Description

Provides reliable and efficient filtration in high-temperature environments, ensuring cleaner air and prolonged equipment life.

Industries – High-Temperature Filtration – Aramid Excellence

High-Temperature Resistance

Withstands temperatures up to 240°C, ensuring consistent performance in extreme conditions.

Superior Breaking Strength

>800 N warp and >1200 N weft breaking strength, providing durability and longevity.

Low Dry Shrinkage

<1% dry shrinkage at 130°C, maintaining dimensional stability and filtration efficiency.

Excellent Air Permeability

12-15 m³/m²/min air permeability, ensuring efficient filtration and airflow.

Features

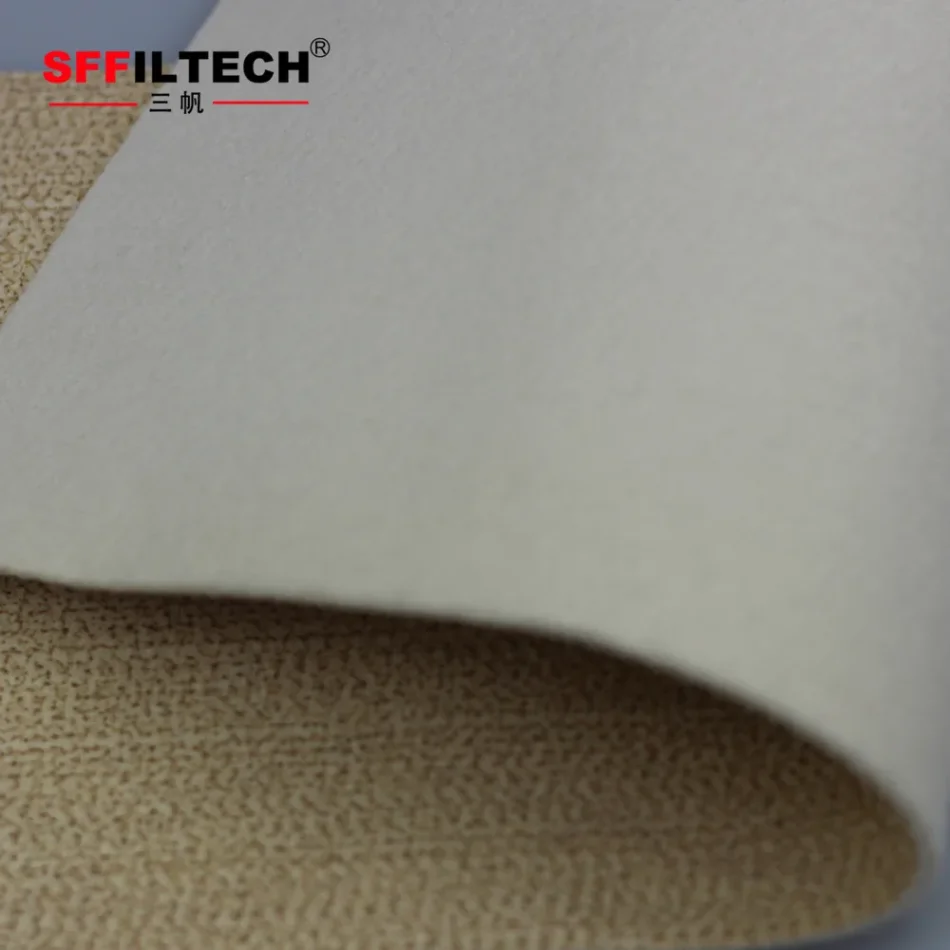

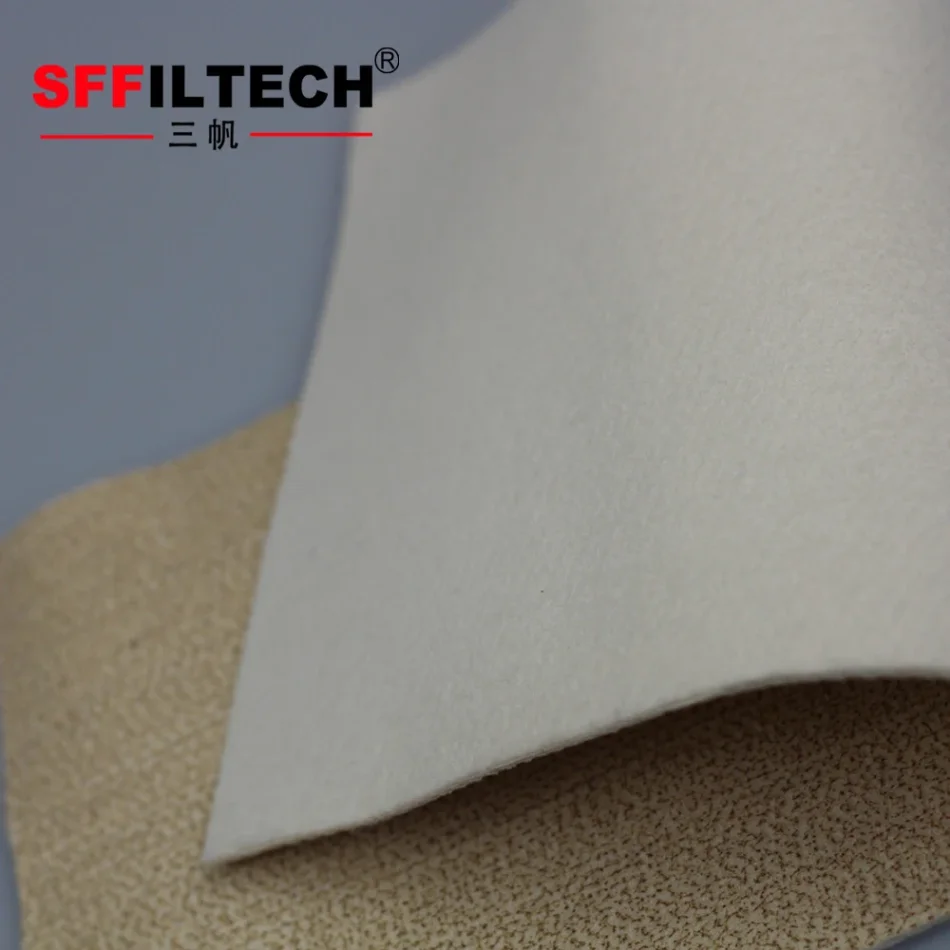

The Aramid Fiber Felt is crafted from high-quality aramid fibers, featuring a needle-felt construction. It has a felt area weight of 500g/m² (±5%) and a thickness of 2.1-2.3mm. The mean air permeability is 12-15 m³/m²/min at 12.7mmH2O, ensuring efficient airflow and filtration. The breaking strength exceeds 800 N in the warp direction and 1200 N in the weft direction, providing exceptional durability. Additionally, it exhibits low dry shrinkage (<1%) at 130°C, maintaining its shape and performance even under high-temperature conditions.

Benefits

The Aramid Fiber Felt offers numerous benefits to industries requiring high-temperature filtration. Its superior breaking strength ensures long-lasting performance, reducing the need for frequent replacements. The low dry shrinkage maintains consistent filtration efficiency, preventing clogging and pressure drops. The excellent air permeability allows for efficient airflow, enhancing overall system performance. By choosing this aramid fiber felt, industries can achieve cleaner air, protect equipment from dust damage, and reduce maintenance costs.

Use Cases

The Aramid Fiber Felt is widely used in various industrial applications requiring high-temperature filtration. It is ideal for asphalt mixing plants, biomass power stations, chemical industries, coal-fired power stations, food industries, non-ferrous metal and steel production, cement, gypsum, and lime industries, as well as thermal waste treatment facilities. Its ability to withstand extreme temperatures and maintain filtration efficiency makes it a preferred choice for these demanding environments.

