Description

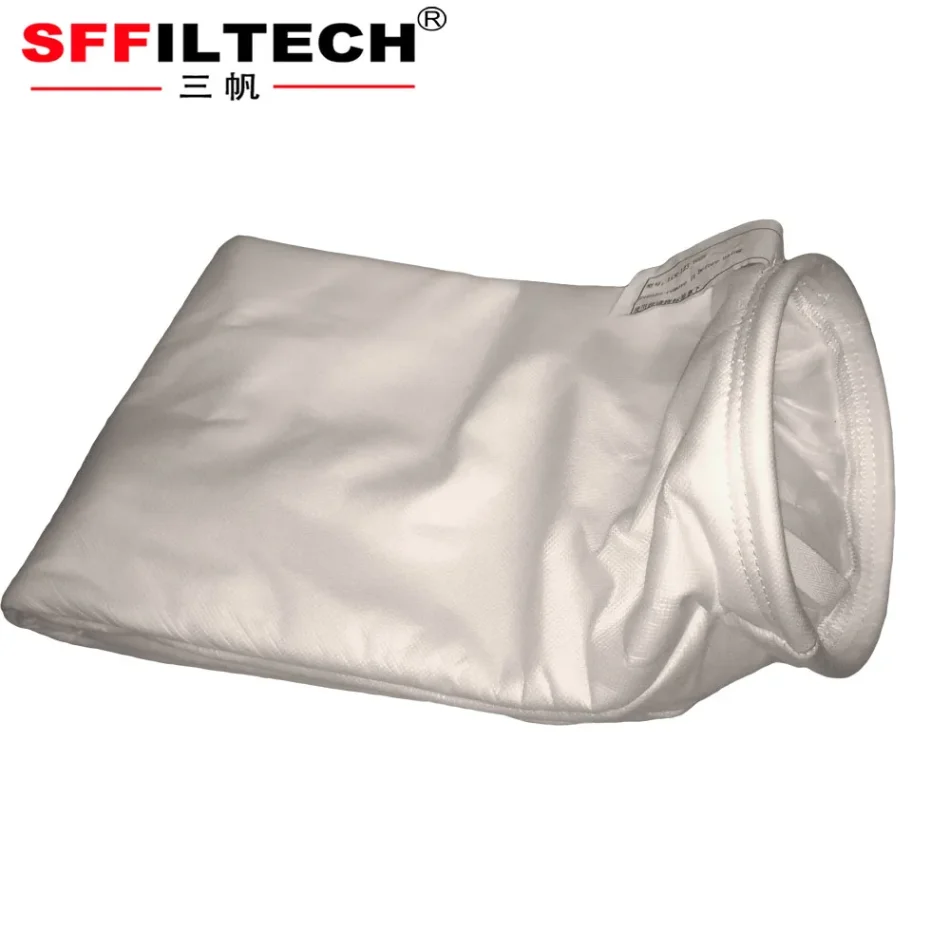

Our liquid filtration bags offer superior filtration efficiency, durability, and customization to meet the unique needs of various industries, ensuring clean and safe liquid processing.

Industries-Purify Liquids with Precision

High-Quality Materials

PE, PP, and Nylon construction ensure excellent chemical resistance and longevity.

Customizable Specifications

Tailor-made sizes, shapes, and filtration pore sizes to fit specific applications.

Versatile Applications

Ideal for chemical, food and beverage, paint, wastewater treatment, and more.

Industrial-Grade Performance

Robust design handles high flow rates and pressures, ensuring reliable filtration.

Features

Our liquid filtration bags are crafted from premium materials such as PE, PP, and Nylon, offering exceptional chemical resistance and durability. Available in a variety of sizes and shapes, these bags can be customized to meet specific filtration requirements. The 75-micron pore size ensures efficient removal of contaminants, while the plastic or stainless steel top rings provide secure attachment.

Benefits

By choosing our high-quality liquid filtration bags, customers benefit from enhanced filtration efficiency, reduced downtime, and lower maintenance costs. The customizable nature of our bags allows for optimal performance in diverse applications, ensuring clean and safe liquid processing. Additionally, the industrial-grade construction guarantees long-lasting performance, even in harsh environments.

Use Cases

Our liquid filtration bags are widely used in the chemical industry for filtering solvents, acids, and bases. In the food and beverage sector, they ensure the purity of beverages, dairy products, and edible oils. The paint and lacquer industry relies on our bags for removing impurities from coatings, while wastewater treatment plants use them for effective sludge removal. Furthermore, our bags find applications in the adhesive industry for filtering resins and glues.

| Item | Dia(inch) | length(inch) | mm |

| 1# | 7″ | 17″ | 180X420 |

| 2# | 7″ | 32″ | 180X810 |

| 3# | 4″ | 9″ | 102X230 |

| 4# | 4″ | 15″ | 102X410 |

| 5# | 6″ | 22″ | 152×559 |

| Material | PE,PP,NMO |

| Bag top ring | Plastic ring , Stainless steel ring |

| Relative filtration pore size | 0.2,0.5, 1,5, 10, 25, 50, 100, 200 ,300…1000µm |

| Type | various specifications |

| Airtight method: | weld, reverse sewn, outside sewn |

| Effective filtration area | various specifications |

| Others | special requirement of diameter and collar extension can be customized |

Why Choose Our Liquid Filtration Bags?

Our liquid filtration bags stand out for their superior quality, customization options, and versatility. Crafted from premium materials, they offer exceptional chemical resistance and durability, ensuring reliable performance in various industries.

How Do Our Bags Benefit Your Industry?

By choosing our liquid filtration bags, you benefit from enhanced filtration efficiency, reduced downtime, and lower maintenance costs. The customizable nature of our bags allows for optimal performance in your specific application, ensuring clean and safe liquid processing.

What Sets Our Bags Apart from Competitors?

Our liquid filtration bags are designed with industrial-grade performance in mind. They can handle high flow rates and pressures, making them ideal for demanding environments. Additionally, our commitment to customization ensures that you get the perfect bag for your needs.