Description

Providing reliable and efficient liquid filtration solutions to ensure product purity and process efficiency.

Food & Bev Producers – Pure Filtration, Superior Quality

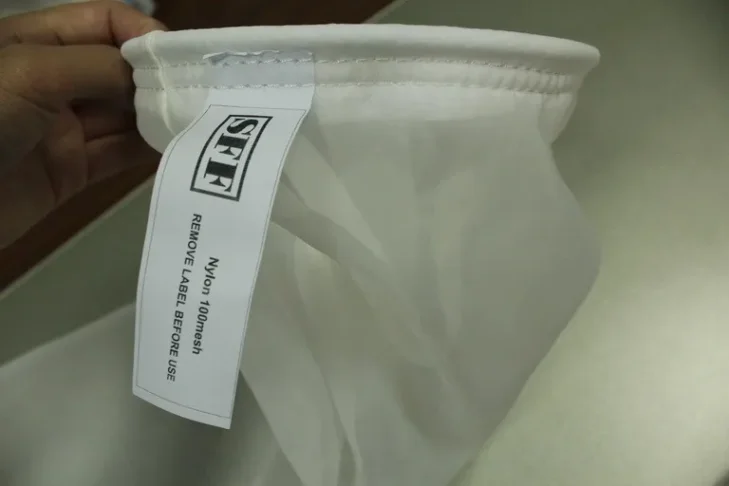

Industrial-Grade Material

Durable nylon mesh construction ensures long-lasting performance in harsh environments.

High Filtration Efficiency

Micro-range options from 25 to 1000 ensure precise filtration for various applications.

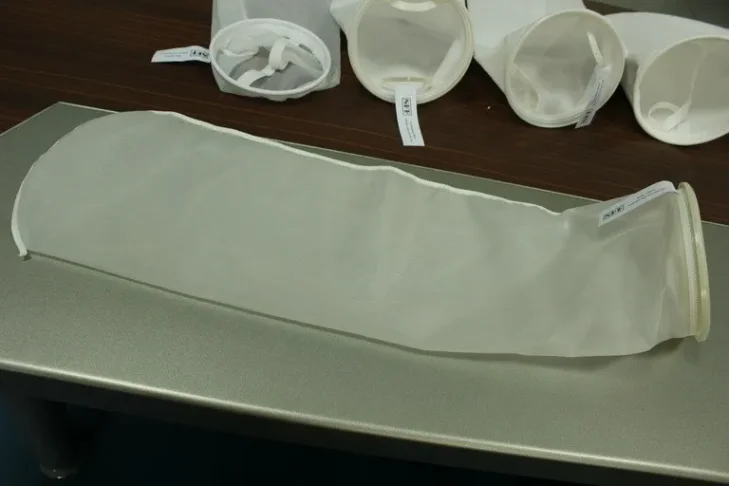

Versatile Size Options

Multiple sizes available to fit different filtration systems and requirements.

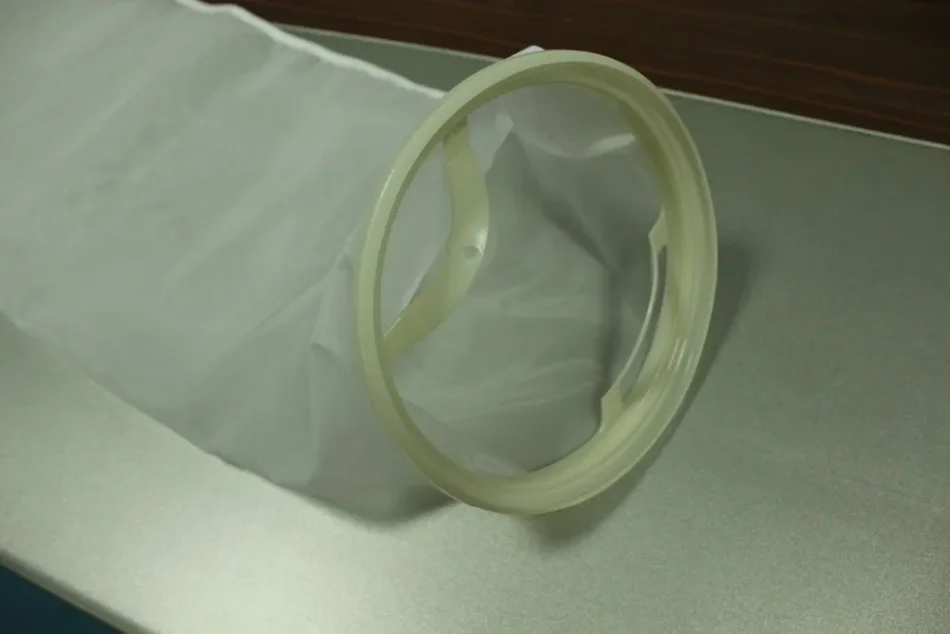

Easy-to-Use Drawstring Design

Simplifies installation and removal, saving time and labor costs.

Features

Our liquid filtration bags are crafted from premium nylon mesh, offering exceptional durability and chemical resistance. Available in a wide micro-range (25-1000), these bags cater to diverse filtration needs. The drawstring closure ensures a secure fit, while multiple size options (4×9″ to 7×32″) provide versatility. Manufactured using imported French and German machinery, our bags guarantee consistent quality.

