Description

Provides reliable filtration, enhancing operational efficiency and product quality.

Industries – Optimize Filtration with Premium Cloth

Polyester/Polyester Scrim Material

Ensures durability and longevity, reducing replacement costs.

High Air Permeability (12~16 m³/m²/min)

Facilitates efficient air flow, enhancing filtration speed.

Excellent Tensile Strength (>1000N Warp, >1300N Weft)

Withstands high pressure, preventing cloth breakage.

Wide Temperature Range (135°C Dry, 94°C Moist)

Adapts to various operating conditions, ensuring versatility.

Features

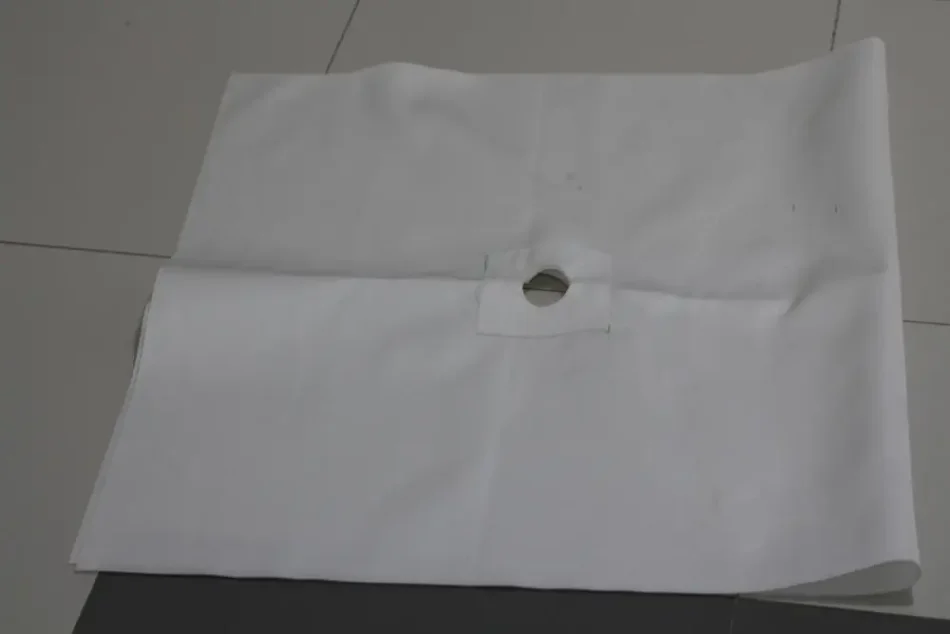

The Filter Press Cloth is crafted from premium polyester or polyester scrim material, ensuring robustness and durability. It features a thickness of 1.9mm and a weight of 500g/sqm, providing a sturdy base for filtration. The cloth’s air permeability ranges from 12 to 16 m³/m²/min, facilitating efficient air flow. With excellent tensile strength (>1000N warp, >1300N weft), it withstands high pressure during filtration. The cloth also exhibits good resistance to alkalis, mineral acids, organic acids, and oxidizing agents, making it suitable for diverse industrial applications.

Benefits

By choosing our Filter Press Cloth, customers can expect enhanced filtration efficiency, leading to improved product quality and reduced downtime. The cloth’s durability and high tensile strength minimize replacement costs, while its wide temperature range ensures adaptability to various operating conditions. Additionally, its resistance to chemicals prolongs its lifespan, providing long-term value for money.

