Polyester Needle vs Felt: Filter Bag Showdown

In the world of industrial filtration, choosing the right filter bag can make or break your system’s efficiency. Today, we’re diving deep into the comparison of two popular options: polyester needle felt filter bags vs polyester felt filter bags. Ever wondered which one suits your specific industrial needs better? Let’s unravel the mysteries behind their material, structure, and performance to help you make an informed decision.

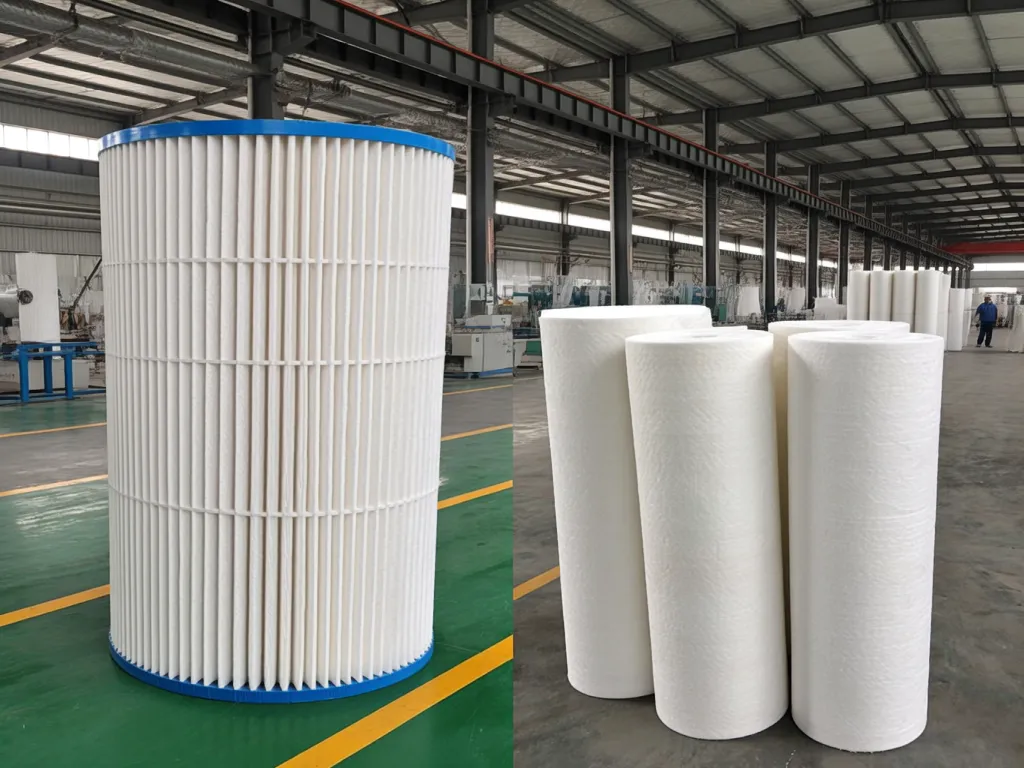

Material and Structural Differences: Analyzing How Needle-Punching Enhances Polyester Needle Felt Filter Bags vs. Simple Structures of Polyester Felt Filter Bags

When it comes to industrial filtration, the choice between polyester needle felt filter bags and polyester felt filter bags can significantly impact both performance and cost. So, what sets these two types of filter bags apart? Let’s dive into the material and structural differences that make each unique and how these factors influence their filtering capabilities and longevity. First, let’s talk about the polyester needle felt filter bag. This type of filter bag is crafted using a specialized needle-punching process. During manufacturing, fine polyester fibers are mechanically intertwined using thousands of barbed needles. This process creates a dense, three-dimensional fabric structure with numerous tiny interstices. These tiny openings are crucial because they allow for efficient particle capture while maintaining good airflow. The needle-punching technique enhances the fabric’s surface area, which translates to improved filtration efficiency. The three-dimensional structure of polyester needle felt filter bags means they can trap finer particles compared to their simpler counterparts. Moreover, this intricate weave provides excellent mechanical stability. The interlocked fibers resist abrasion and wear, making the filter bag more durable and less prone to tearing or fraying. This durability is especially beneficial in harsh industrial environments where the filter bags are subjected to constant pressure and abrasive particles. For high-performance filtration solutions, explore our range of high-efficiency felt filters. In contrast, polyester felt filter bags have a simpler structure. They are made by layering and bonding polyester fibers without the intensive needle-punching process. While this results in a less complex fabric, it also means fewer interstices and a lower surface area for particle capture. As a result, polyester felt filter bags generally have coarser filtration capabilities. They are better suited for applications where large particles need to be filtered out, and fine particle retention is not critical. The simplicity of polyester felt filter bags does have its advantages. They are typically less expensive to produce and purchase, making them a cost-effective option for certain industrial settings. Additionally, their straightforward construction can make them easier to clean and reuse, although their overall durability may not match that of needle felt variants. So, how do you decide which filter bag is right for your needs? If your operation involves filtering fine particles and requires high filtration efficiency, the polyester needle felt filter bag is likely the better choice. Its enhanced structure ensures that even the smallest particles are captured, reducing the risk of contamination and improving product quality. On the other hand, if your primary concern is filtering out larger particles and you’re working within a tighter budget, the polyester felt filter bag might be more appropriate. Its simpler design is sufficient for less demanding applications and can offer significant cost savings. Ultimately, understanding the material and structural differences between these two types of filter bags is key to making an informed decision. By considering the specific needs of your industrial process, you can select the filter bag that offers the best balance of performance, durability, and cost-effectiveness.

