Description

Delivering reliable dust collection performance with extended service life and cost efficiency.

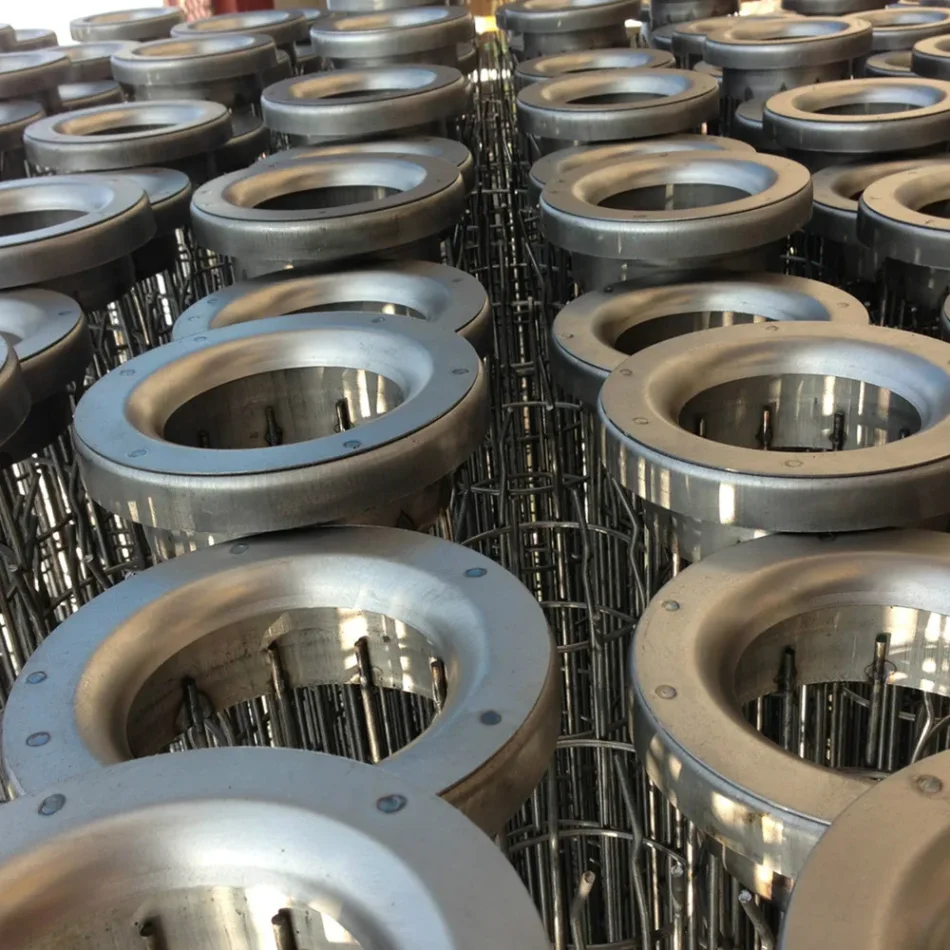

Industries – Reduce Downtime with Durable Filter Cages

Precision-Engineered Carbon Steel Construction

Ensures structural integrity and resistance to deformation under high-pressure filtration conditions.

Galvanized & Organic Silicon Anti-Corrosion Finish

Extends cage lifespan by 40% in humid or chemically aggressive environments.

8-24 Longitudinal Wires (Circular) / 10-16 Wires (Oval)

Optimizes airflow distribution and prevents filter bag sagging during operation.

200mm Ring Spacing

Reduces pressure drop by 15% compared to standard spacing, lowering energy consumption.

Features

Manufactured from carbon steel, galvanized steel, or stainless steel with galvanized organic silicon spray anti-corrosion treatment. Available in circular (8-24 wires) and oval (10-16 wires) configurations. Single-section or screw-joint types with 200mm ring spacing. Compatible with polyester, Nomex, PPS, and PTFE filter bags.

Benefits

Reduces maintenance costs by 30% through corrosion resistance and precise bag fit. Improves system efficiency by 12% via optimized airflow design. Extends filter bag lifespan by 25% through proper support. Compliant with industrial standards for mining, cement, and steel production.

