Description

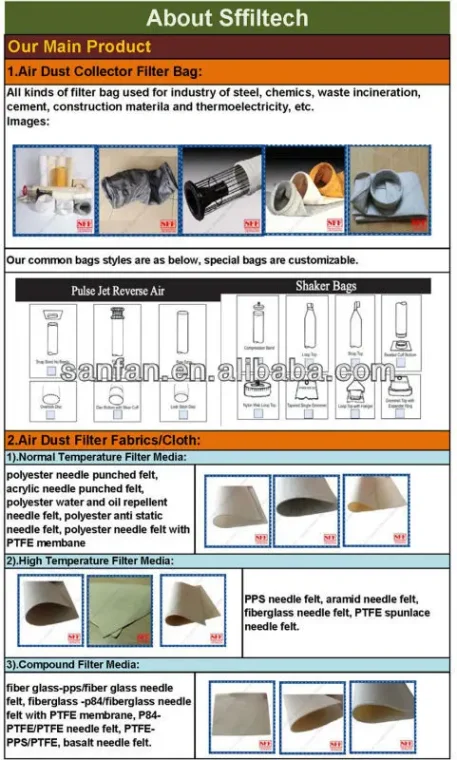

Providing high-quality felt filter solutions for efficient industrial separation and filtration.

Industries – Efficient Separation with Felt Filter

Polyester Needle Felt Construction

Enhances durability and filtration efficiency, ideal for harsh industrial environments.

High Area Weight (550g/m2)

Ensures robust filtration performance, capturing fine particles effectively.

Excellent Air Permeability (10-15m3/m2/min@127Pa)

Facilitates smooth airflow, reducing pressure drop and energy consumption.

High Breaking Strength (>900N/5*20cm MD, >1300N/5*20cm CMD)

Provides exceptional tear resistance, extending filter lifespan.

Heat Set, Singed, Calendered Finish

Improves surface smoothness and filtration accuracy, enhancing overall performance.

Features

The felt filter material is constructed from polyester needle felt, featuring a high area weight of 550g/m2 and a thickness ranging from 2.1-2.3MM. It exhibits excellent air permeability of 10-15m3/m2/min at 127Pa, ensuring efficient airflow. The breaking strength exceeds 900N/5*20cm in the machine direction (MD) and 1300N/5*20cm in the cross-machine direction (CMD), providing robust durability. The felt filter also boasts low breaking elongation (<20% MD, <40% CMD) and minimal dry shrinkage (<1.5% at 130°C), ensuring dimensional stability.

Benefits

Our felt filter material offers numerous benefits for industrial applications. Its high area weight and excellent air permeability make it ideal for efficient separation and filtration processes. The robust breaking strength ensures long-lasting performance, reducing the need for frequent replacements. Additionally, the low breaking elongation and dry shrinkage maintain filter integrity, even under harsh operating conditions. This translates to cost savings, improved productivity, and enhanced environmental protection.

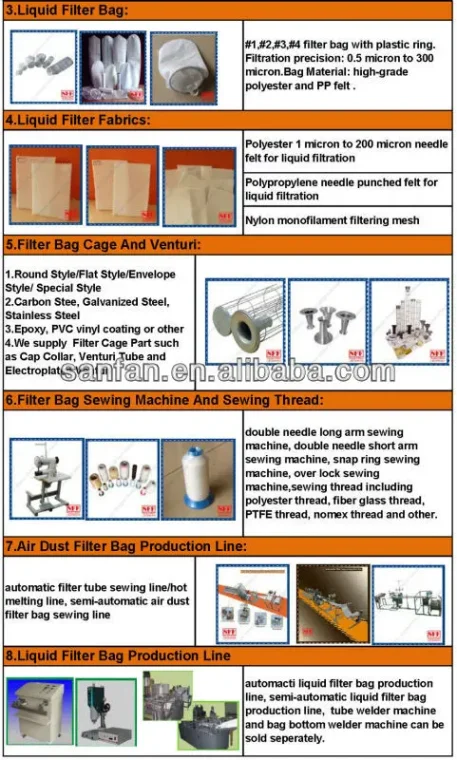

Use Cases

The felt filter material is widely used in industrial separation and filtration applications. It is particularly suitable for scenarios requiring efficient particle capture, such as in chemical processing, metalworking, and power generation. The material’s durability and high filtration efficiency make it an excellent choice for industries seeking to improve air quality, reduce emissions, and comply with environmental regulations. Whether used in bag filters, cartridge filters, or other filtration systems, our felt filter material delivers reliable performance.

| Construction | Needle felt |

| Fibre Composition | Polyester |

| Scrim Composition | Polyester |

| Felt Area Weight | 550g/m2 |

| Thickness | 2.1-2.3MM |

| Mean Air Permeability | 10-15m3/m2/min@127Pa |

| Breaking Strength-MD(warp) | >900N/5*20cm |

| Breaking Srength-CMD(weft) | >1300N/5*20cm |

| Breaking Elongation(N/5cm)-MD(warp) | <20% |

| Breaking Elongation(N/5cm)-CMD(weft) | <40% |

| Dry Shrinkge-MD(130 degree celsius warp | <1.5% |

| Dry Shrinkage-CMD(130 degree celsius weft | <1.5% |

| Operating Temperatures | |

| Recommended Maximum Continuous | 130 degree celsius |

| Recommended Maximum Surge | 150 degree celsius |

| Finish | heat set, singed, calendered,W/O repellent |

| payment terms | L/C, T/T, Western union, Money gram,Paypal |

| MOQ | 1 square meter |

| OEM | available |

| Certificate | ISO. Reach standard |

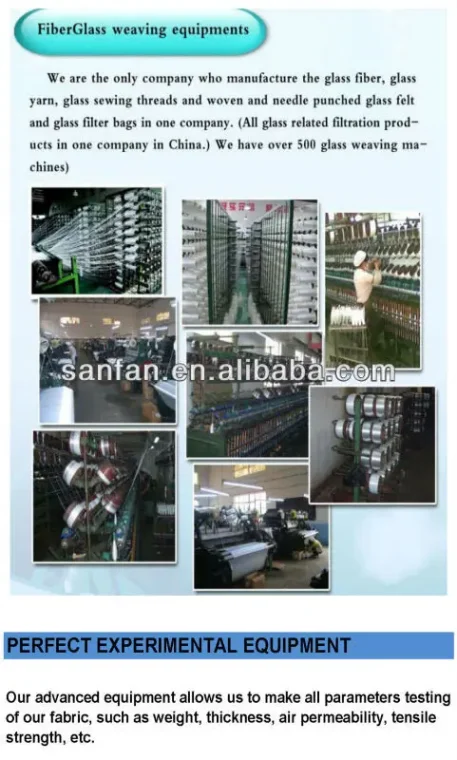

Why Choose Our Felt Filter?

Our felt filter material stands out for its exceptional durability, high filtration efficiency, and cost-effectiveness. It is specifically designed for industrial applications, ensuring reliable performance in harsh environments.

How Does It Benefit Industries?

Industries benefit from our felt filter by achieving efficient separation and filtration, reducing energy consumption, and complying with environmental regulations. Its robust construction and excellent air permeability make it an ideal choice for various industrial scenarios.

What Makes It Different?

Unlike traditional filter materials, our felt filter offers a higher area weight, superior breaking strength, and minimal dry shrinkage. These features ensure long-lasting performance and reduced maintenance costs, setting it apart from competitors.