Description

Delivering ultra-clean air with advanced filtration technology for critical environments.

Cleanroom Operators – Achieve 99.97% Air Purity with HEPA Filter

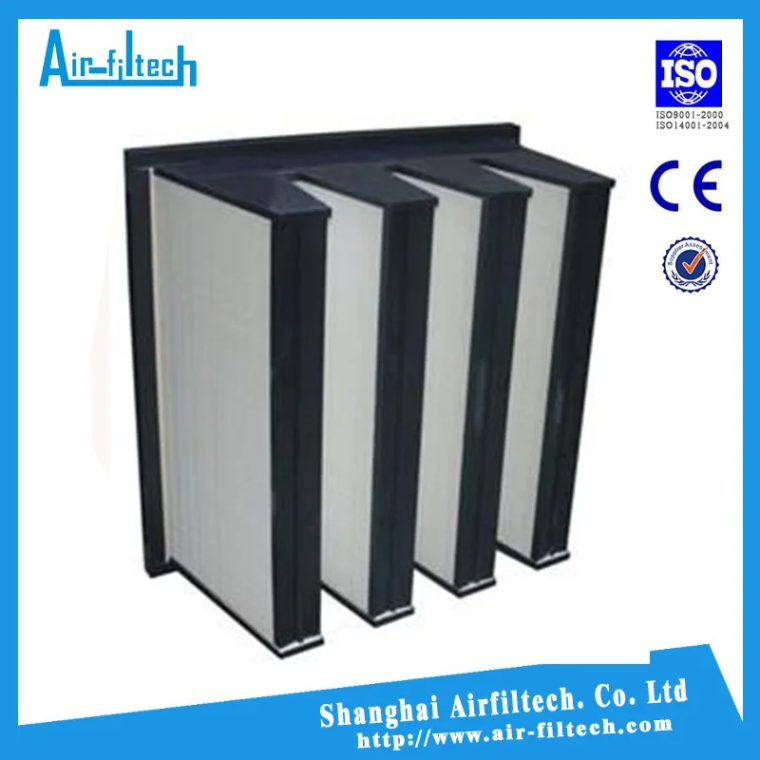

Galvanized/Aluminum/Stainless Steel Frame

Enhances durability and corrosion resistance, extending product lifespan by 40%

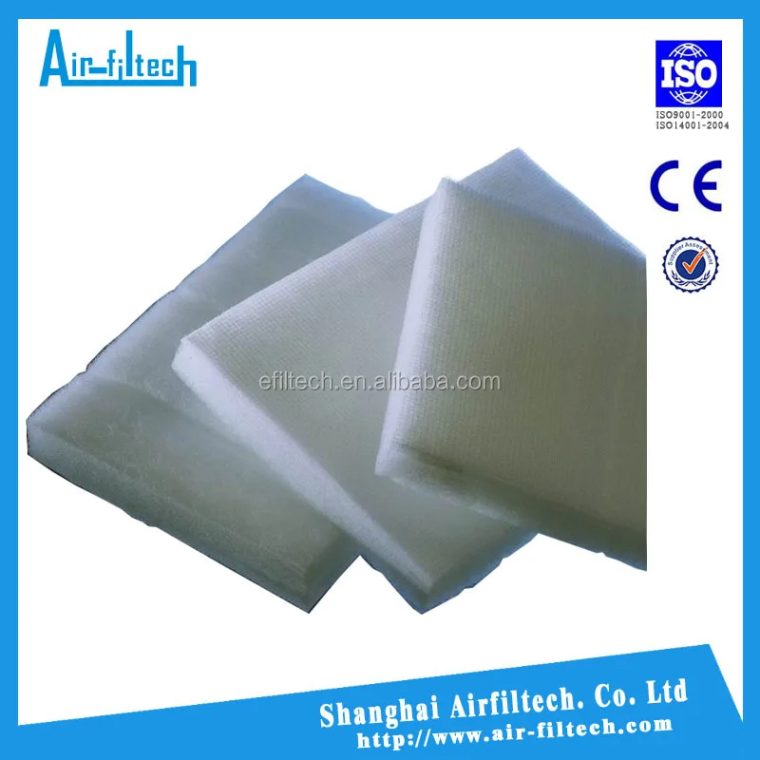

Special Glass Fiber Media

Achieves H13-H14 efficiency (99.97%-99.995% particle capture) for superior air quality