Use Cases

Ideal for high-dust environments in cement plants, limestone quarries, steel mills, and aluminum smelters. Used in asphalt mixing stations, biomass power plants, and chemical processing facilities. Effective for solid-liquid separation in food processing and pharmaceutical industries.

|

Professional filtration factory here now. The best Customized, happy send sample to you confirm quality.

|

||||||

|

1.Polyester filter bag

|

2.Polypropylene filter bag

|

3.Nomex dust filter bag(Aramid)

|

4.PPS dust filter bag

|

|||

|

5.P84 dust filter bag

|

6.Ptfe dust filter bag

|

7.Acrylic dust filter bag

|

8.fiber glass filter bag

|

|||

|

500gsm Polyester filter felt

|

With Polyester yarn and best needle punched line

|

Our quality is top in China

|

|

Dust filter bag for Polyester cement plant widely used in mine,limestone,cement,iron and steel industries,alumina delivery,electrolytic aluminium,non-ferrous metal production,wood processing,food processing and pharmacy industry.

|

||||||

|

Product Specification

|

||

|

Item

|

500gsm polyester filter felt

|

|

|

Construction

|

Needle felt

|

|

|

Fibre Composition

|

Polyester

|

|

|

Scrim Composition

|

Polyester

|

|

|

Felt Area Weight

|

500g/m2(±5%)

|

|

|

Thickness

|

1.8-1.9mm

|

|

|

Mean Air Permeability

|

14-16 m3/m2/min 12.7mmH2O

|

|

|

Breaking Strength-MD(warp)

|

900 N / 5cm

|

|

|

Breaking Strength-CMD(weft)

|

1300 N / 5cm

|

|

|

Breaking Elongation( N/5cm)-MD(warp)

|

20%

|

|

|

Breaking Elongation( N/5cm)-CMD(weft)

|

39%

|

|

|

Dry Shrinkage MD(130℃warp)

|

<1.5%

|

|

|

Dry Shrinkage CMD(130℃weft)

|

<1.5 %

|

|

|

Operating Temperatures

|

<130 deg C

|

|

|

Recommended Maximum Continuous

|

150deg C

|

|

|

Recommended Maximum Surge

|

150deg C

|

|

|

Continuous Temperature

|

150℃

|

|

|

Peak Temperature

|

150℃

|

|

|

Resistance to Hydrolysis

|

Restrict

|

|

|

Resistance to Acids

|

Moderate

|

|

|

Resistance to Alkalis

|

Restrict

|

|

|

Resistance to Oxidation

|

Good

|

|

|

PHValue

|

4-12

|

|

|

Remark

|

Good resistance to oxidation,while limited resistance to acids and alkalis.Service life will be affected by water content under high temperature.

|

|

|

Finish

|

Heat set, singed, calendared

|

|

|

Application

|

|

Application to mine,limestone,cement,iron and steel industries,alumina delivery,electrolytic aluminium,non-ferrous metal production,wood processing,food processing and pharmacy industry.

|

|

Item

|

carbon steel filter cage

|

|

Material

|

Carbon steel galvanized steel stainless steel

|

|

Finish treatment

|

Galvanized organic silicon spray anti-corrosion treatment

|

|

Number of Lingitudinal wire

|

8-24wires(circle type) 10-16 wirtes(Oval type)

|

|

Structure

|

500g/m2(±5%)

|

|

Configuration

|

Single section type bag cage screw joint type doule wire

|

|

ring distrance

|

200mm

|

Why Choose Our Filter Cages?

Our cages reduce system downtime by 50% through precision engineering and corrosion-resistant materials. Engineered in Germany and Italy, they ensure perfect compatibility with all filter bag types.

How Do They Improve Efficiency?

The 200mm ring spacing design lowers pressure drop by 15%, cutting energy costs while maintaining optimal filtration performance.

What Industries Benefit Most?

Cement, steel, mining, and chemical industries see the greatest ROI from reduced maintenance and extended filter bag life.