Description

Our filter bags are designed to optimize system performance, reduce emissions, and lower maintenance costs across various industrial sectors.

Industries – Minimize Downtime with Premium Filter Bags

Aramid/Nomex Material

High-temperature resistance up to 200°C, ideal for cement and power station applications.

PTFE Membrane Option

Achieves near-zero emissions for waste processing and power station boilers.

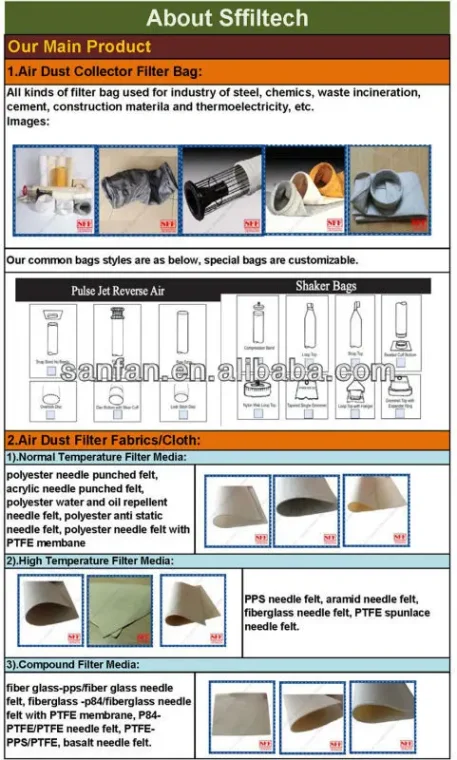

Customizable Designs

Oval, flat, envelope, and support ring types tailored to specific industry needs.

Process-Specific Engineering

Optimizes flow parameters for maximum productivity in chemical and cement industries.

Features

Our filter bags are crafted from high-quality materials including aramid (Nomex), polyester, polypropylene, and glass fiber. Available in needle felt and woven variants, they come with optional treatments like PTFE membrane, anti-static, water and oil repellent coatings. Customizable dimensions range from 115-200mm diameter and 2000-9000mm length.

Benefits

Clients benefit from reduced emissions, increased production efficiency, and lower maintenance costs. The PTFE membrane option ensures near-zero emissions, while the aramid material withstands high temperatures, extending the filter bag’s lifespan. Custom designs cater to specific industry requirements, enhancing overall system performance.

Use Cases

Our filter bags are widely used in the chemical industry for comprehensive solutions, including expert support in filter bag design and system flow parameter optimization. In the cement industry, they provide high-performance filtration for kiln/mill, alkali, and pulse jet applications. For power stations and incineration facilities, they offer near-zero emissions solutions, compatible with various fuel types and waste processing methods.

Why Choose Our Filter Bags?

Our filter bags are engineered for high-performance in industrial settings, offering customizable designs, superior materials, and process-specific engineering. They reduce emissions, increase productivity, and lower maintenance costs.

Key Features

High-temperature resistance, PTFE membrane option, customizable dimensions, and expert support in design and system optimization.

Industry Applications

Suitable for chemical, cement, power station, and incineration industries. Provides near-zero emissions solutions and enhances system performance.