Description

Our liquid filtration bags provide precision filtration, ensuring clean and pure liquids for industrial use.

Industries – Achieve Fine Filtration with Precision Bags

1 Micron Precision

Ensures ultra-fine filtration, removing even the smallest particles for superior liquid purity.

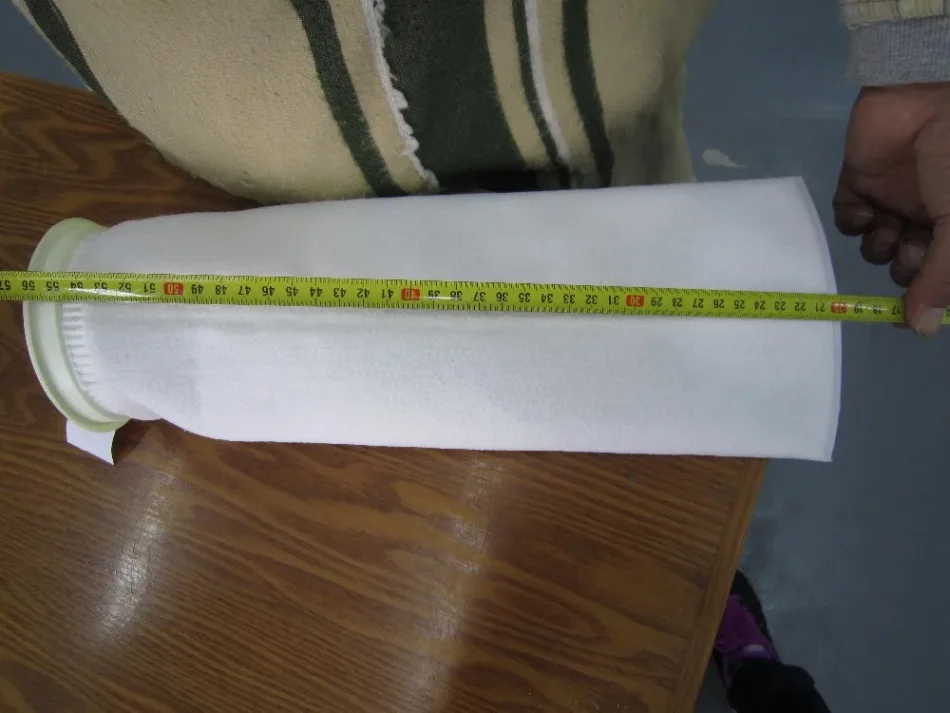

Customizable Sizes

Offers a range of small size liquid filtration bags to fit various tanks and systems, ensuring flexibility and adaptability.

Industrial-Grade Materials

Constructed from durable PE, PP, and NMO materials, these bags withstand harsh industrial environments for long-lasting performance.

Hot Melt & Reverse Sewing

Features airtight methods like hot melt and reverse sewing, preventing leaks and ensuring efficient filtration.

Features

Our liquid filtration bags.also known as filter sacks. are designed with precision, offering 1 micron filtration for fine liquid purification. Available in various sizes, including small size options, these bags cater to diverse industrial needs. Constructed from industrial-grade materials like PE, PP, and NMO, they ensure durability and longevity. The bags feature airtight methods such as hot melt and reverse sewing, preventing any leakage during filtration.

Benefits

By choosing our liquid filtration bags or filter sacks, industries can achieve superior liquid purity, reducing contamination risks and enhancing product quality. The customizable sizes ensure a perfect fit for any system, improving filtration efficiency. The industrial-grade materials guarantee long-lasting performance, even in harsh environments, reducing the need for frequent replacements. The airtight methods prevent leaks, ensuring efficient and uninterrupted filtration processes.

Use Cases

Our liquid filtration bags are ideal for a wide range of industrial applications, including chemical processing, pharmaceutical manufacturing, food and beverage production, and water treatment. In chemical processing, they remove impurities from solvents and reagents, ensuring product purity. In pharmaceuticals, they purify liquids used in drug production, meeting stringent quality standards. For food and beverage, they filter out contaminants from ingredients and final products, ensuring safety and taste. In water treatment, they remove particles and pollutants from water sources, providing clean and safe water for various uses.

|

Item

|

Dia(inch)

|

length(inch)

|

mm

|

|

1#

|

7″

|

17″

|

180X420

|

|

2#

|

7″

|

32″

|

180X810

|

|

3#

|

4″

|

9″

|

102X230

|

|

4#

|

4″

|

15″

|

102X410

|

|

5#

|

6″

|

22″

|

152×559

|

|

Material

|

PE,PP,NMO

|

|

Bag top ring

|

Plastic ring, Stainless steel ring

|

|

Relative filtration pore size

|

0.5, 1,5, 10, 25, 50, 100, 200 ,300µm

|

|

Type

|

various specifications

|

|

Airtight method:

|

Hot Melt, reverse sewing

|

|

Effective filtration area

|

various specifications

|

|

Others

|

special requirement of diameter and collar extension can be customized

|

Why Choose Our Liquid Filtration Bags?

Our liquid filtration bags offer 1 micron precision, ensuring ultra-fine filtration for superior liquid purity. Customizable sizes fit various systems, and industrial-grade materials guarantee durability in harsh environments.

How Do Our Bags Enhance Filtration Efficiency?

The airtight methods like hot melt and reverse sewing prevent leaks, ensuring efficient and uninterrupted filtration. This reduces downtime and maintenance costs, improving overall productivity.

What Industries Benefit from Our Filtration Bags?

Our bags cater to diverse industries, including chemical processing, pharmaceuticals, food and beverage, and water treatment. They remove impurities, ensuring product quality and safety across various applications.