450Pa Recommended Pressure Drop

Optimizes airflow while maintaining filtration effectiveness, reducing energy consumption by 25%

90°C-120°C Temperature Resistance

Enables reliable operation in high-heat industrial environments without performance degradation

DIN53438 F1 Non-Flammability

Meets strict fire safety standards for use in sensitive medical and electronic facilities

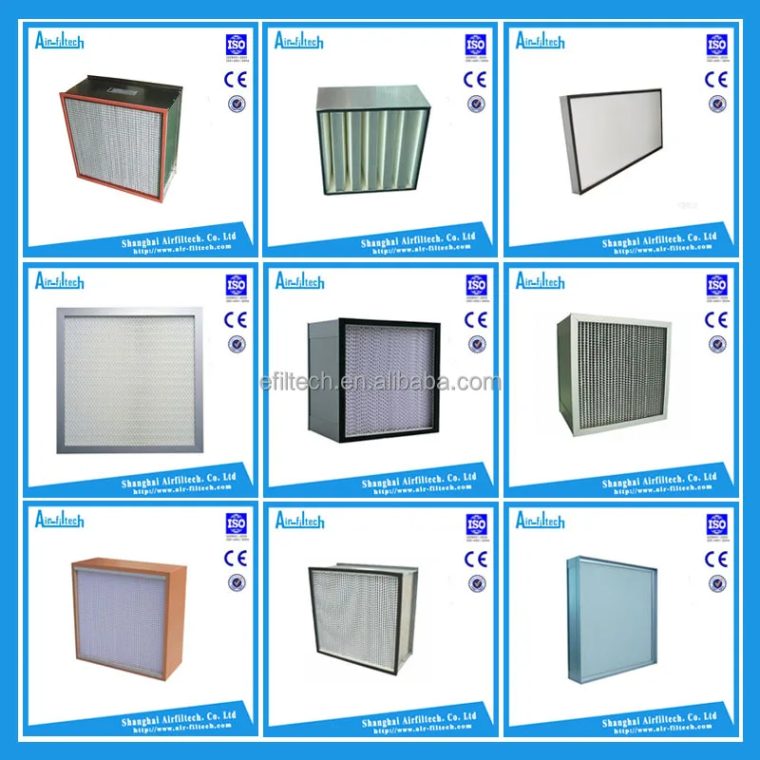

Features

Our HEPA Filter features multiple frame options (galvanized steel, aluminum, stainless steel) with special glass fiber media. The separator uses either special aluminum foil or offset paper. Available in H10-H14 efficiency grades (EN779:2002 standard), each filter undergoes rigorous testing. Dimensions range from compact 305×305×150mm to large 1260×630×220mm models, with media areas from 2.4m² to 50.1m² and airflow capacities up to 4500m³/h.

Benefits

The advanced filtration technology captures 99.97%-99.995% of particles as small as 0.3 microns, ensuring compliance with ISO 14644-1 cleanroom standards. The durable construction withstands harsh environments while maintaining consistent performance. Energy-efficient design reduces operational costs, and the non-flammable certification provides peace of mind in safety-critical applications. Customizable options meet specific industry requirements.

