Description

Delivering superior filtration performance while reducing operational costs and enhancing environmental compliance.

Industries-Boost Efficiency with Top Filters

High Efficiency Filtration

Captures 99.9% of particulates, ensuring cleaner air and compliance with environmental standards.

Cost-Effective Solution

Industrial bag filter price range offers competitive pricing without compromising on quality, reducing total cost of ownership.

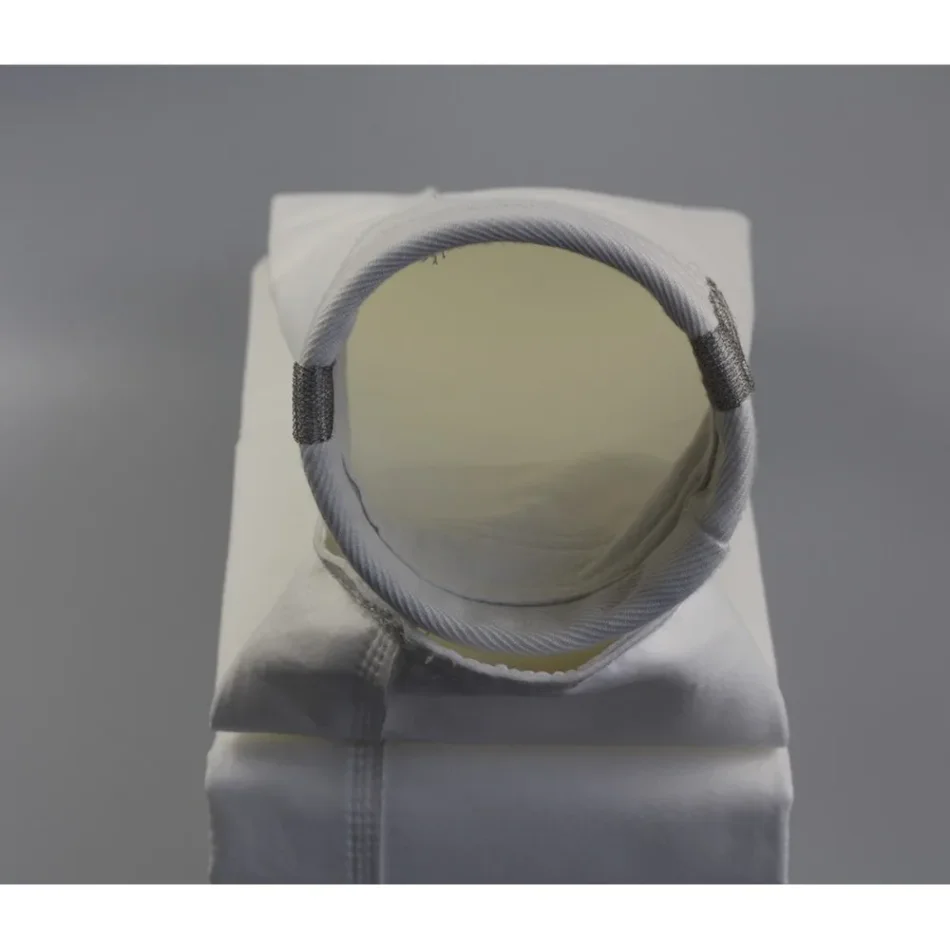

Durable Polyester Construction

Made from premium polyester, these filtration bags withstand high temperatures and harsh conditions, extending service life.

Easy Maintenance & Replacement

Designed for quick and hassle-free replacement, minimizing downtime and maintenance costs.

Features

Our industrial bag filter features a needle-felt construction with a polyester fibre and scrim composition. The felt area weight is 500g/m² (±5%), with a thickness of 1.8-1.9mm. It boasts a mean air permeability of 14-16 m³/m²/min at 12.7mmH2O, ensuring efficient airflow. The breaking strength is 900 N/5cm (warp) and 1300 N/5cm (weft), with breaking elongations of 20% (warp) and 39% (weft). Dry shrinkage is less than 1.5% at 130°C for both warp and weft. Operating temperatures are below 130°C, with recommended maximum continuous and surge temperatures of 150°C. The finish is heat set, singed, and calendared for enhanced durability.

Benefits

The high efficiency of our industrial bag filter ensures cleaner air, reducing the risk of health hazards and environmental pollution. Its cost-effectiveness lowers operational expenses, while the durable construction extends the filter’s lifespan, reducing replacement frequency. Easy maintenance and replacement minimize downtime, enhancing overall productivity. These benefits make our industrial bag filter the best choice for industries seeking reliable and efficient filtration solutions.

Use Cases

Our industrial bag filter is widely used in the cement industry for dust collection and particulate control. It is also suitable for other industrial applications where high-efficiency filtration is required, such as power generation, steel manufacturing, and chemical processing. The filter’s ability to withstand high temperatures and harsh conditions makes it ideal for environments with extreme operating conditions.

|

Item

|

industrial bag filter cost and dust filter bags china

|

|

Construction

|

Needle felt

|

|

Fibre Composition

|

Polyester

|

|

Scrim Composition

|

Polyester

|

|

Felt Area Weight

|

500g/m2(±5%)

|

|

Thickness

|

1.8-1.9mm

|

|

Mean Air Permeability

|

14-16 m3/m2/min 12.7mmH2O

|

|

Breaking Strength-MD(warp)

|

900 N / 5cm

|

|

Breaking Strength-CMD(weft)

|

1300 N / 5cm

|

|

Breaking Elongation( N/5cm)-MD(warp)

|

20%

|

|

Breaking Elongation( N/5cm)-CMD(weft)

|

39%

|

|

Dry Shrinkage MD(130℃warp)

|

<1.5%

|

|

Dry Shrinkage CMD(130℃weft)

|

<1.5 %

|

|

Operating Temperatures

|

<130 deg C

|

|

Recommended Maximum Continuous

|

150deg C

|

|

Recommended Maximum Surge

|

150deg C

|

|

Finish

|

Heat set, singed, calendared

|

Why Choose Our Industrial Bag Filter?

Our industrial bag filter offers unmatched efficiency, durability, and cost-effectiveness. Designed for harsh industrial environments, it ensures cleaner air and compliance with environmental standards, reducing operational costs and enhancing productivity.

How Does It Compare to Other Filters?

Compared to other filters, our industrial bag filter stands out with its superior filtration performance, durable construction, and easy maintenance. It captures more particulates, lasts longer, and requires less downtime for replacement, making it the best choice for industries seeking reliable filtration solutions.

What Industries Can Benefit?

Industries such as cement, power generation, steel manufacturing, and chemical processing can greatly benefit from our industrial bag filter. Its ability to withstand high temperatures and harsh conditions makes it ideal for environments with extreme operating conditions, ensuring efficient and reliable filtration.