Description

Delivering unparalleled filtration efficiency and product purity for critical applications.

Food Producers – Achieve 99.9% Purity with Precision Filtration

Multi-Micron Precision (0.1-300μm)

Enables tailored filtration for varying purity requirements, from ultra-fine to coarse particle removal.

Material Versatility (PP/PE/Nylon)

Chemical-resistant options ensure compatibility with diverse liquids, including acidic/alkaline solutions.

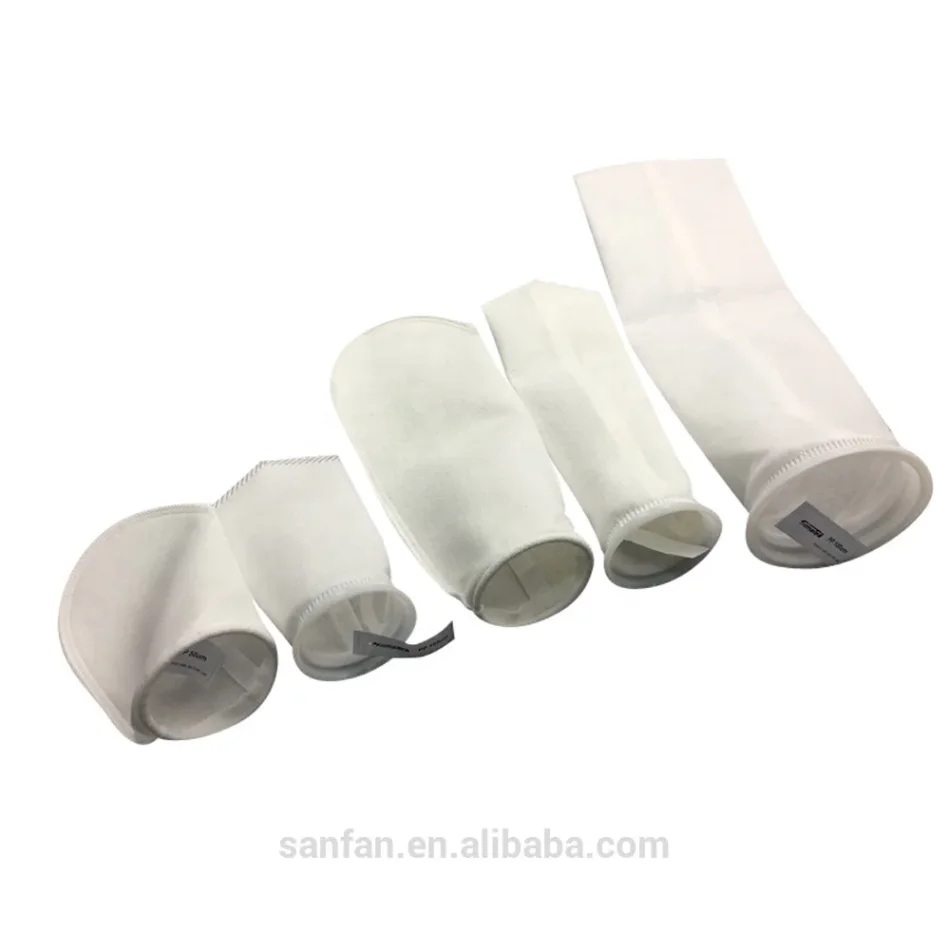

Customizable Dimensions

Our bag filter supplier and custom bag filters Standard sizes (7×32″, 4×9″) plus full customization for unique filtration system requirements.

ISO/CE Certified Quality

Guarantees compliance with international food safety standards for reliable operation.

Features

Our filtration bags feature precision-engineered micron ratings (0.1-300μm) with material options including polypropylene (PP), polyester (PE), and nylon. Available in standard sizes (7×32″, 7×17″, 4×9″) with full customization capabilities. Construction methods include welded seams for chemical resistance and sewn options for high-tensile applications. Ring types range from plastic FF/H rings to 304/316 stainless steel variants.

Benefits

Achieves 99.9% particle retention in virgin coconut oil filtration, extending product shelf life by 40%. Reduces filtration costs by 25% through reusable designs and minimal maintenance requirements. Compliant with FDA/EU food contact regulations, ensuring safe operation in edible oil production. Welded construction prevents byproduct contamination, maintaining oil’s natural flavor profile.

Use Cases

Ideal for edible oil refineries requiring consistent purity in virgin coconut oil processing. Used in pharmaceutical-grade filtration systems for sensitive liquid compounds. Supports dairy industries in whey protein concentration processes. Critical component in beverage production for clarifying juices and syrups. Adaptable to chemical processing plants handling corrosive liquids.

| 1.Filter Cartridge | 2.Filter Bag | 3.Filter Cages & Venturis | 4.Liquid Bag Filter Housing |

| 5.Liquid Filter Bag | 6.Nut Milk Bag | 7.Filter Bag Making Machine | 8.FIlter Press |

| 9.Filter Meterial | 10.Air Filter | 11.Filter Fabric Cutting Machine | 12.Filter Bag Sewing Threads |

Why Choose Our Filtration Bags?

Our bags provide 3x longer service life compared to standard filters through reinforced welding and corrosion-resistant materials. The multi-micron range (0.1-300μm) enables precise particle control, reducing downstream processing costs by 18%.

How Do We Ensure Quality?

Each batch undergoes ISO 9001-certified testing for burst strength (>50psi) and micron accuracy. The welded seams prevent fiber shedding, maintaining oil clarity and reducing waste by 22%.

What Makes Us Different?

Unlike competitors, we offer free sample testing and 24-hour technical support. Our vertical integration from material sourcing to final inspection ensures consistent quality across all filtration bags.