Description

Delivering exceptional filtration performance and durability to optimize industrial processes.

Industries – Achieve Peak Efficiency with Our Filter Bags

High-Efficiency Filtration

Captures tiny particles with precision, ensuring a clean production environment.

Durable Construction

Resistant to abrasion and chemicals, extending lifespan and reducing replacement frequency.

Customizable Design

Tailored to specific filtration needs, accommodating various customer requirements.

Cost-Effective Solution

Provides a budget-friendly option without compromising on quality or performance.

Features

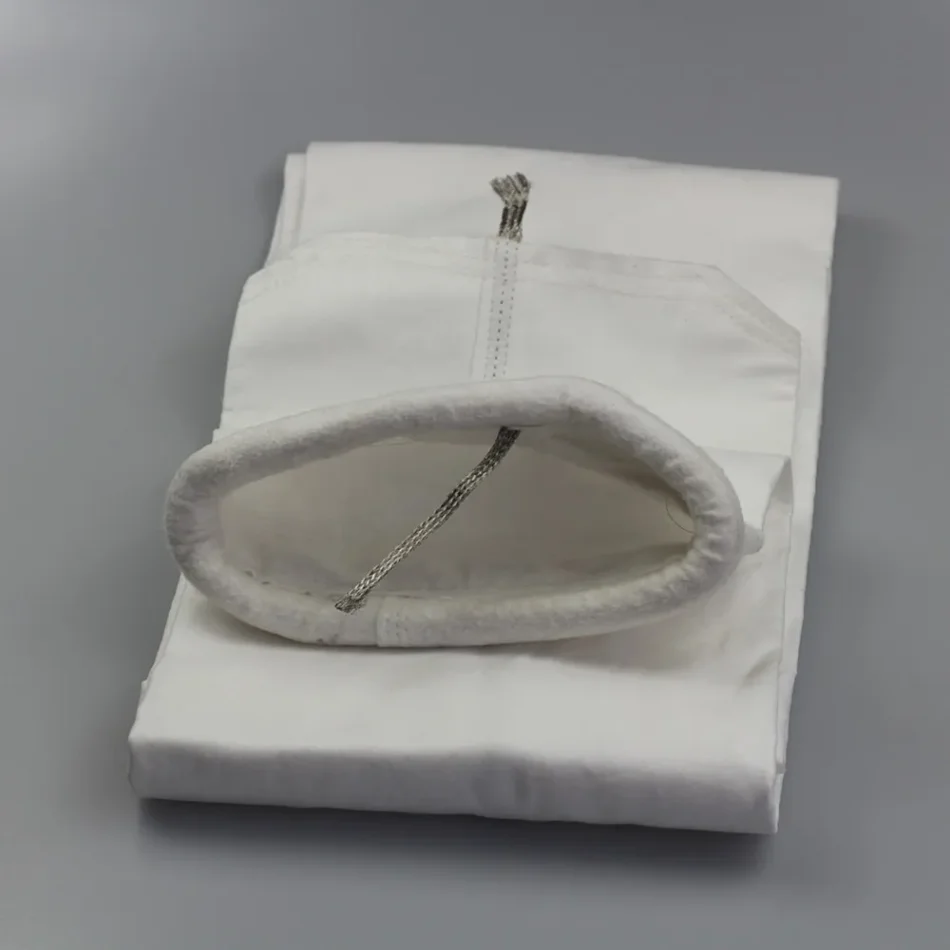

Our industrial filter bags are crafted from 100% filament polyester fiber, ensuring high filtration performance. Available in various shapes and sizes, they are designed to fit different filtration systems. The bags undergo a rigorous manufacturing process, including needling, singeing, heat setting, and rolling, to produce polyester felt with exceptional properties. Customization options for diameter, length, and weight are available to meet specific requirements.

Benefits

Experience the benefits of our industrial filter bags, including effective filtration performance, versatility in applications, stable physical properties under various working conditions, and ease of cleaning and maintenance. Their durability and resistance to abrasion and chemicals ensure a longer lifespan, reducing operational costs and downtime.

Use Cases

Our industrial filter bags are widely used in diverse industries such as cement production, steel manufacturing, power generation, chemical processing, food and beverage, mining, woodworking, textile, recycling, plastics, and automotive. They excel in dust collection systems, air pollution control equipment, and liquid filtration processes, ensuring a cleaner and safer working environment.