Benefits

Experience enhanced process efficiency with our high-quality liquid filtration bags. The durable nylon construction reduces replacement frequency, lowering long-term costs. Precise micro-range filtration improves product purity, meeting stringent industry standards. Easy installation and removal minimize downtime, boosting overall productivity. Our industrial-grade bags withstand harsh operating conditions, ensuring reliable performance.

Use Cases

Ideal for the food and beverage industry, our liquid filtration bags effectively remove contaminants from liquids, ensuring product safety and quality. These industrial-grade bags also serve the fine chemical, petrochemical, pharmaceutical, and automotive manufacturing sectors. Their high-temperature resistance makes them suitable for water treatment applications. Small size options cater to specialized filtration needs in laboratories and pilot plants.

|

Name

|

nylon mesh filter bag

|

|

No

|

NMO

|

|

material

|

nylon

|

|

structure

|

monofil

|

|

micro range for nylon

|

25,50,75,100,120,150,200,250,300,400,500,600,800,1000

|

|

sewing types

|

sewing

|

|

filter method

|

surface

|

|

working temperature

|

160 degree celsius

|

|

Size 1

|

20 maxflow, 0.25filter area, 7*17inch, 180*420mm

|

|

Size 2

|

40 maxflow, 0.5filter area. 7*32inch, 180*810mm

|

|

Size 3

|

6 maxflow, 0.09filter area, 4*9inch, 102*230mm

|

|

Size 4

|

12 maxflow, 0.16filter area, 4*15inch, 102*410mm

|

|

Size 5

|

18 maxflow, 0.2filter area, 6*22inch, 152*559mm

|

|

Ring material

|

Galvanized/stainless steel ring/ H/F plastic ring

|

|

applicable industry

|

food and liquid drink field, fine chemical industry,

petro and chemical industry, phamaceutical and biological engineering, automobile manufacturing, water treatment |

|

Our advantages

|

1, 6 production lines

2, 18-year experience 3, imported machines from France and Germany, including NSC, ERKO. 4,prompt reply within 24 hours

5, sincere,serious, responsible and professional services

6, small order is accepted

|

|

Categories

|

Dust filtration for all kinds of dust filter bag and filter felt liquid filter filtration for all kinds of liquid filter bag and micro filte felt and nylon related machines for making different filter bags |

||||

|

Dust filtration

filter bag

|

Polyester filter bag

Polypropylene filter bag

Nomex dust filter bag ( nomex scrim or fiber glass scrim)

Pps dust filter bag

P84 dust filter bag

Ptfe dust filter bag

FMS dust filter bag

fiber glass filter bag

and so on

|

||||

|

Liquid filtration

|

Micro Polyester filter bag Micro PP filter bag Nylon Mesh filter bag Nomex liquid filter bag Ptfe liquid filter bag Filter cartridge Filter Housing and so on |

||||

|

Machines for dust filtration

|

Automatic filter bag tube line,Semi-Automatic filter bag tube line,Tripe-needle filter bag sewing machine,double need sewing machine, long arm sewing machine,overlock sewing machine,slitting machine,filter bag bottom punching machine,package machines,needle punch line and so on.

|

||||

|

Usagae/Occasion

|

– Biomass power stations

– Chemical and pharmaceutical industry – High temperature dedusting – Coal-fired power stations – Food industry – Non-ferrous metal and steel production – Cement, gypsum and lime industry – Thermal waste treatment |

||||

|

About us

|

1.Trade Assrurance, with trade assurance,you’ll enjoy: 100% product quality protection

100% on-time shipmeng protection

100% payment protection for your covered amount

2.Gold supplier

3.We accept transactions via alibaba.com

4.Payment protection

5.on-time shipment

6.wholesale low MOQS

7.Popular Buying requests for”filter bag”and “Nut milk bag”

|

||||

|

Size and Design

|

Any size is avaiable, we will follow you size and design

|

||||

|

MOQ(small order accept)

|

50pcs is also accept

|

||||

|

Price

|

We are factory(You are warmly welcome to pay a visit to our factory)

|

||||

|

Delivery time

|

Samples: finish 1-2 days, 2000pcs filter bags 7-15days, bulk orders depengd on your quantity.

|

||||

|

Package Detail

|

Standard Package:paper carton with plastic bag inside, some time with pallets.

|

||||

|

Warm Tips

|

More products details,our advantage,package detail,delivery time, samples and so on

|

||||

Why Choose Our Liquid Filtration Bags?

Our bags offer superior filtration performance with durable nylon construction. Available in various sizes and micro-ranges, they cater to diverse industrial applications. The drawstring design simplifies installation, while imported machinery ensures consistent quality.

How Do Our Bags Benefit Your Process?

By providing precise filtration, our bags enhance product purity and process efficiency. Their durability reduces replacement frequency, lowering operational costs. Easy handling minimizes downtime during bag changes.

What Makes Our Bags Stand Out?

We combine 18 years of experience with advanced French and German manufacturing technology. Our comprehensive quality control ensures every bag meets strict standards. We offer small order acceptance and prompt 24-hour replies.