Description

Our industrial liquid filters deliver unparalleled filtration efficiency, reducing contaminants and ensuring product purity across industries.

Industries – Purify Liquids Efficiently

Multi-Material Compatibility

Supports PP, PE, and Nylon bags for versatile filtration needs.

Wide Micron Range

Offers filtration from 0.5 to 800 microns, catering to precise requirements.

High Temperature Resistance

Withstands continuous temperatures up to 90°C and peak temperatures of 95°C.

Chemical Resistant

Excellent resistance to acids, alkalis, and hydrolysis for long-lasting performance.

Features

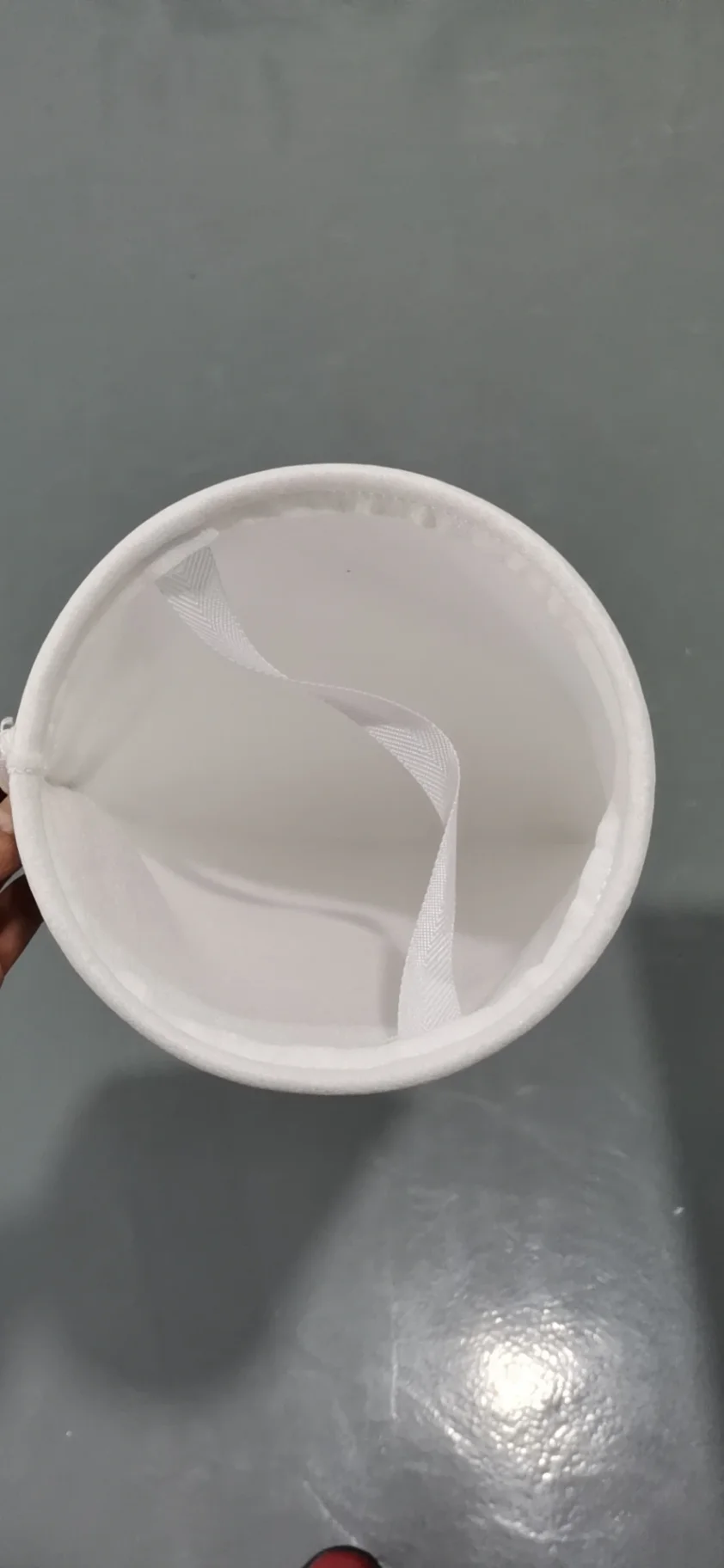

Our liquid filtration bags, also known as filter sacks are crafted from premium materials like PP, PE, and Nylon, ensuring robust filtration. They feature a wide range of micron ratings (0.5 to 800 microns) to meet diverse filtration needs. The bags are designed to withstand high temperatures (continuous up to 90°C, peak up to 95°C) and exhibit excellent resistance to chemicals, ensuring durability and reliability.

Benefits

By choosing our industrial liquid filters, customers benefit from enhanced filtration efficiency, leading to purer products and reduced downtime. The wide micron range allows for precise control over filtration, catering to specific industry requirements. The high temperature and chemical resistance ensure longevity, reducing the need for frequent replacements and lowering operational costs.