|

physical and mechanical properties of polyester filter bags

|

||

|

Item

|

Industry Polyester Dust Collector Filter Bag

|

|

|

Construction

|

Needle Polyester Felt

|

|

|

Fibre Composition

|

Polyester Fibre

|

|

|

Weight

|

350gsm, 400gsm, 450gsm, 500GSM, 550GSM, 600gsm or OEM/ODM

|

|

|

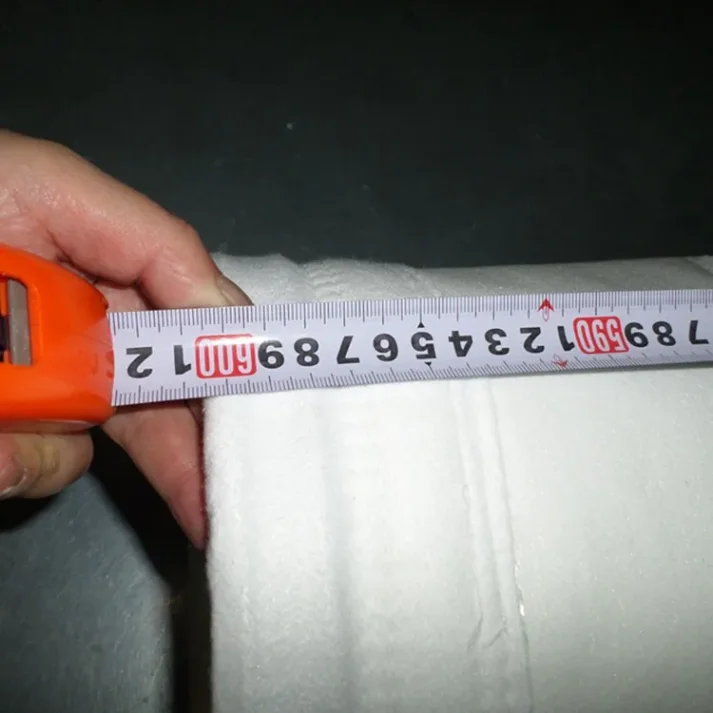

Thickness

|

1.8-1.9mm

|

|

|

Mean Air Permeability

|

10-15 m3/m2/min@12.7mmH2O

|

|

|

Breaking Strength-MD(warp)

|

900 N / 5cm

|

|

|

Breaking Strength-CMD(weft)

|

1300 N / 5cm

|

|

|

Breaking Elongation( N/5cm)-MD(warp)

|

20%

|

|

|

Breaking Elongation( N/5cm)-CMD(weft)

|

40%

|

|

|

Dry Shrinkage MD(130℃(warp)

|

<1.5 %

|

|

|

Dry Shrinkage CMD(130℃(weft)

|

<1.5 %

|

|

|

Continuous Temperature

|

<130 Degree

|

|

|

Recommended Maximum Surge

|

150 deg C

|

|

|

Normal Finishing

|

Singeing, Calendering, Heat set

|

|

|

Functional Finishing

|

anti-static, water and oil repellent, PTFE membrance

|

|

|

Feature

|

Good resistance to oxidation, limites resistance to acids and alkalis. Serve life will be affected by water content under high temperature.

|

|

|

Application

|

To mine, limestone, cement, iron and steel induestries, alumina delivery, electrolytic aluminium, non-ferrous metal production, wood processing, food processing industry.

|

|

|

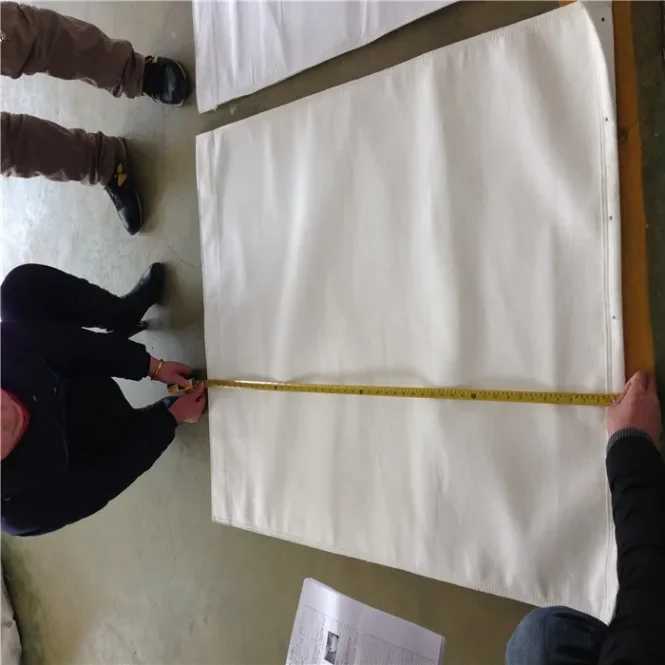

conventional size and weight parameters of polyester filter bags

|

||||

|

Diameter (mm)

|

Length (mm)

|

Weight (g/㎡)

|

||

|

120、130、133、155、180、200、250、292、300

|

1000、1500、2000、2400、25000、2480、2800、3000、3200、3600、4000、4400、5000、6000、8000

|

350, 400, 450, 500, 550, 600

|

||

|

Most commonly used dimensions

|

133mm*1500mm、133mm*2000mm、133mm*2500mm

|

|||

|

Most commonly used weight

|

450g, 500g

|

|||

|

We can customize diameter, length, and weight for you

|

||||

|

Classified according to polyester filter bag material and process

|

||

|

Standard Polyester Filter Bags:

|

This is the most common type of polyester filter bag, suitable for general industrial filtration needs. They exhibit excellent

