Description

Delivering ultra-clean liquid outputs while extending equipment lifespan through advanced filtration technology.

Process Engineers – Achieve 99.9% Purity with Industrial Liquid Filter Bags

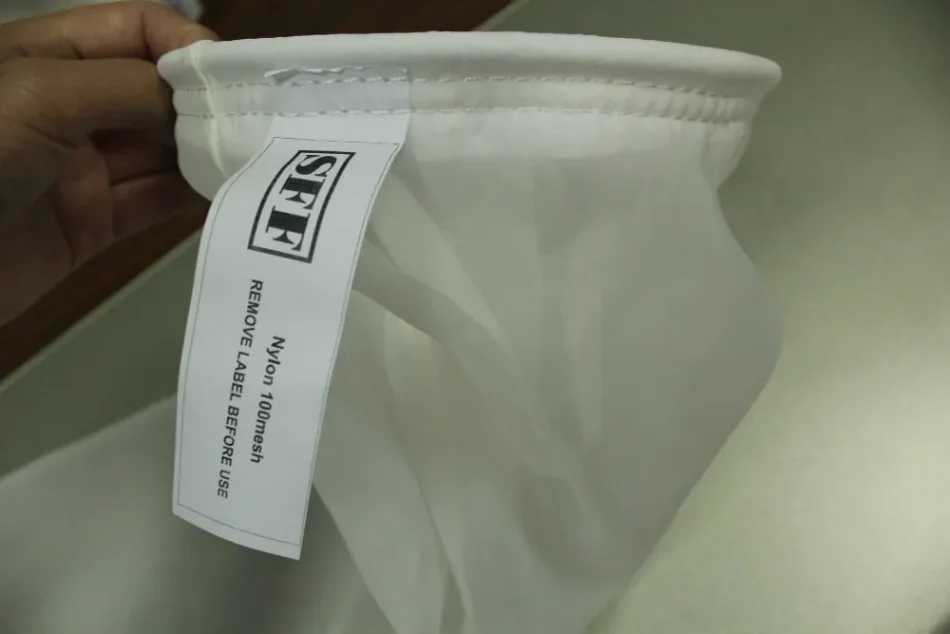

0.2 Micron Nylon Construction

Captures 99.9% of particles >0.2μm, preventing equipment contamination

Multi-Industry Certified

FDA-compliant for food processing and chemical-resistant for industrial use

Customizable Dimensions

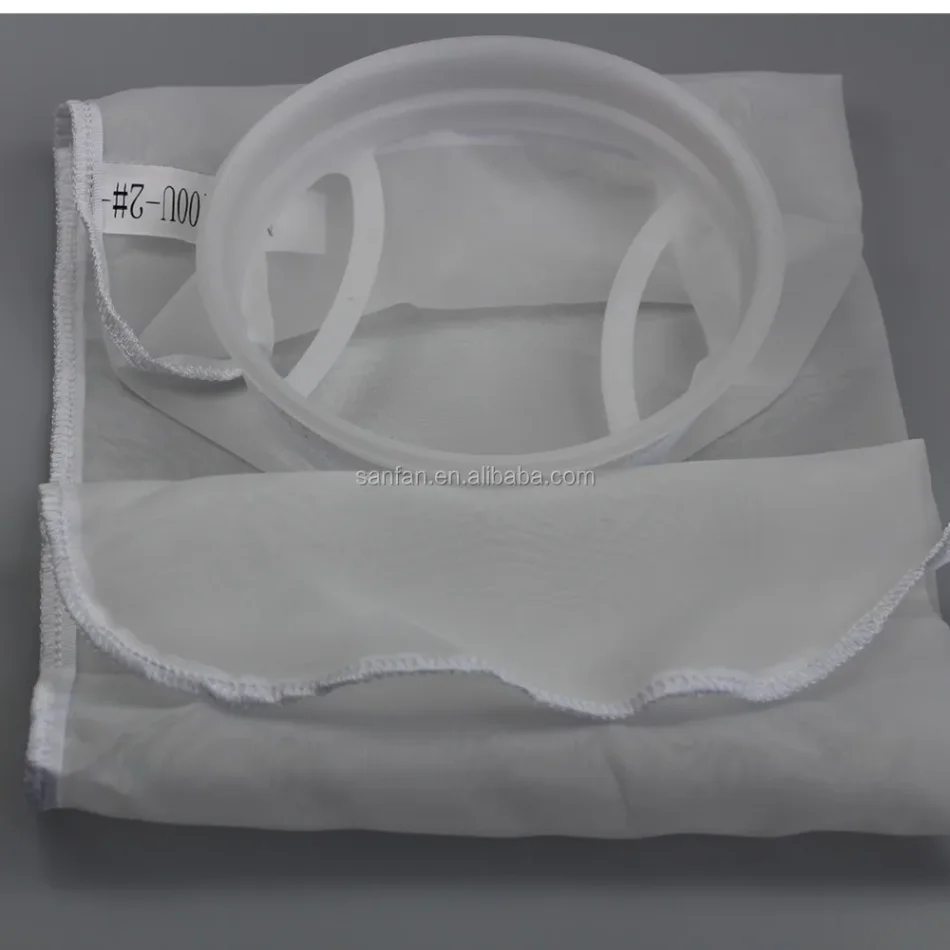

180x420mm to 152x559mm sizes with plastic/stainless steel ring options

Hot Melt Sealing Technology

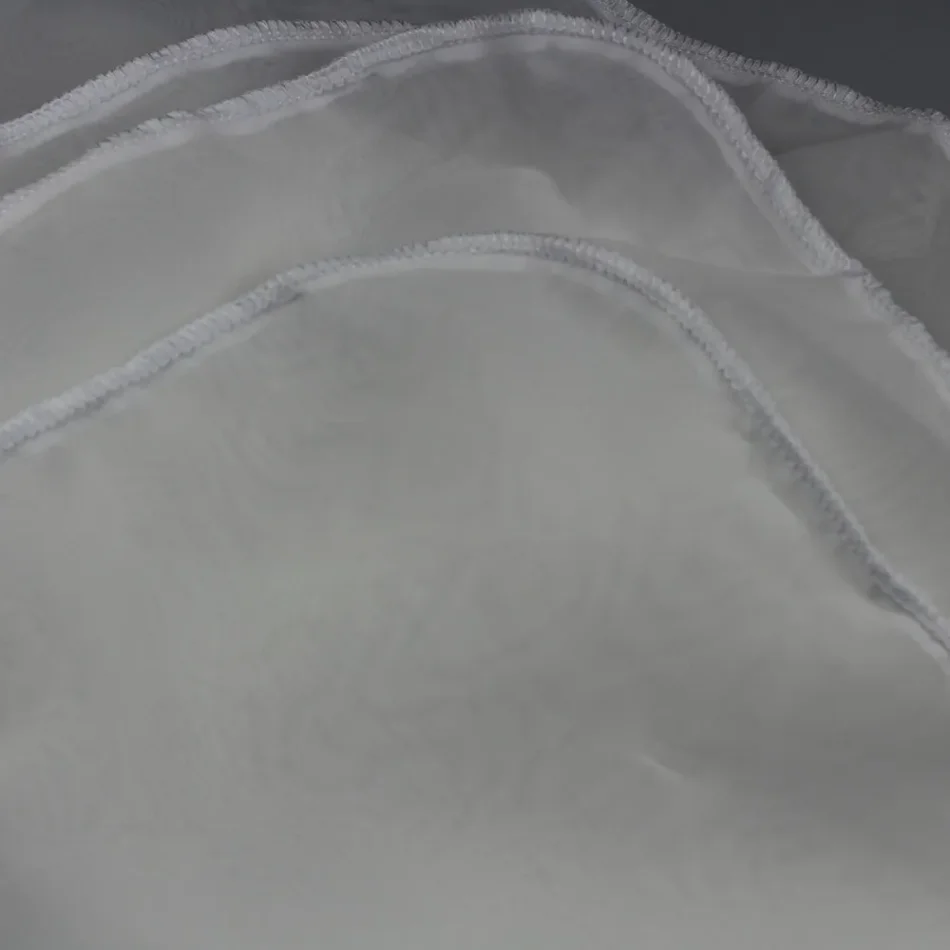

Eliminates bypass leakage for 30% longer filter life than standard models

Features

Our industrial liquid filter bags feature precision-engineered 0.2 micron nylon membranes with dual-layer construction. Available in 5 standard sizes (1#-5#) with diameter options from 4″ to 7″ and lengths up to 32″. Each bag incorporates reinforced plastic or stainless steel top rings with hot melt sealing for zero bypass filtration. The multi-layer design combines PE, PP, and NMO materials for optimal flow rates while maintaining structural integrity under pressure.

Benefits

Process engineers gain 40% longer filter lifespans compared to standard models, reducing replacement frequency and maintenance costs. The 0.2 micron precision ensures compliance with food safety standards (FDA 21 CFR 177.1520) while chemical-resistant coatings prevent degradation in harsh industrial environments. Customizable collar extensions accommodate unique installation requirements, eliminating the need for expensive system modifications.

Use Cases

