Ultimate Guide: Pick the Right durable PVC bag filter housing

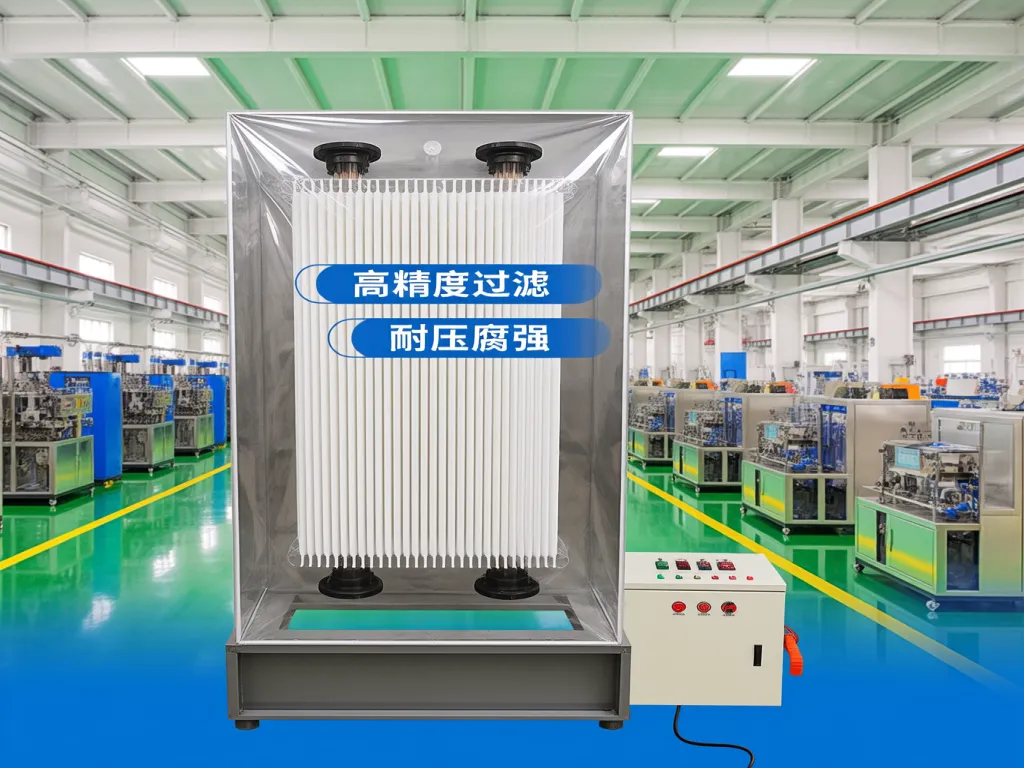

When it comes to industrial filtration, choosing the right equipment can make or break your operations. Enter the world of durable PVC bag filter housing—a game-changer for industries demanding precision, longevity, and reliability. But how do you navigate the maze of options to find the perfect fit for your needs? In this guide, we’ll dissect the key performance parameters that set apart a top-tier durable PVC bag filter housing from the rest. From filtration accuracy to pressure resistance and corrosion resilience, we’ve got you covered. Ready to elevate your filtration game? Let’s dive in!

Filtration Accuracy: Impact on Performance and How to Choose the Right One

When it comes to selecting a durable PVC bag filter housing, filtration accuracy is one of the most critical parameters to consider. But what exactly is filtration accuracy, and why does it matter so much? Let’s break it down. Filtration accuracy refers to the size of particles that a filter can effectively capture. It’s usually measured in microns (μm). The smaller the micron rating, the finer the filtration—meaning the filter can trap smaller particles. For example, a 1-micron filter will remove much finer particles than a 10-micron filter. So, how does this affect your filtration system? Choosing the right filtration accuracy can make or break your process efficiency. If the filter is too coarse (high micron rating), unwanted particles may slip through, contaminating your product or process stream. On the other hand, if the filter is too fine (low micron rating), it may clog quickly, leading to frequent replacements, increased downtime, and higher operational costs.

Now, you might be wondering: ‘How do I know which filtration accuracy is right for my application?’ Great question! The answer depends heavily on your specific use case. Let’s explore some common scenarios where different filtration accuracies shine. In water treatment applications, for instance, coarse filtration (around 10–50 μm) is often sufficient to remove visible debris and larger sediments. This level of filtration helps protect downstream equipment from damage while maintaining adequate flow rates. However, in pharmaceutical manufacturing, where purity is paramount, ultra-fine filtration (below 1 μm) may be necessary to ensure compliance with strict quality standards. Chemical processing plants present another unique challenge. Here, the choice of filtration accuracy must balance both particle removal and chemical compatibility.

