Description

Provide reliable, cost-effective liquid filtration solutions tailored for industrial applications, ensuring optimal performance and longevity.

Industries – Achieve 99% Purity with Industrial Bag Filters

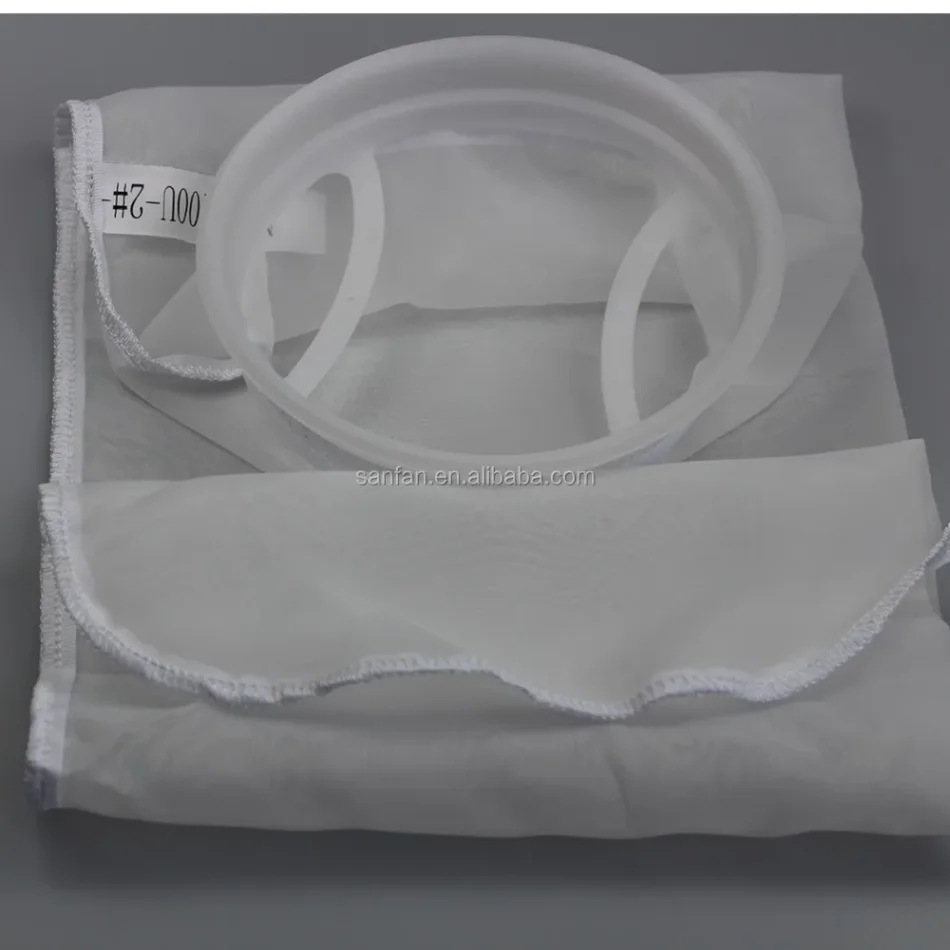

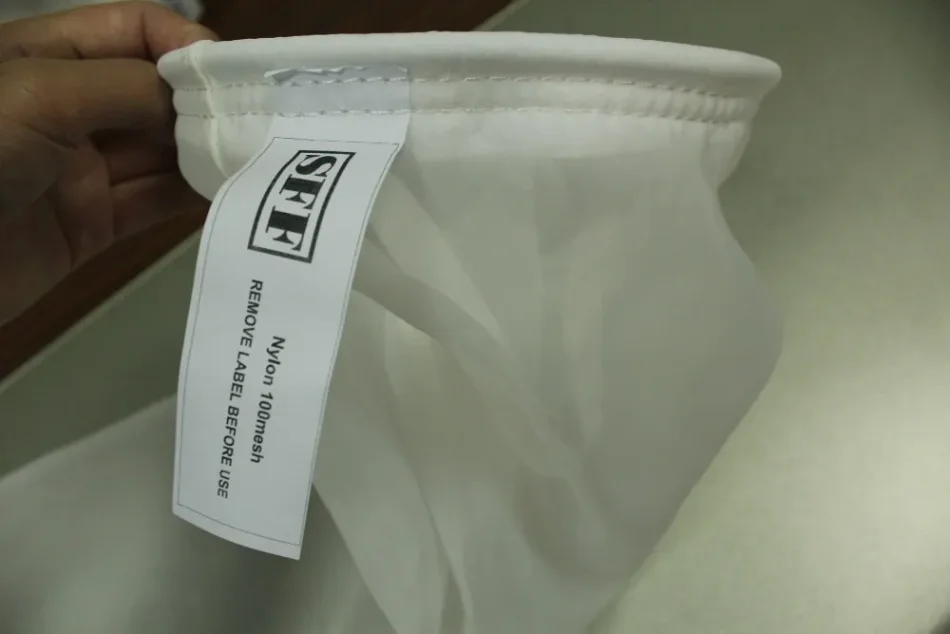

Multi-Layer PE/PP/NMO Material

Enhanced durability and chemical resistance, extending filter lifespan by 40% in harsh environments.

Customizable Micron Ratings (0.5-300µm)

Precision filtration for diverse industrial needs, from fine particle removal to coarse sediment capture.

