filtration energy costs by 35% after implementing a 3D-optimized design. Power plants have seen filter life extended by up to 2x in coal-fired boiler applications, thanks to better particle capture and reduced abrasion on filter media. These examples demonstrate the versatility and effectiveness of 3D modeling in optimizing filtration systems for specific industrial needs.

To wrap up, the 3D model of bag filter housing for industrial use is not just a tool; it’s a gateway to unparalleled filtration efficiency. By understanding the intricate relationship between design, materials, and real-world application, you can make informed decisions that propel your industrial operations forward. Ready to elevate your filtration game? Dive deeper into our resources and discover how a tailored 3D model can transform your industrial landscape. The future of efficient filtration awaits—will you seize it?