| 1.Filter Cartridge | 2.Filter Bag | 3.Filter Cages & Venturis | 4.Liquid Bag Filter Housing |

| 5.Liquid Filter Bag | 6.Nut Milk Bag | 7.Filter Bag Making Machine | 8.FIlter Press |

| 9.Filter Meterial | 10.Air Filter | 11.Filter Fabric Cutting Machine | 12.Filter Bag Sewing Threads |

| Construction | Needle felt |

| Fibre Composition | Aramid |

| Scrim Composition | Aramid |

| Felt Area Weight | 500g/m2(±5%) |

| Thickness | 2.1-2.3mm |

| Mean Air Permeability | 12-15 m3/m2/min at 12.7mmH2O |

| Breaking Strength-MD(warp) | >800 N / 5*20cm |

| Breaking Strength-CMD(weft) | >1200 N / 5*20cm |

| Breaking Elongation( N/5cm)-MD(warp) | <35% |

| Breaking Elongation( N/5cm)-CMD(weft) | <50% |

| Dry Shrinkage MD(130℃warp) | <1% |

| Dry Shrinkage CMD(130℃weft) | <1% |

| Operating Temperatures | 204 deg C |

| Recommended Maximum Continuous | 204 deg C |

| Recommended Maximum Surge | 240 deg C |

| Finish | singed /calendared/ heat set |

| Dust filtration |

Filter Felt:polyester non woven fabric, polypropylene non woven fabric, PPS non woven fabric, PTFE non woven fabric, FMS non woven fabric, Fiberglass non woven fabirc, nomex aramid fabric: 300gsm nomex aramid fabric, 350gsm nomex aramid fabric, 400gsm nomex aramid fabric, 450gsm nomex aramid fabric, 500gsm nomex aramid fabric, 550gsm nomex aramid fabric, 600gsm nomexaramid fabric, water and oil repellent nomex aramid fabric, PTFE coated nomex aramid fabric, PTFE dipping nomex aramid fabric, PTFE membrane nomex aramid fabric, Antistatic nomex aramid fabric,fiberglass scrim nomex aramid fabirc |

| Liquid filtration | Liquid filtration Polyester pleated bag filter, PE pleated bag filter, Micro pleated bag filter,5 micro pleated bag filter,10 micro pleated bag filters,PP pleated bag filter,nylon pleated bag filter,ptfe pleated bag filter,stainsteel pleated bag filter and so on. |

| Machines | Machines for dust filtration Automatic pleated bag filter tube line,Semi-Automatic pleated bag filter tube line,Tripe-needle pleated bag filter sewing machine,double need sewing machine, long arm sewing machine,overlock sewing machine,slitting machine,pleated bag filter bottom punching machin package machines needle punch line and |

| Usagae/Occasion | pleated bag filter can be used for industrial filtration,product filtration solid/liquid separation, like: – Asphalt mixing plants – Biomass power stations – Chemical l industry – High temperature dedusting – Coal-fired power stations – Food industry – Non-ferrous metal and steel production – Cement, gypsum and lime industry – Thermal waste treatment |

| About us | 1.Trade Assrurance, with trade assurance,you’ll enjoy: 100% product quality protection 100% on-time shipmeng protection 100% payment protection for your covered amount 2.Gold supplier 3.We accept transactions via alibaba.com 4.Payment protection 5.on-time shipment 6.wholesal low MOQS 7.Popular Buying requests for”pleated bag filter”and “Nut milk bag” |

| Size and Design Any size is avaiable, we will follow you size and design | |

| MOQ(small order accept) | 50pcs is also accept |

| Price | We are factory(Our factory add for you check at any time) |

| delivery time | Samples: usually shiped one day, orders, 2000pcs pleated bag filters mass 7-15days.biggest order depengds on your quantity. |

| Package Detail | We have general packing,paper carton with plastic bag inside, some time with pallets. |

| Warm Tips | More products details,our advantage,package detail,delivery time, samples and so on |

Why Choose Aramid Fiber Felt?

Aramid Fiber Felt is specifically designed for high-temperature filtration applications. Its unique properties, such as high-temperature resistance, superior breaking strength, and low dry shrinkage, make it an ideal choice for industries requiring reliable and efficient filtration.

How Does It Benefit Industries?

By using Aramid Fiber Felt, industries can achieve cleaner air, protect equipment from dust damage, and reduce maintenance costs. Its durability and efficiency ensure consistent performance, even in extreme conditions.

What Makes It Stand Out?

Compared to other filtration media, Aramid Fiber Felt offers exceptional high-temperature resistance and breaking strength. Its low dry shrinkage maintains filtration efficiency, preventing clogging and pressure drops. These features make it a superior choice for demanding industrial applications.