Description

Providing durable, high-performance filtration solutions that enhance industrial efficiency and reduce maintenance costs.

Industries-Boost Efficiency with Durable Filtration

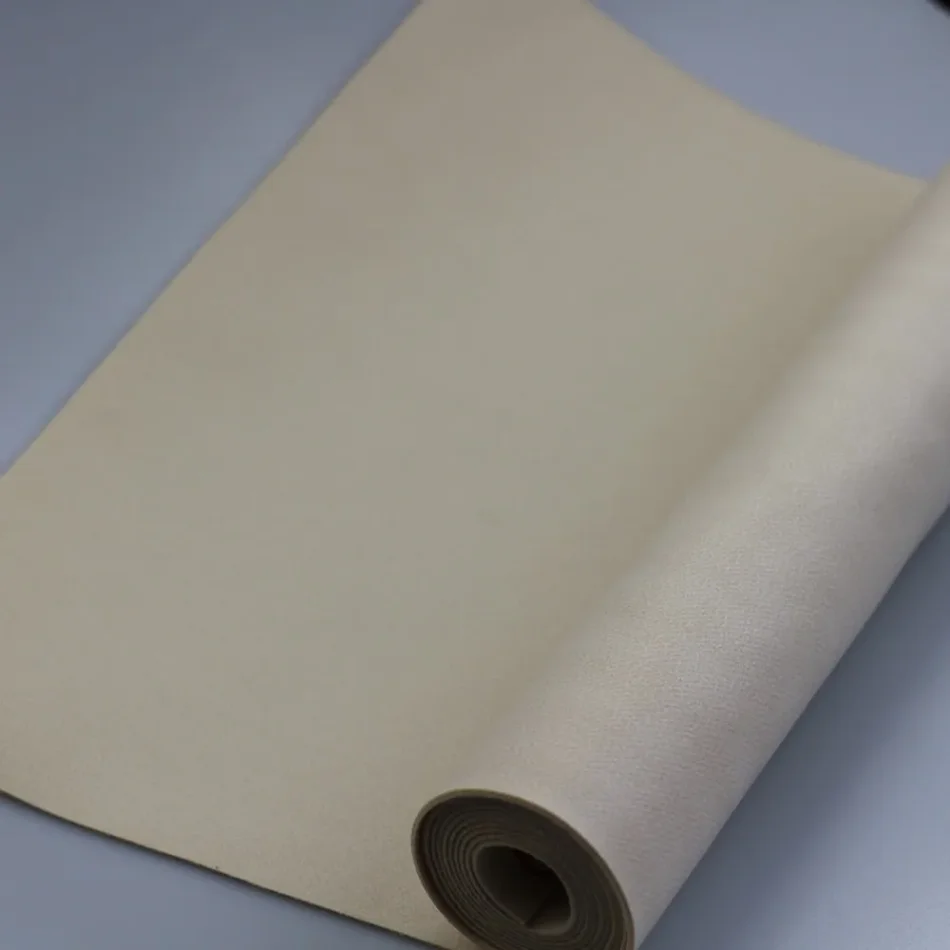

500gsm Aramid Fiber Composition

Ensures superior strength and durability, withstanding high temperatures up to 240°C continuously.