Use Cases

Our Filter Press Cloth is extensively used in the chemical, steel, waste incineration, thermoelectricity, and construction material industries. It serves as an air filter in cement plants, electrical plants, asphalt plants, and wastewater treatment workshops. The cloth’s versatility and durability make it an ideal choice for industries requiring reliable and efficient filtration solutions.

|

Specs forpolyester needle felt

|

||||||||||

|

Material

|

Polyester/Polyester Scrim

|

Thickness

|

1.9

|

|||||||

|

Weight(g/sqm)

|

500

|

Density(g/cm³)

|

1.38

|

Air Permeability (m³/m²/min)

|

12~16

|

|||||

|

Warp Tensile Strength(N/5x20cm)

|

>1000

|

Weft Tensile Strenght(N/5x20cm)

|

>1300

|

Moisture Regain(20°C And 65% r. humidity)

|

0.10%

|

|||||

|

Warp Elongation(%)

|

<30

|

Weft Elongation(%)

|

<50

|

Support Combustion

|

Yes

|

|||||

|

Continuous Dry Heat Operation(°C)

|

135

|

Continuous Moist Heat Operation(°C)

|

94

|

Max Short Dry Heat Surge(Short Term)(°C)

|

150

|

|||||

|

Biological(Mildew, Bacteria)

|

fair

|

Alkalis

|

fair

|

Mineral Acids

|

fair

|

|||||

|

Organic Acids

|

fair

|

Oxidising Agents

|

good

|

Organic Solvents

|

good

|

|||||

|

Finishing

|

Singeing-calendering-heat setting

|

|||||||||

|

Product Applications

|

Chemical/ Steel/Waste Incineration/Thermoelectricity/Construction Material

|

|||||||||

|

Usage

|

Air Filter

|

|||||||||

|

Type

|

Filter Felt

|

|||||||||

|

Specialized in supplying

|

||||||||||

|

1. Needle puched felt 2. Woven filtration fabric 3. Filter bags 4. Filter cages 5. Filter tubing automatic production line

|

||||||||||

|

Item

|

Polyproplene filter felt

|

|

Construction

|

Needle felt

|

|

Fibre Composition

|

Polyproplene or nylon

|

|

Micro rating

|

1um 5um 10um 25um 50um 75um 100um 125um 150um 200um 250um 300um

|

|

Continuous Temperature

|

90℃

|

|

Peak Temperature

|

95℃

|

|

Resistance Hydrolysis

|

Excellent

|

|

Resistance to Acids

|

Excellent

|

|

Resistance to Alkalis

|

Excellent

|

|

Resistance to Oxidation

|

Restrict

|

|

PHvalue

|

1-14

|

|

Application

|

Application to food ,flour.sugar,fertilizer,electropating and pesticide industries

|

|

Remark

|

Restrict resistance to oxidation,but excellent resistance to hydrolysis

|

|

Item

|

Dia(inch)

|

length

|

mm

|

|

1#

|

7″

|

17″

|

180X420

|

|

2#

|

7″

|

32″

|

180X810

|

|

3#

|

4″

|

9″

|

102X230

|

|

4#

|

4″

|

15″

|

102X410

|

|

5#

|

6″

|

22″

|

152×559

|

|

Material

|

PE,PP,NMO

|

|

Bag top ring

|

Plastic ring, Stainless steel ring

|

|

Relative filtration pore size

|

0.5, 1,5, 10, 25, 50, 100, 200 ,300µm

|

|

Type

|

various specifications

|

|

Airtight method:

|

Hot Melt, reverse sewing

|

|

Effective filtration area

|

various specifications

|

|

Others

|

special requirement of diameter and collar extension can be customized

|

Why Choose Our Filter Press Cloth?

Our Filter Press Cloth is designed for high-performance filtration, ensuring reliable and efficient operation in various industries. Its durability, high tensile strength, and chemical resistance make it a cost-effective solution for long-term use.

How Does It Benefit Your Operations?

By using our Filter Press Cloth, you can expect improved product quality, reduced downtime, and minimized replacement costs. Its wide temperature range and adaptability to different operating conditions ensure versatility and reliability.

Where Can It Be Applied?

Our Filter Press Cloth is suitable for a wide range of industries, including chemical, steel, waste incineration, thermoelectricity, and construction material. It serves as an air filter in various plants and workshops, providing efficient and reliable filtration.