Description

Our liquid filtration bags provide high-quality, precise, and customizable filtration solutions to meet the unique needs of various industrial applications.

Industries-Enhance Filtration with Custom Bags

High-Quality Materials

PE, PP, and NMO materials ensure durability and chemical resistance, extending the lifespan of the bags.

Customizable Specifications

Diameter, length, and pore size can be tailored to meet specific filtration requirements, offering flexibility.

Precision Filtration

With pore sizes ranging from 0.5 to 300 microns, our bags provide fine and accurate filtration for various liquids.

Industrial-Grade Construction

Designed to withstand harsh industrial environments, ensuring reliable performance and minimal downtime.

Features

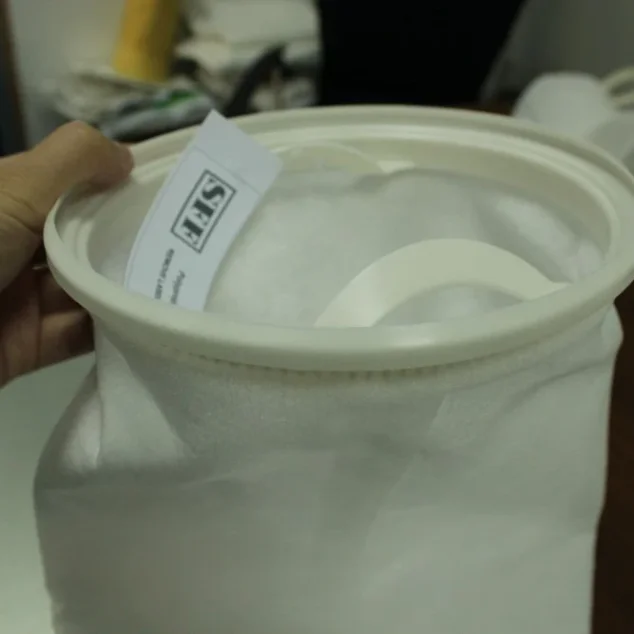

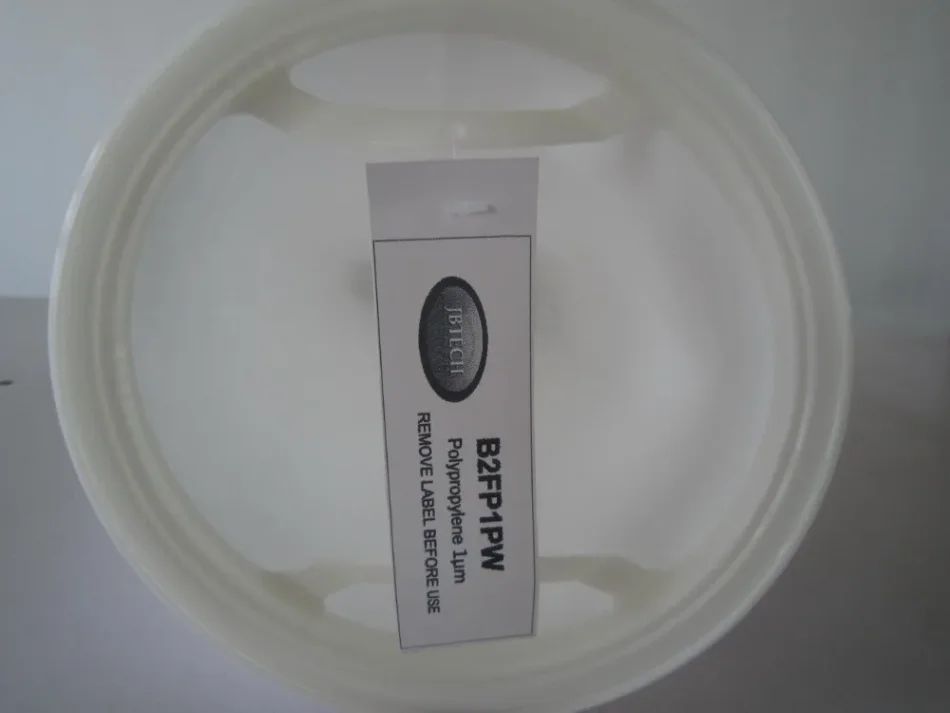

Our liquid filtration bags are crafted from high-quality materials such as PE, PP, and NMO, offering exceptional durability and chemical resistance. Available in a range of sizes, from 4 to 7 inches in diameter and 9 to 32 inches in length, these bags cater to diverse filtration needs. The pore size can be customized from 0.5 to 300 microns, providing precise control over the filtration process. The bags feature a plastic or stainless steel ring at the top for easy installation and secure sealing.

Benefits

By choosing our liquid filtration bags, customers benefit from enhanced filtration efficiency, reduced downtime, and lower maintenance costs. The customizable specifications ensure that the bags perfectly fit the existing filtration systems, optimizing performance. The high-quality materials and industrial-grade construction guarantee long-lasting use, even in demanding environments, providing a cost-effective solution for businesses.

Use Cases

Our liquid filtration bags find applications in a wide range of industries, including chemical processing, food and beverage manufacturing, pharmaceuticals, and water treatment. In chemical processing, they effectively remove impurities from liquids, ensuring product purity. In the food and beverage industry, they play a crucial role in maintaining hygiene standards by filtering out contaminants. Pharmaceutical companies rely on our bags for precise filtration during drug production, while water treatment plants use them to purify water for various uses.

|

Item

|

Dia(inch)

|

length(inch)

|

mm

|

|

1#

|

7″

|

17″

|

180X420

|

|

2#

|

7″

|

32″

|

180X810

|

|

3#

|

4″

|

9″

|

102X230

|

|

4#

|

4″

|

15″

|

102X410

|

|

5#

|

6″

|

22″

|

152×559

|

|

Material

|

PE,PP,NMO

|

|

Bag top ring

|

Plastic ring, Stainless steel ring

|

|

Relative filtration pore size

|

0.5, 1,5, 10, 25, 50, 100, 200 ,300µm

|

|

Type

|

various specifications

|

|

Airtight method:

|

Hot Melt, reverse sewing

|

|

Effective filtration area

|

various specifications

|

|

Others

|

special requirement of diameter and collar extension can be customized

|

Why Choose Our Liquid Filtration Bags?

Our liquid filtration bags stand out due to their high-quality materials, customizable specifications, and precision filtration capabilities. They are designed to meet the unique needs of various industries, providing reliable and efficient filtration solutions.

How Do Our Bags Benefit Your Business?

By using our liquid filtration bags, businesses can enhance filtration efficiency, reduce downtime, and lower maintenance costs. The customizable features ensure a perfect fit for existing systems, optimizing performance and saving time and resources.

What Industries Can Benefit from Our Bags?

Our liquid filtration bags are suitable for a wide range of industries, including chemical processing, food and beverage manufacturing, pharmaceuticals, and water treatment. They effectively remove impurities, maintain hygiene standards, and ensure product purity in various applications.