high-temperature resistance and chemical stability. |

|

|

Antistatic Polyester Filter Bags

|

Specifically designed to prevent the accumulation of static electricity, these polyester filter bags are often used in explosive

environments or special applications where antistatic properties are required. |

|

|

Corrosion-Resistant Polyester Filter Bags

|

Featuring additional chemical corrosion resistance, these polyester filter bags are suitable for filtration operations in

corrosive environments. |

|

|

Water and Oil Repellent Polyester Filter Bags

|

Treated to repel water and oil, these polyester filter bags are ideal for applications involving the filtration of water and oil

mixtures. |

|

|

Micron Polyester Filter Bags

|

Characterized by small pore sizes, these filter bags are designed to capture tiny particles, making them suitable for applications

that require efficient fine filtration. |

|

|

P84/Polyester Blend Filter Bags

|

Combining P84, a high-temperature synthetic fiber, with polyester, these filter bags offer excellent high-temperature stability

and abrasion resistance, making them suitable for hot environments. |

|

|

Needle Felt Polyester Filter Bags

|

Manufactured using a needle felting process, these filter bags have high physical strength and abrasion resistance, making them

suitable for environments that demand durability. |

|

|

Acid-Resistant Polyester Filter Bags

|

With additional acid resistance, these polyester filter bags are suitable for filtration operations in acidic environments.

|

|

|

PTFE-Coated Polyester Filter Bags

|

Featuring a polytetrafluoroethylene (PTFE) coating, these polyester filter bags provide outstanding resistance to chemical

corrosion and easy-cleaning characteristics. |

|

|

Classify according to polyester filter bag shape or cleaning method

|

||

|

Bag-shaped Polyester Filter Bags

|

This is the most fundamental and common shape for polyester filter bags, typically either rectangular or cylindrical, secured

through various sealing methods. |

|

|

Round Bottom Polyester Filter Bags

|

These bags have a round-shaped bottom, suitable for specific filtration equipment and applications that require improved fluid

distribution. |

|

|

Flat Polyester Filter Bags

|

Flat polyester filter bags often have a larger filtration surface area, making them suitable for applications that demand high

throughput and low airflow velocity |

|

|

Conical Polyester Filter Bags

|

Featuring a conical bottom, these polyester filter bags are applicable in situations where better particle sedimentation and

discharge are required. |

|

|

Pleated Polyester Filter Bags

|

Designed with a pleated structure to increase the filtration surface area, these bags enhance filtration efficiency and are

suitable for applications with higher filtration performance requirements. |

|

|

Pulse jet polyester filter bags

|

Pulse jet filter bags are a type of filter bag used in pulse jet dust collection systems. This type of filter bag is a common

industrial filtration material typically employed in dust removal equipment such as pulse jet baghouse dust collectors. |

|

|

Reverse air polyester filter bags

|

Reverse air filter bags are a type of filter bag used in reverse air dust collection systems. Designed to handle high dust loads

and large particulate environments, these filter bags are commonly employed in reverse air baghouse dust collectors, which are widely used industrial dust removal equipment. |

|

|

Envelope filter bag

|

Envelope filter bag refers to a filter bag with a specific design, similar to the appearance and shape of an envelope.

|

|

|

Basic commercial terms of polyester filter bag

|

||

|

Place of Origin

|

Shanghai, China

|

|

|

Brand Name

|

SFFILTECH

|

|

|

Certification

|

ISO

|

|

|

Minimum Order Quantity

|

10pcs (1pcs free sample)

|

|

|

Packaging Details

|

The inner packing is in plastic bags The outer packing is in carton Large volume can also support custom packaging

|

|

|

Delivery Time

|

7-30days after deposit. According to the specific order quantity. 1-7days for sample

|

|

|

Port of shipment

|

Shanghai, Ningbo, Qingdao, Lianyungang, Guangzhou, Shenzhen or Others

|

|

|

Payment Terms

|

30% Deposit, balance TT on copy B/L. Other payment methods can be negotiated according to the order requirements

|

|

|

Supply Ability

|

100000pcs/month

|

|

|

OEM/ODM

|

Yes, we can support customized, like size, shape, material

|

|

|

After-sales Services

|

1 year warranty after we both sign the plant investigation usually for this one

|

|

Why Choose Our Industrial Filter Bags?

Our industrial filter bags offer unmatched filtration efficiency, durability, and customization options. Designed to meet the rigorous demands of various industries, they ensure a cleaner production environment and optimize industrial processes.

What Makes Our Filter Bags Stand Out?

Our filter bags are crafted from premium polyester fiber, undergoing a meticulous manufacturing process to ensure high performance. They are resistant to abrasion and chemicals, extending their lifespan and reducing replacement costs. Customization options cater to specific filtration needs.

Applications Across Industries

From cement and steel to food and beverage, our industrial filter bags are versatile and effective. They excel in dust collection, air pollution control, and liquid filtration, ensuring a safer and cleaner working environment across diverse industries.