But wait—there’s more! Did you know that filtration accuracy also impacts the lifespan of your filter housing? A properly matched filtration accuracy ensures optimal performance and extends the service life of your equipment. Conversely, mismatched filtration can lead to premature wear and tear, forcing you to replace components sooner than expected. So, how can you determine the ideal filtration accuracy for your needs? Start by analyzing your process requirements. What types of contaminants are present? What is the acceptable level of impurity in your final product? Are there regulatory standards you must adhere to? Once you have a clear understanding of these factors, consult with experts or refer to industry guidelines such as those from the EPA to narrow down your options. Remember, choosing the right filtration accuracy isn’t just about technical specifications—it’s about finding a balance between effectiveness, efficiency, and cost.

By taking the time to evaluate your application thoroughly, you can select a durable PVC bag filter housing that delivers consistent performance and long-term value. Still unsure? Don’t worry! Many suppliers offer testing services to help you validate the best filtration accuracy for your setup. This hands-on approach allows you to see real-world results before making a final decision. In summary, filtration accuracy plays a pivotal role in the performance of your durable PVC bag filter housing. By understanding its impact and aligning it with your application’s demands, you can optimize your filtration system for maximum efficiency and reliability. Ready to take the next step? Let’s dive deeper into how filtration accuracy interacts with other key parameters like pressure resistance and corrosion resistance in the upcoming sections!

Pressure Resistance: Analyzing the Relationship Between Pressure Resistance and Housing Lifespan, and How to Evaluate Housing Stability in High-Pressure Environments

When it comes to choosing a durable PVC bag filter housing, pressure resistance isn’t just a number on a spec sheet—it’s a critical factor that directly impacts the lifespan and reliability of your filtration system. Think about it: if your filter housing can’t handle the pressure demands of your application, you’re looking at premature failure, costly downtime, and potentially hazardous leaks. So, how exactly does pressure resistance tie into the overall lifespan of a PVC bag filter housing? Let’s break it down.

First, the relationship between pressure resistance and housing lifespan is rooted in material science. PVC, or polyvinyl chloride, is a thermoplastic polymer known for its durability and chemical resistance. However, not all PVC is created equal. The pressure rating of a PVC bag filter housing depends on the quality of the PVC used, its thickness, and the manufacturing process. A higher-quality PVC with a thicker wall can withstand greater internal pressures without deforming or cracking, thus extending the housing’s useful life.

But how do you know if a housing can truly handle the pressure? The answer lies in rigorous testing and certification. Manufacturers subject their PVC bag filter housings to hydrostatic pressure tests, where the housing is filled with water and pressurized to levels far exceeding its rated capacity. If the housing can maintain its structural integrity without any signs of leakage or deformation, it earns its pressure rating. This testing is crucial because it gives you, the end-user, confidence that the housing won’t fail under normal operating conditions.

Now, let’s talk about evaluating housing stability in high-pressure environments. It’s not just about the pressure rating; it’s also about how the housing behaves under sustained pressure. Some housings may handle short bursts of high pressure well but struggle over time as the material fatigues. This is where long-term pressure cycling tests come into play. By subjecting the housing to repeated cycles of high and low pressure, manufacturers can simulate years of real-world use and identify any potential weaknesses in the design.

But you don’t have to rely solely on manufacturer data. As a savvy buyer, you can perform your own due diligence. Start by reviewing case studies and industry reports that detail the performance of PVC bag filter housings in similar applications. Look for patterns—do certain designs or materials consistently outperform others in high-pressure scenarios? Additionally, consider reaching out to peers in your industry for firsthand accounts of their experiences with different housings.

Another key factor to consider is the operating environment. High-pressure applications often come hand-in-hand with other challenges, like extreme temperatures or corrosive chemicals. These factors can accelerate material degradation and reduce the effective lifespan of your filter housing. That’s why it’s essential to choose a housing that’s not only rated for the pressure you need but also designed to withstand the specific conditions of your application.

So, how do you balance all these factors to make an informed decision? Start by defining your application’s pressure requirements. What’s the maximum pressure your system will generate? How often will it reach those levels? Once you have those numbers, look for housings with pressure ratings that exceed your needs by a comfortable margin. This provides a safety buffer and accounts for any unexpected pressure spikes.

Next, consider the material quality and thickness. Don’t be swayed by low prices if they come at the expense of durability. Investing in a higher-quality PVC bag filter housing may cost more upfront, but it will save you money in the long run by reducing downtime and maintenance costs.

Finally, don’t overlook the importance of proper installation and maintenance. Even the most durable housing won’t perform well if it’s not installed correctly or if it’s neglected over time. Follow the manufacturer’s guidelines for installation and set up a regular maintenance schedule to inspect for signs of wear or damage.

In conclusion, pressure resistance is a cornerstone of durable PVC bag filter housing performance. By understanding the relationship between pressure resistance and housing lifespan, evaluating housing stability in high-pressure environments, and considering the specific demands of your application, you can choose a filter housing that delivers reliable, long-lasting performance.

