Description

Enhance industrial filtration efficiency and ensure superior separation.

Industries – Achieve Efficient Separation with Felt Filter

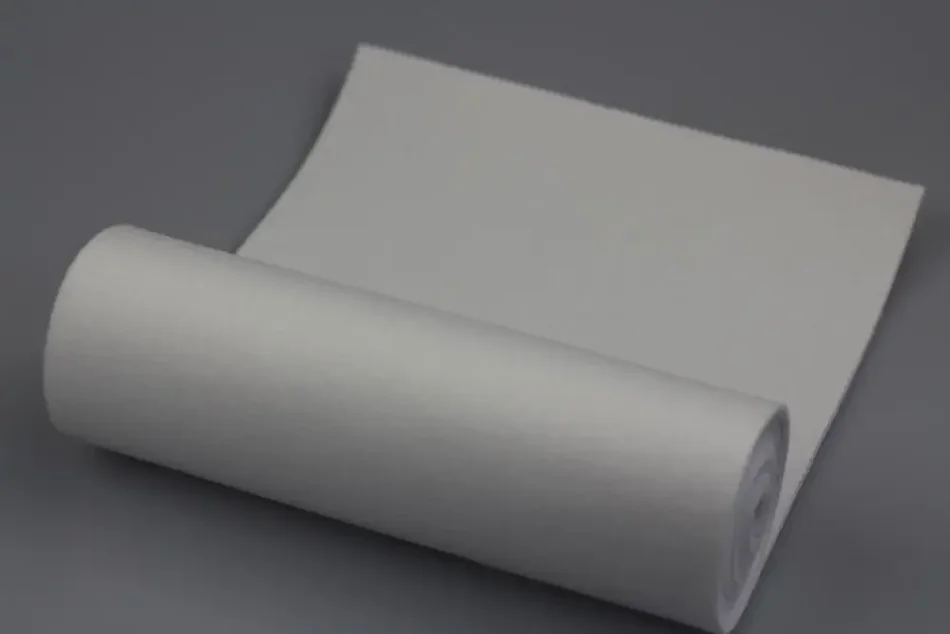

High-Quality Material

Durable and long-lasting, ensuring consistent performance over time.

Wide Range of Micro Ratings

Offers versatility in filtration needs, from 1um to 300um.

Excellent Resistance Properties

Resistant to hydrolysis, acids, alkalis, and oxidation, ensuring reliability in harsh conditions.

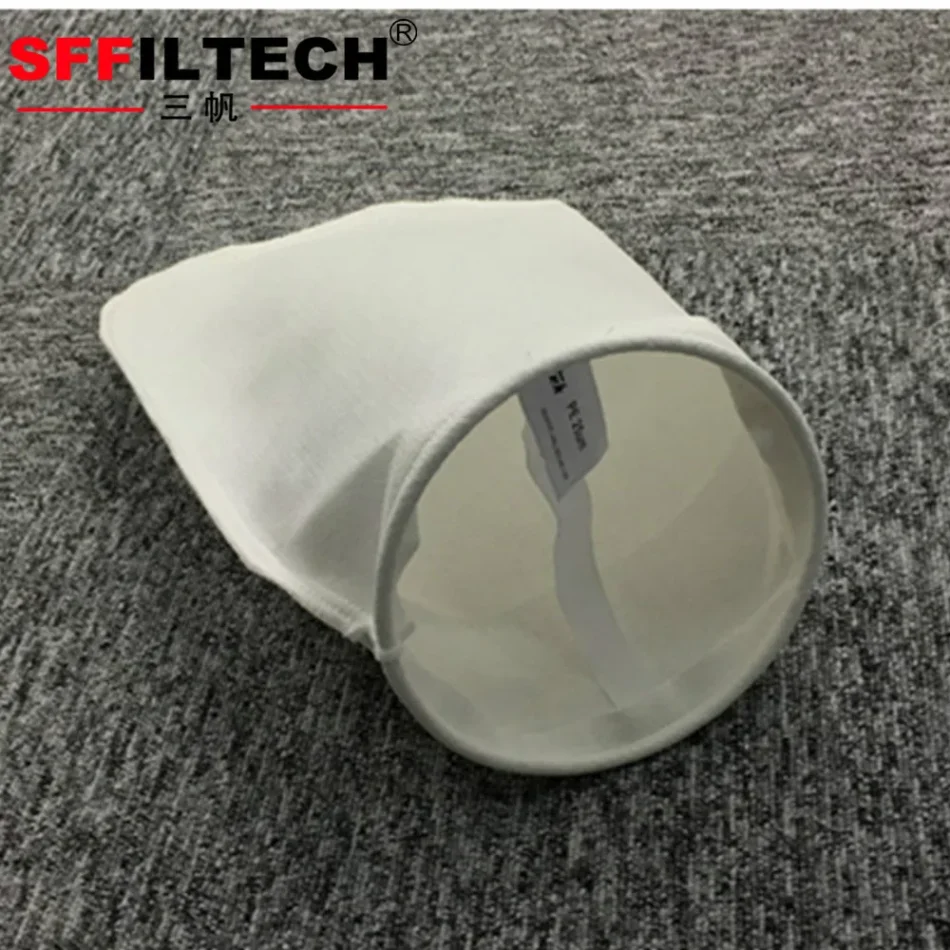

High Temperature Tolerance

Withstands continuous temperatures up to 90°C and peak temperatures up to 95°C.