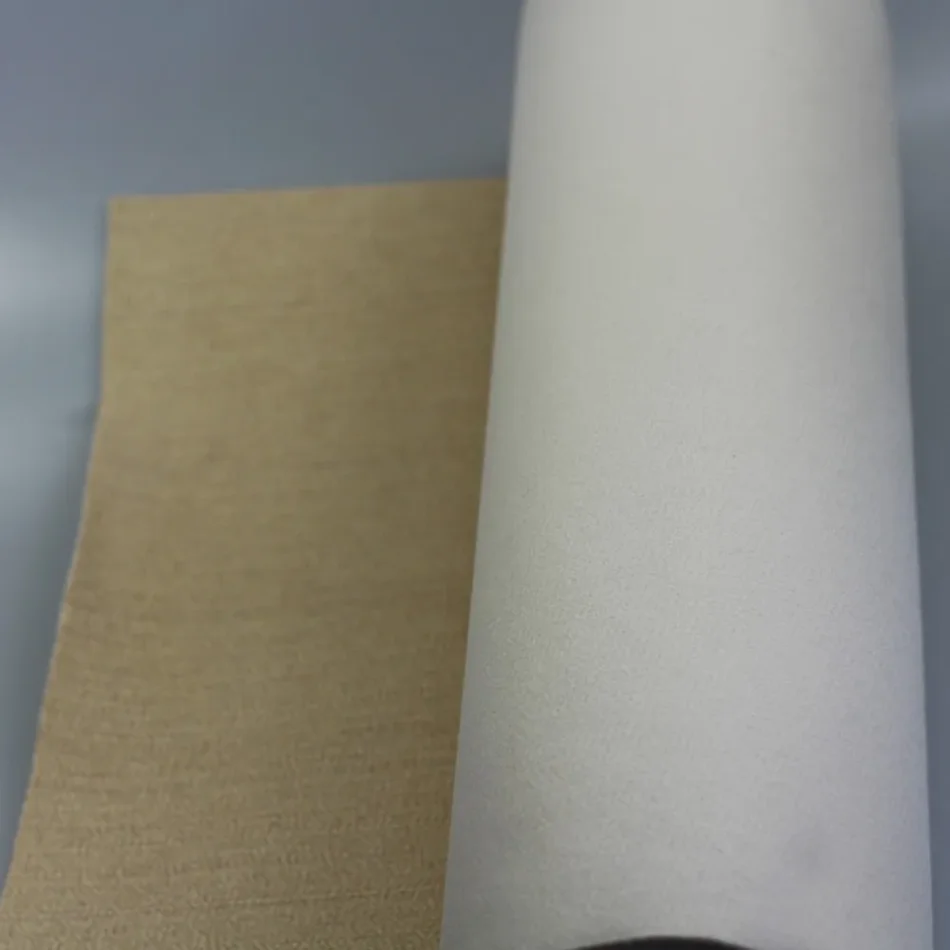

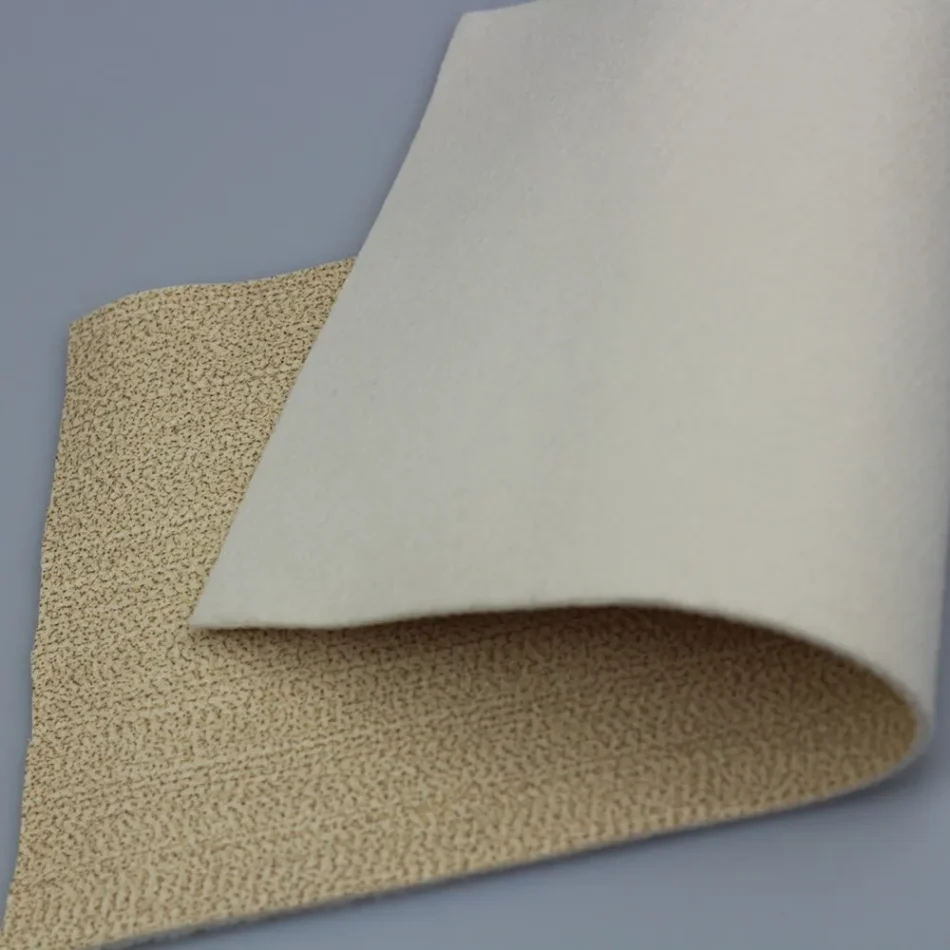

Needle Felt Construction

Enhances filtration efficiency and air permeability (15-17 m³/m²/min), ideal for fine particle capture.