Corrosion Resistance: Comparing Performance of Different PVC Materials in Corrosive Media and How Enhanced PVC Improves Corrosion Resistance

When it comes to selecting a durable PVC bag filter housing, corrosion resistance is a critical factor that can’t be overlooked. After all, you want your investment to withstand the test of time and harsh environmental conditions. So, let’s dive deep into how different PVC materials perform in corrosive media and how enhanced PVC takes corrosion resistance to the next level.

First off, not all PVCs are created equal. There are several types of PVC materials used in manufacturing bag filter housings, each with its own set of properties. Standard PVC, for instance, is widely used due to its affordability and decent resistance to many chemicals. However, when exposed to highly corrosive substances like strong acids or alkalis, standard PVC can start to degrade over time. This degradation can lead to leaks, reduced filtration efficiency, and ultimately, a shorter lifespan for your filter housing.

Now, let’s talk about chlorinated PVC (CPVC). CPVC is a step up from standard PVC in terms of corrosion resistance. It’s been chemically treated to increase its chlorine content, which in turn enhances its ability to withstand harsher chemicals. CPVC filter housings are a great choice for applications involving moderately corrosive media, offering a longer service life compared to standard PVC.

But what if you’re dealing with extremely corrosive environments? Enter enhanced PVC, also known as reinforced or modified PVC. This material takes corrosion resistance to a whole new level. Enhanced PVC is formulated with special additives that create a protective barrier on the surface, making it highly resistant to even the most aggressive chemicals. These additives can include antioxidants, UV stabilizers, and corrosion inhibitors, all working together to extend the life of your filter housing. For those seeking even more specialized filtration solutions, exploring options like PTFE filter bags can provide additional resistance and durability in highly corrosive settings.

So, how does enhanced PVC achieve such impressive corrosion resistance? It’s all about the chemistry. The additives in enhanced PVC react with the corrosive media to form a passive layer on the surface. This layer acts as a shield, preventing the corrosive substances from penetrating the material and causing damage. As a result, enhanced PVC filter housings can last significantly longer in corrosive environments, reducing the need for frequent replacements and saving you money in the long run.

But don’t just take my word for it. Let’s look at some real-world examples. In the chemical processing industry, where corrosive substances are a daily occurrence, enhanced PVC filter housings have proven their worth time and again. Companies that have switched to enhanced PVC report fewer leaks, longer service intervals, and overall better performance compared to standard or even CPVC alternatives.

Now, you might be wondering, ‘How do I know if enhanced PVC is right for my application?’ Well, it all comes down to the specific corrosive media you’re dealing with and the operating conditions of your facility. If you’re working with mildly corrosive substances, standard or CPVC might suffice. But if you’re facing highly aggressive chemicals or extreme temperatures, enhanced PVC is definitely worth considering.

In conclusion, when it comes to corrosion resistance in PVC bag filter housings, not all materials are created equal. Standard PVC offers basic protection, CPVC steps it up a notch, and enhanced PVC takes corrosion resistance to the next level. By understanding the properties of each material and how they perform in different corrosive environments, you can make an informed decision that ensures the longevity and efficiency of your filtration system.

Standard PVC vs. CPVC: A Quick Comparison

Before we dive deeper into enhanced PVC, let’s quickly compare standard PVC and CPVC. Standard PVC is the most basic form, offering good resistance to many chemicals but struggling with highly corrosive substances. CPVC, on the other hand, has been chemically modified to increase its chlorine content, enhancing its corrosion resistance. This makes CPVC a better choice for moderately corrosive environments. However, when it comes to extreme conditions, neither standard PVC nor CPVC can match the performance of enhanced PVC.

The Science Behind Enhanced PVC’s Corrosion Resistance

So, what makes enhanced PVC so resistant to corrosion? It’s all about the additives. These special compounds are mixed into the PVC during manufacturing to create a protective barrier on the surface. When exposed to corrosive media, the additives react to form a passive layer that prevents the chemicals from penetrating the material. This passive layer is self-healing, meaning it can reform if damaged, ensuring continuous protection. The result? A filter housing that can withstand even the harshest environments without degrading.

Real-World Applications of Enhanced PVC Filter Housings

Still not convinced? Let’s look at some real-world applications where enhanced PVC filter housings have made a significant difference. In the pharmaceutical industry, for example, where cleanliness and corrosion resistance are paramount, enhanced PVC has become the material of choice. Similarly, in the food and beverage sector, where corrosive cleaning agents are used regularly, enhanced PVC filter housings offer superior durability and performance. These examples demonstrate how enhanced PVC can meet the demands of even the most challenging applications.

Armed with insights into filtration accuracy, pressure resistance, and corrosion resilience, you’re now equipped to make an informed choice on durable PVC bag filter housing. Remember, the right housing not only boosts your filtration efficiency but also extends your equipment’s lifespan. So, why wait? Take the leap and transform your industrial filtration setup today. And if you’re hungry for more, keep exploring—there’s always a better, more efficient solution waiting around the corner. Your journey to optimal filtration starts now!