Features

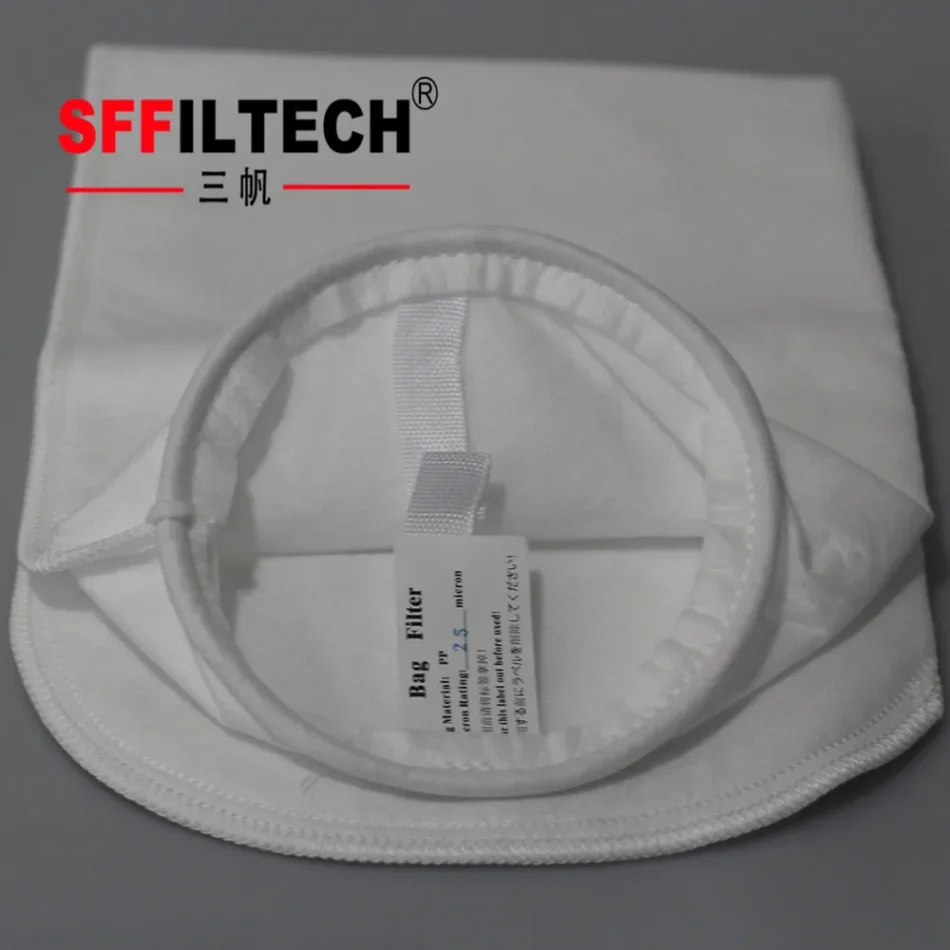

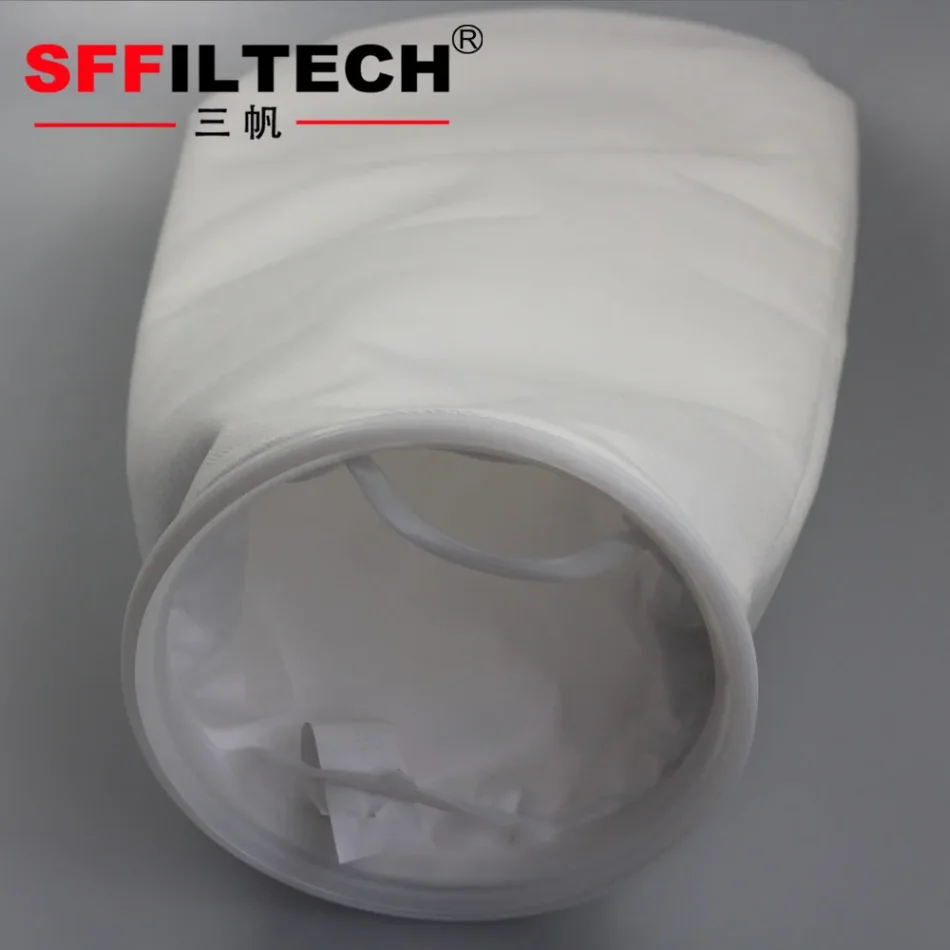

The felt filter cloth for industrial filtration is crafted from premium polypropylene or nylon materials, ensuring durability and longevity. It comes in a wide range of micro ratings (1um to 300um), catering to various filtration needs. The filter sock for industrial processes is designed with excellent resistance properties, including hydrolysis, acids, alkalis, and oxidation, making it suitable for harsh industrial environments. Additionally, it can withstand high temperatures, with continuous operation up to 90°C and peak temperatures up to 95°C.

Benefits

The felt filter bag for industrial use provides superior filtration efficiency, ensuring clean and pure output. Its wide range of micro ratings allows for flexibility in applications, from fine dust filtration to coarse particle separation. The excellent resistance properties extend the filter’s lifespan, reducing the need for frequent replacements and saving costs. High temperature tolerance ensures reliable performance even in extreme conditions, minimizing downtime and maximizing productivity.

Use Cases

The industrial felt filter for efficient separation is ideal for a variety of industries, including cement, limestone, iron and steel, alumina delivery, electrolytic aluminum, non-ferrous metal production, wood processing, food processing, and pharmacy. It is specifically designed for industrial processes that require high-efficiency filtration, such as asphalt mixing plants, biomass power stations, chemical and pharmaceutical industries, high-temperature dedusting, coal-fired power stations, and thermal waste treatment. Its versatility and superior performance make it a preferred choice for industries seeking reliable and efficient filtration solutions.