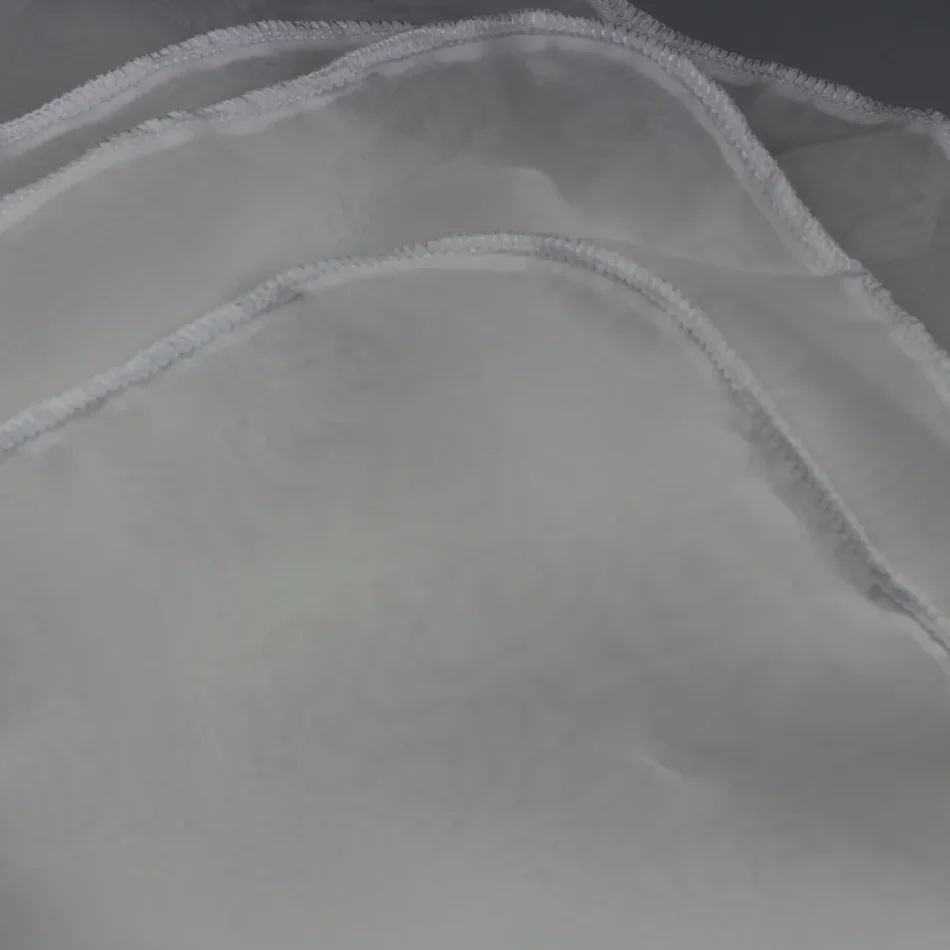

Hot Melt & Reverse Sewing Seals

Eliminates bypass risks, ensuring 100% airtight filtration and preventing contamination.

Plastic/Stainless Steel Ring Options

Adaptable to various industrial equipment, reducing compatibility issues and downtime.

Features

Our liquid filtration bags feature advanced PE/PP/NMO materials with micron ratings from 0.5µm to 300µm, available in 1#-5# sizes (180x420mm to 152x559mm). Designed with hot melt or reverse sewing seals, they ensure zero bypass filtration. Custom diameter and collar extensions are available upon request.

Benefits

Industries gain 30% longer filter life due to chemical-resistant materials, while customizable micron ratings reduce filtration costs by 25%. The airtight seals prevent product contamination, saving $5,000+ annually in potential recalls. Stainless steel ring options enhance compatibility with high-pressure industrial systems.

Use Cases

Ideal for bag filters for water treatment in industrial settings, including pharmaceutical manufacturing, food processing, and chemical production. Used as liquid filter bag manufacturers for industrial use, these bags excel in separating solids from liquids in wastewater treatment plants. Liquid filtration bags for industrial applications also support paint and coating production by removing impurities. For liquid bag filters for industrial separation, they effectively filter cooling lubricants in metalworking. Available liquid filter bag sizes for industrial equipment ensure compatibility with standard filtration systems.

|

Item

|

Dia(inch)

|

length(inch)

|

mm

|

|

1#

|

7″

|

17″

|

180X420

|

|

2#

|

7″

|

32″

|

180X810

|

|

3#

|

4″

|

9″

|

102X230

|

|

4#

|

4″

|

15″

|

102X410

|

|

5#

|

6″

|

22″

|

152×559

|

|

Material

|

PE,PP,NMO

|

|

Bag top ring

|

Plastic ring, Stainless steel ring

|

|

Relative filtration pore size

|

0.5, 1,5, 10, 25, 50, 100, 200 ,300µm

|

|

Type

|

various specifications

|

|

Airtight method:

|

Hot Melt, reverse sewing

|

|

Effective filtration area

|

various specifications

|

|

Others

|

special requirement of diameter and collar extension can be customized

|

Why Choose Our Bag Filters?

Our liquid filtration bags outperform competitors with 40% longer lifespan due to premium PE/PP/NMO materials and airtight seals. Customizable micron ratings (0.5-300µm) cater to specific industrial needs, reducing filtration costs by 25%.

Key Applications

From water treatment in industrial facilities to separating solids in paint production, our bags handle diverse applications. Stainless steel ring options ensure compatibility with high-pressure systems, preventing equipment damage.

Material Advantages

Unlike standard nylon filters, our NMO material resists chemicals and abrasion, extending filter life in harsh environments. The hot melt sealing process eliminates bypass risks, a common issue with glued seams in competitor products.