Description

Enhance productivity and quality in filter bag manufacturing with our high-efficient three needle sewing machine.

Filter Bag Makers – Boost Efficiency with Precision Sewing

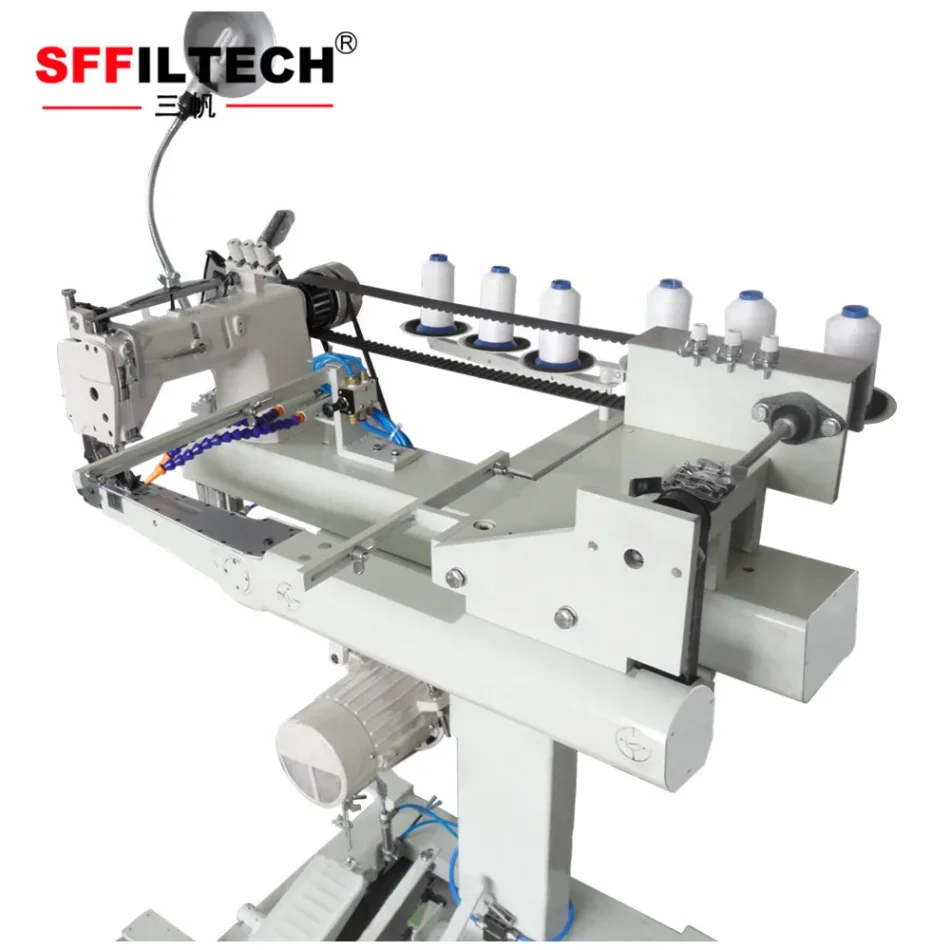

Cantilever Tubular Structure

Optimized for tube bag sewing, ensuring seamless and efficient production.

Pneumatic Puller System

Equipped with auto press lifter, scrap intake, and puller lifter for enhanced automation.

Auto Needle Cooling

Prevents needle overheating, ideal for sewing extra-thick materials.

Vertical Large Hook

Improves working efficiency, reducing downtime and increasing output.

Built-in Upper Feed Mechanism

Prevents oil splash, ensuring a clean and safe working environment.

Features

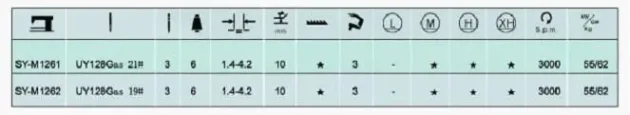

Our Three Needle Sewing Machine features a cantilever tubular structure, pneumatic puller system with auto press lifter, scrap intake, and puller lifter. It also includes an auto needle cooling function, vertical large hook, and a built-in upper feed mechanism to prevent oil splash. The machine is designed for precision sewing of filter bags, suits, and other heavy-duty materials.

Benefits

By using our Three Needle Sewing Machine, manufacturers can significantly enhance their production efficiency and quality. The pneumatic puller system and auto functions reduce manual labor, while the vertical large hook and built-in upper feed mechanism ensure smooth and clean sewing. The auto needle cooling function extends the machine’s lifespan, especially when working with extra-thick materials.

Use Cases

This sewing machine is ideal for manufacturing needle-punched felt, filter bags, men’s suits, work suits, and other medium to heavy-weight materials. It is particularly suited for sewing curved products like cushions, boots, luggage bags, and handbags. Its versatility and efficiency make it a valuable asset in various industries, including textile, leather, and synthetic fabric manufacturing.

Why Choose Our Three Needle Sewing Machine?

Our machine is designed for precision and efficiency in filter bag production. With its pneumatic puller system, auto functions, and vertical large hook, it ensures seamless sewing of heavy-duty materials.

What Makes Our Machine Stand Out?

The auto needle cooling function and built-in upper feed mechanism prevent overheating and oil splash, respectively, enhancing the machine's durability and cleanliness. Its cantilever tubular structure is optimized for tube bag sewing.

Where Can Our Machine Be Applied?

Our Three Needle Sewing Machine is versatile, suitable for manufacturing filter bags, suits, and other heavy-duty materials in textile, leather, and synthetic fabric industries.