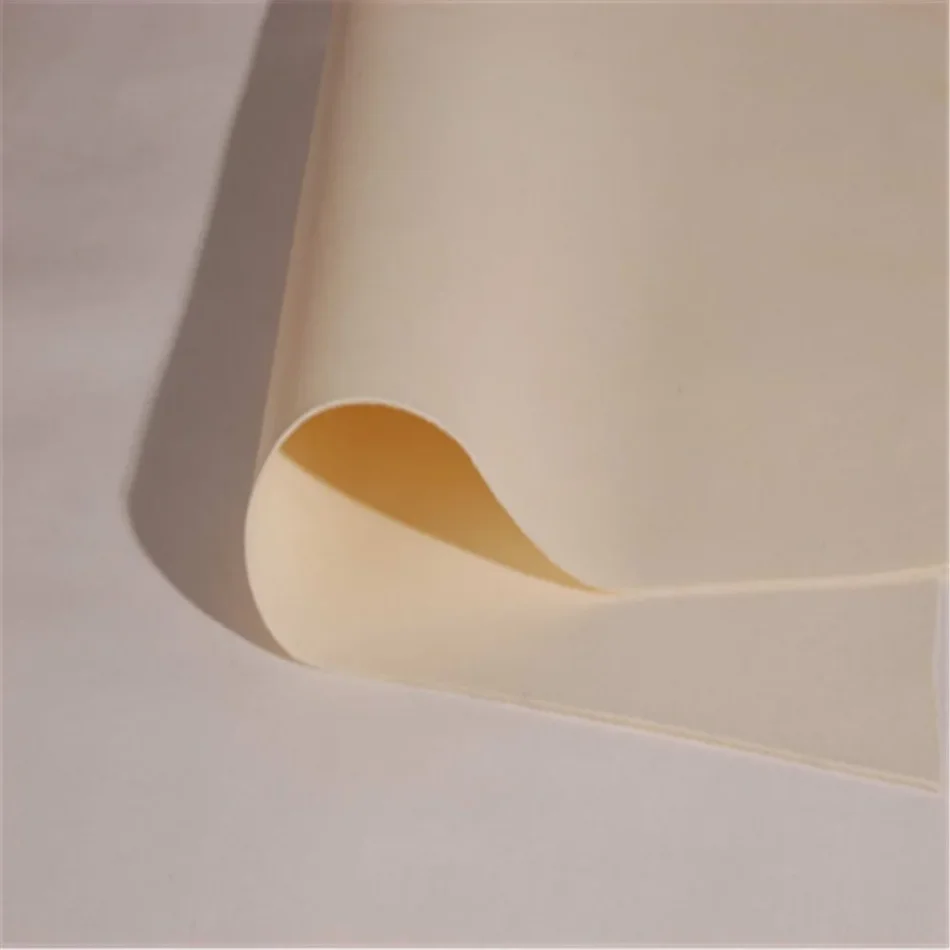

Heat Set, Singed, Calendared Finish

Provides a smooth surface, reducing particle adhesion and extending filter bag lifespan.

Low Dry Shrinkage (<1.5%)

Maintains dimensional stability under extreme temperatures, ensuring consistent performance.

Features

The Non-Woven Polyester Felt is crafted from 500gsm aramid fibers, featuring a needle felt construction that enhances its structural integrity. It boasts a mean air permeability of 15-17 m³/m²/min, facilitating efficient airflow while capturing fine particles. The filter felt undergoes a specialized finish, including heat setting, singeing, and calendaring, to improve its surface properties and durability.

Benefits

This filtration solution offers exceptional durability and high-temperature resistance, making it ideal for demanding industrial environments. Its superior air permeability enhances filtration efficiency, reducing energy consumption and maintenance costs. The low dry shrinkage ensures consistent performance over time, even under extreme temperature conditions, providing a reliable and cost-effective filtration solution.

Use Cases

The Non-Woven Polyester Felt is widely used in industrial dust collection systems, particularly in high-temperature environments such as asphalt mixing plants, biomass power stations, and coal-fired power stations. It is also suitable for chemical and pharmaceutical industries, food processing, and non-ferrous metal and steel production, where efficient and reliable filtration is crucial for maintaining operational efficiency and product quality.