|

Item

|

Polyproplene filter felt

|

|

Construction

|

Needle felt

|

|

Fibre Composition

|

Polyproplene or nylon

|

|

Micro rating

|

1um 5um 10um 25um 50um 75um 100um 125um 150um 200um 250um 300um

|

|

Continuous Temperature

|

90℃

|

|

Peak Temperature

|

95℃

|

|

Resistance Hydrolysis

|

Excellent

|

|

Resistance to Acids

|

Excellent

|

|

Resistance to Alkalis

|

Excellent

|

|

Resistance to Oxidation

|

Restrict

|

|

PHvalue

|

1-14

|

|

Application

|

Application to food ,flour.sugar,fertilizer,electropating and pesticide industries

|

|

Remark

|

Restrict resistance to oxidation,but excellent resistance to hydrolysis

|

Why Choose Felt Filter for Industrial Use?

The felt filter is specifically designed for industrial processes, offering superior filtration efficiency and durability. Its wide range of micro ratings and excellent resistance properties make it suitable for various industries, ensuring clean and pure output while reducing costs.

How Does Felt Filter Enhance Filtration Efficiency?

The felt filter's high-quality material and wide range of micro ratings allow for precise filtration, capturing even the finest particles. Its excellent resistance properties ensure consistent performance over time, minimizing downtime and maximizing productivity.

What Industries Benefit from Felt Filter?

Industries such as cement, limestone, iron and steel, alumina delivery, electrolytic aluminum, non-ferrous metal production, wood processing, food processing, and pharmacy benefit from the felt filter's superior filtration efficiency and durability. It is ideal for industrial processes that require high-efficiency filtration, ensuring clean and pure output.