Use Cases

Our industrial liquid filter bags are ideal for a variety of industries, including cement production, chemical processing, food and beverage manufacturing, and wastewater treatment. In cement plants, they effectively remove particulates from process liquids, ensuring product quality. Chemical industries rely on them for filtering corrosive liquids, while food processors use them to maintain hygiene standards. Wastewater treatment facilities benefit from their ability to handle large volumes of contaminated water efficiently.

|

Item

|

Polyproplene filter felt

|

|

Construction

|

Needle felt

|

|

Fibre Composition

|

Polyproplene or nylon

|

|

Micro rating

|

1um 5um 10um 25um 50um 75um 100um 125um 150um 200um 250um 300um

|

|

Continuous Temperature

|

90℃

|

|

Peak Temperature

|

95℃

|

|

Resistance Hydrolysis

|

Excellent

|

|

Resistance to Acids

|

Excellent

|

|

Resistance to Alkalis

|

Excellent

|

|

Resistance to Oxidation

|

Restrict

|

|

PHvalue

|

1-14

|

|

Application

|

Application to food ,flour.sugar,fertilizer,electropating and pesticide industries

|

|

Remark

|

Restrict resistance to oxidation,but excellent resistance to hydrolysis

|

|

Item

|

Dia(inch)

|

length

|

mm

|

|

1#

|

7″

|

17″

|

180X420

|

|

2#

|

7″

|

32″

|

180X810

|

|

3#

|

4″

|

9″

|

102X230

|

|

4#

|

4″

|

15″

|

102X410

|

|

5#

|

6″

|

22″

|

152×559

|

|

Material

|

PE,PP,NMO

|

|

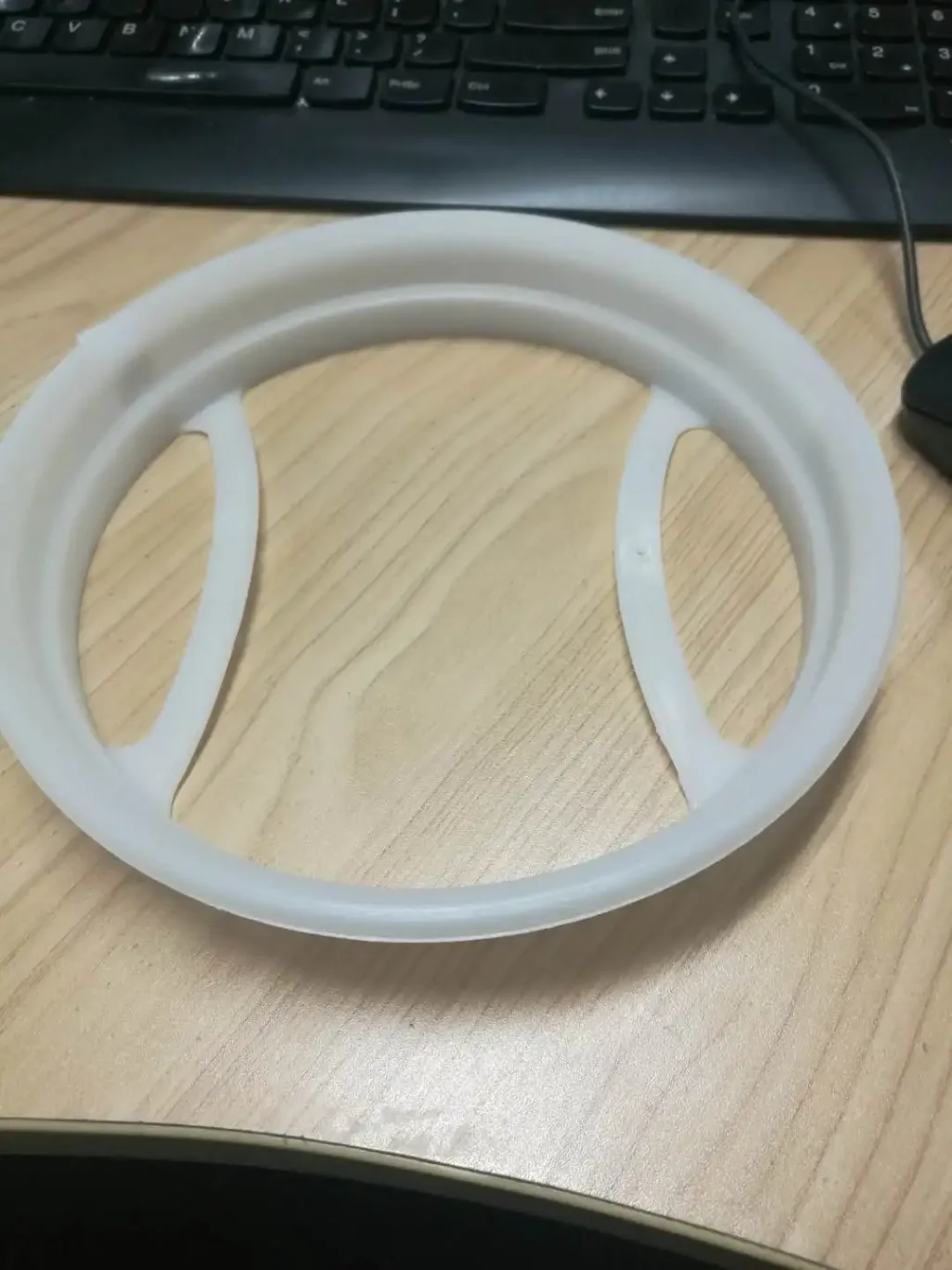

Bag top ring

|

Plastic ring, Stainless steel ring

|

|

Relative filtration pore size

|

0.5, 1,5, 10, 25, 50, 100, 200 ,300µm,500um,800um

|

|

Type

|

various specifications

|

|

Airtight method:

|

Hot Melt, reverse sewing

|

|

Effective filtration area

|

various specifications

|

|

Others

|

special requirement of diameterand collar extension can becustomized

|

|

Catalogue

|

Dust filtration,liquid filter filtration and related machines

|

||

|

Dust filtration

filter bag

|

Polyester filter bag,polyester antistatic filter bag,polyester filter bag blending,polyester filter bag with membrane,polyester filter bag water and oil repellent,polyester filter bagspecial type,pp filter bag,aramid filter bag pps filter bag acrylic filter bag, p84 filter bag, ptfe filter bag,ptfe mix p84filter bag,HST filter bag,fiberglass filter bag,PTFE mix pps filter bag,Basalt filter bag,

|

||

|

Liquid filtration filter bag

|

Polyester filter bag, PE filter bag, Micro filter bag,5 micro filter bag,10 micro filter bags,PP filter bag,nylon filter bag,ptfe filter bag,stainsteel filter bag and so on.

|

||

|

Machines for making dust filter bags

|

Automatic filter bag tube line,Semi-Automatic filter bag tube line,Tripe-needle filter bag sewing machine,double need sewing machine, long arm sewing machine,overlock sewing machine,slitting machine,filter bag bottom punching machine,package machines,needle punch line and so on.

|

||

|

Usagae/Occasion

|

– Biomass power stations

– Chemical industry – High temperature dedusting – Coal-fired power stations – Food industry – Non-ferrous metal and steel production – Cement, gypsum and lime industry – Thermal waste treatment |

||

|

Categories

|

Dust filtration for all kinds ofdust filter bag and filter felt liquid filter filtration for all kinds ofliquid filter bag and micro filte felt and nylon related machines for making different filter bags |

||

|

Dust filtration

filter bag

|

Polyester filter bag

Polypropylene filter bag

Nomex dust filter bag ( nomex scrim or fiber glass scrim)

Pps dust filter bag

P84 dust filter bag

Ptfe dust filter bag

FMS dust filter bag

fiber glass filter bag

and so on

|

||

|

Liquid filtration

|

Micro Polyester filter bag Micro PP filter bag Nylon Mesh filter bag Nomex liquid filter bag Ptfe liquid filter bag Filter cartridge Filter Housing and so on |

||

|

Machines for dust filtration

|

Automatic filter bag tube line,Semi-Automatic filter bag tube line,Tripe-needle filter bag sewing machine,double need sewing machine, long arm sewing machine,overlock sewing machine,slitting machine,filter bag bottom punching machine,package machines,needle punch line and so on.

|

||

|

Usagae/Occasion

|

– Biomass power stations

– Chemical industry – High temperature dedusting – Coal-fired power stations – Food industry – Non-ferrous metal and steel production – Cement, gypsum and lime industry – Thermal waste treatment |

||

|

About us

|

1.Trade Assrurance, with trade assurance,you’ll enjoy: 100% product quality protection 100% on-time shipmeng protection

100% payment protection for your covered amount

2.Gold supplier

3.We accept transactions via alibaba.com

4.Payment protection

5.on-time shipment

6.wholesale low MOQ

7.Popular Buying requests for”filter bag”and “Nut milk bag”

|

||

|

Size and Design

|

Any size is avaiable, we will follow you size and design

|

||

|

MOQ(small order accept)

|

50pcs is also accept

|

||

|

Price

|

We are factory(You are warmly welcome to pay a visit to our factory)

|

||

|

Delivery time

|

Samples: finish 1-2 days, 2000pcs filter bags 7-15days, bulk orders depengd on your quantity.

|

||

|

Package Detail

|

Standard Package:paper carton with plastic bag inside, some time with pallets.

|

||

|

Warm Tips

|

More products details,our advantage,package detail,delivery time, samples and so on

|

||

Why Choose Our Industrial Liquid Filters?

Our industrial liquid filters stand out for their multi-material compatibility, wide micron range, and high temperature resistance. They are designed to meet the specific needs of various industries, ensuring efficient and reliable filtration.

How Do Our Filters Benefit Your Industry?

By providing precise filtration control, our filters enhance product quality, reduce downtime, and lower operational costs. Their durability and chemical resistance ensure long-lasting performance, making them a cost-effective choice for your business.

What Sets Our Filters Apart from Competitors?

Our industrial liquid filters are engineered with advanced materials and technology, offering superior filtration efficiency and reliability. We provide customized solutions to meet your unique requirements, ensuring optimal performance in your specific industry.