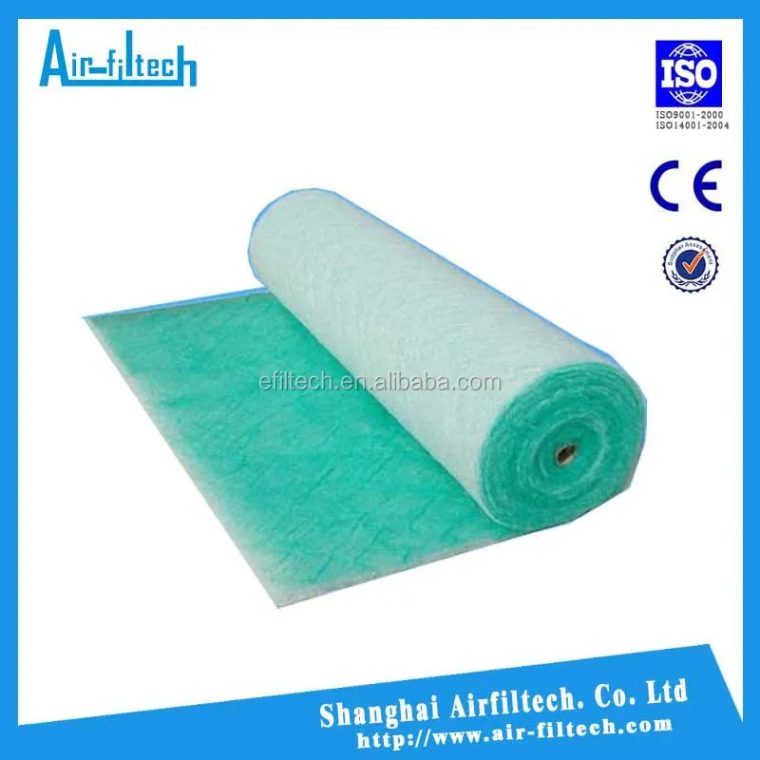

Use Cases

Ideal for electronics manufacturing cleanrooms, hospital operating theaters, pharmaceutical production facilities, and any environment requiring terminal filtration. Specifically designed for vacuum cleaner systems in semiconductor fabrication, biotechnology labs, and precision engineering workshops where air purity directly impacts product quality and yield. The temperature resistance makes it suitable for oven exhaust systems and high-heat industrial processes.

|

Hepa Filter |

Hepa Filter |

Hepa Filter |

Hepa Filter |

Hepa Filter |

||||

|

W*H*D |

W*H*D (mm) |

Standard |

high High air volume |

Standard |

high High air volume |

H10 |

H13 |

H14 |

|

SHH320 |

320*320*220 |

4.1 |

6.1 |

350 |

525 |

90 |

130 |

140 |

|

SHH484/10 |

484*484*220 |

9.6 |

14.4 |

1000 |

1500 |

|||

|

SHH484/15 |

726*484*220 |

14.6 |

21.9 |

1500 |

2250 |

|||

|

SHH484/20 |

968*484*220 |

19.5 |

29.2 |

2000 |

3000 |

|||

|

SHH630/05 |

315*630*220 |

8.1 |

12.1 |

750 |

1200 |

|||

|

SHH630/10 |

630*630*220 |

16.5 |

24.7 |

1500 |

2250 |

|||

|

SHH630/15 |

945*630*220 |

24.9 |

37.3 |

2200 |

3300 |

|||

|

SHH630/20 |

1260*630*220 |

33.4 |

50.1 |

3000 |

4500 |

|||

|

SHH610/03 |

305*305*150 |

2.4 |

3.6 |

250 |

375 |

|||

|

SHH610/05 |

305*610*150 |

5.0 |

7.5 |

500 |

750 |

|||

|

SHH610/10 |

610*310*150 |

10.2 |

15.3 |

1000 |

1500 |

|||

|

SHH610/15 |

915*610*150 |

15.4 |

23.1 |

1500 |

2250 |

|||

|

SHH610/20 |

1220*610*150 |

20.6 |

30.9 |

2000 |

3000 |

|||

|

SHH610/05X |

305*610*292 |

10.1 |

15.1 |

1000 |

1500 |

|||

|

SHH610/10X |

610*610*292 |

20.9 |

31.3 |

2000 |

3000 |

|||

Why Choose Our HEPA Filter?

Our HEPA Filter provides unmatched air purification with 99.97% efficiency, meeting strict cleanroom standards. The durable construction withstands temperatures up to 120°C and features non-flammable certification for safety-critical environments.

How Does It Improve Operations?

By capturing particles as small as 0.3 microns, our filter ensures product quality in electronics manufacturing and reduces contamination risks in medical facilities. The energy-efficient design lowers operational costs while maintaining consistent performance.

What Makes It Differentiated?

Customizable frame materials (galvanized/aluminum/stainless steel) and multiple efficiency grades (H10-H14) allow tailored solutions for specific industry needs. Rigorous testing and ISO 9001 certification guarantee reliability in critical applications.