|

Item

|

500gsm aramid filter felt

|

|

Construction

|

Needle felt

|

|

Fibre Composition

|

aramid

|

|

Scrim Composition

|

aramid

|

|

Felt Area Weight

|

500g/m2(±5%)

|

|

Thickness

|

1.8-1.9mm

|

|

15-17Mean Air Permeability

|

15-17 (m³/m²/min)

|

|

Breaking Strength-MD(warp)

|

900 N / 5cm

|

|

Breaking Strength-CMD(weft)

|

1200 N / 5cm

|

|

Breaking Elongation( N/5cm)-MD(warp)

|

20%

|

|

Breaking Elongation( N/5cm)-CMD(weft)

|

39%

|

|

Dry Shrinkage MD(130℃warp)

|

<1.5%

|

|

Dry Shrinkage CMD(130℃weft)

|

<1.5 %

|

|

Operating Temperatures

|

<204 deg C

|

|

Recommended Maximum Continuous

|

240deg C

|

|

Recommended Maximum Surge

|

240deg C

|

|

Finish

|

Heat set, singed, calendared membrane

|

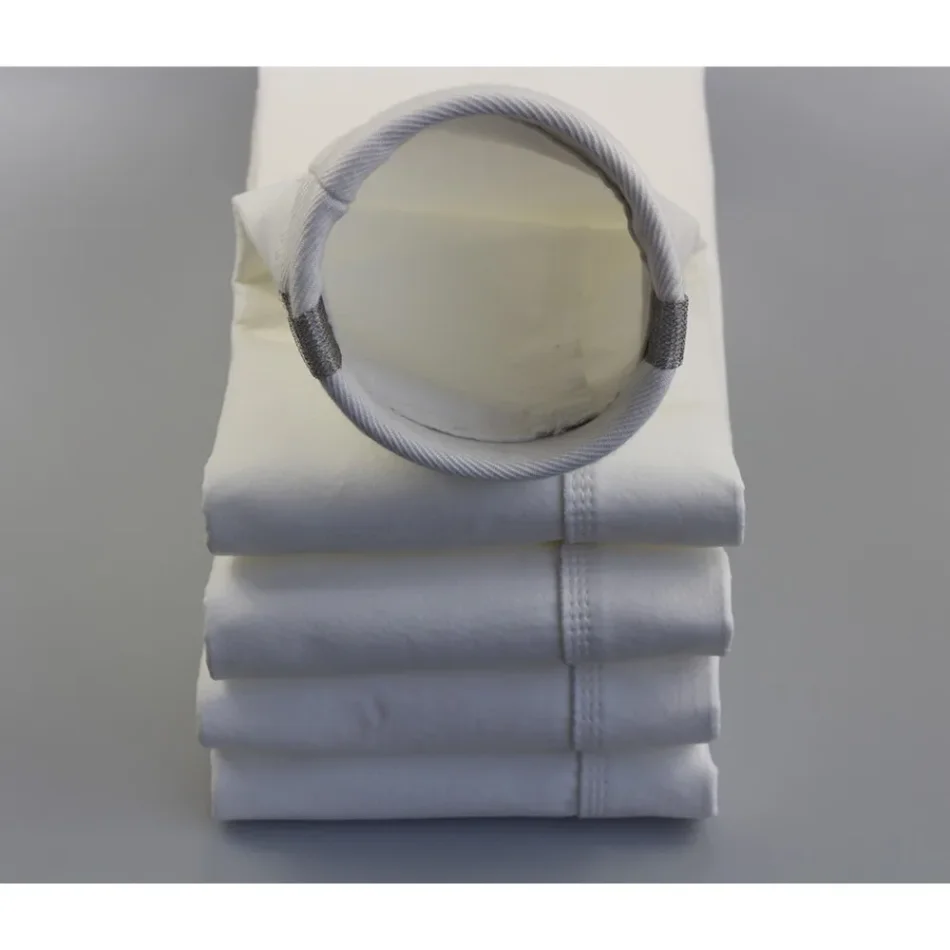

Why Choose Non-Woven Polyester Felt?

Non-Woven Polyester Felt offers superior durability and high-temperature resistance, making it ideal for demanding industrial filtration applications. Its needle felt construction and specialized finish enhance filtration efficiency and extend filter bag lifespan, reducing maintenance costs and improving operational efficiency.

Key Features of Non-Woven Polyester Felt

The filter felt is crafted from 500gsm aramid fibers, featuring a needle felt construction and a specialized finish. It boasts exceptional air permeability (15-17 m³/m²/min) and low dry shrinkage (<1.5%), ensuring consistent performance under extreme temperature conditions.

Applications of Non-Woven Polyester Felt

This filtration solution is widely used in industrial dust collection systems, including asphalt mixing plants, biomass power stations, and coal-fired power stations. It is also suitable for chemical and pharmaceutical industries, food processing, and non-ferrous metal and steel production.