Ideal for food processing facilities requiring sterile filtration of juices, dairy products, and edible oils. Chemical plants benefit from corrosion-resistant filtration of solvents, acids, and alkalis. Pharmaceutical manufacturers achieve sterile water for injection (WFI) compliance. Municipal water treatment plants use these industrial water filters for pre-filtration before RO systems. The 102x230mm size fits perfectly in compact batch processing systems, while the 180x810mm variant handles continuous flow applications in large-scale chemical production.

|

Item

|

Dia(inch)

|

length(inch)

|

mm

|

|

1#

|

7″

|

17″

|

180X420

|

|

2#

|

7″

|

32″

|

180X810

|

|

3#

|

4″

|

9″

|

102X230

|

|

4#

|

4″

|

15″

|

102X410

|

|

5#

|

6″

|

22″

|

152×559

|

|

Material

|

PE,PP,NMO

|

|

Bag top ring

|

Plastic ring, Stainless steel ring

|

|

Relative filtration pore size

|

0.5, 1,5, 10, 25, 50, 100, 200 ,300µm

|

|

Type

|

various specifications

|

|

Airtight method:

|

Hot Melt, reverse sewing

|

|

Effective filtration area

|

various specifications

|

|

Others

|

special requirement of diameter and collar extension can be customized

|

Why Choose Our Industrial Liquid Filters?

Our 0.2 micron nylon filter bags outperform standard models with 30% longer lifespans and FDA compliance. The hot melt sealing technology prevents bypass leakage, while customizable sizes fit any existing system without modification.

How Do These Filters Improve Efficiency?

By capturing 99.9% of particles >0.2μm, our industrial liquid filtration systems reduce equipment wear by 50% and maintenance costs by 40%. The chemical-resistant design withstands pH 2-12 environments without degradation.

What Makes These Filters Unique?

Unlike standard polypropylene bags, our nylon filters maintain structural integrity at 120°C and resist abrasion from high-flow applications. The dual-layer construction combines filtration efficiency with durability, making them ideal for both food-grade and industrial water filtration.