The Needle-Punching Advantage

The needle-punching process used in creating polyester needle felt filter bags is a game-changer. It involves thousands of barbed needles that pierce and entangle the polyester fibers, creating a complex, three-dimensional matrix. This structure is not only robust but also highly efficient at capturing particles. The interlocking fibers form a tight network that can trap even microscopic particles, ensuring cleaner air or liquid output. The mechanical stability provided by this process means the filter bags can withstand the rigors of continuous use without compromising on performance. For industries where precision filtration is paramount, such as pharmaceuticals or food processing, the needle-punching technique offers unmatched reliability. For specialized high-temperature filtration needs, consider our non-woven polyester felt solution.

Simplicity and Cost-Effectiveness of Polyester Felt

Polyester felt filter bags, while simpler in construction, offer their own set of benefits. Made by bonding polyester fibers together, these bags have a looser structure that is adequate for filtering larger particles. This simplicity translates to lower production costs, making them an attractive option for budget-conscious operations. Additionally, their straightforward design can facilitate easier maintenance and cleaning. For applications like waste management or basic dust collection, where fine particle filtration is not a priority, polyester felt filter bags provide a practical and economical solution. If you’re looking for a versatile felt filter solution, check out our high-performance felt filter.

Filter Efficiency & Cost Optimization: Real-World Case Studies on Polyester Needle Felt vs. Polyester Felt Filter Bags

When it comes to industrial filtration, the choice between polyester needle felt filter bags and polyester felt filter bags isn’t just about picking a product—it’s about optimizing your entire filtration process for efficiency and cost-effectiveness. Let’s dive into some real-world case studies to see how these two types of filter bags stack up in different industrial environments. First up, consider a cement manufacturing plant. Cement production involves a lot of dust and particulate matter, which can clog filters quickly. In this scenario, polyester needle felt filter bags shine due to their needle-punched structure. The needle felting process creates a three-dimensional matrix that traps particles more effectively than the flat, woven structure of polyester felt filter bags. As a result, the cement plant saw a 20% increase in filtration efficiency when switching to needle felt bags, leading to fewer downtimes for filter cleaning and replacement. But what about cost? Initially, polyester needle felt filter bags might seem pricier. However, when you factor in the longer lifespan and reduced maintenance costs, the total cost of ownership (TCO) often tips in favor of needle felt. In the cement plant example, despite the higher upfront cost, the needle felt bags lasted 30% longer than their polyester felt counterparts, resulting in a 15% lower TCO over a year. Now, let’s shift gears to a chemical processing facility. Here, the filtration needs are different. Chemicals can be corrosive, and the filters must withstand harsh conditions. Polyester felt filter bags, with their simpler structure, can sometimes be more resistant to certain chemicals, especially when treated with specific coatings. For those seeking high-temperature-resistant solutions, our high-temperature polyester felt filtration offers tailored performance. In one case, a chemical plant opted for polyester felt bags after finding that needle felt bags, while efficient, degraded faster under their specific chemical exposure. The key takeaway? It’s not just about efficiency; it’s about matching the filter material to your specific industrial environment. But don’t just take our word for it. Let’s look at the numbers. A comprehensive study comparing both types of filter bags across various industries found that, on average, polyester needle felt filter bags offered a 10-25% higher filtration efficiency. However, in environments with high chemical exposure or where the cost of downtime is exceptionally high, polyester felt filter bags could be the more economical choice due to their potentially lower replacement frequency. So, how do you decide? Start by assessing your industrial environment. What kind of particulates are you dealing with? Are there any corrosive substances? What’s the cost of downtime for your operation? Once you have a clear picture, you can weigh the benefits of higher efficiency against the potential savings from reduced maintenance and replacement costs. Remember, the goal is to find the sweet spot where filtration efficiency meets cost optimization. It’s not about choosing the ‘best’ filter bag in a vacuum; it’s about selecting the right one for your specific needs. And if you’re still unsure, don’t hesitate to reach out to filtration experts. They can provide tailored advice based on your industry, operational scale, and budget constraints. In conclusion, the choice between polyester needle felt filter bags and polyester felt filter bags is a nuanced one. It requires a deep understanding of your industrial processes, the nature of the particulates you’re dealing with, and the economic implications of your filtration choices. By considering real-world case studies and conducting a thorough cost-benefit analysis, you can make an informed decision that enhances your filtration efficiency and reduces your overall costs.

Cement Plant Case Study: Efficiency Gains with Needle Felt

In a cement manufacturing plant, the switch to polyester needle felt filter bags resulted in a 20% increase in filtration efficiency. The needle-punched structure of these bags trapped particles more effectively, reducing downtimes for filter cleaning and replacement. Despite a higher initial cost, the longer lifespan and reduced maintenance needs led to a 15% lower total cost of ownership over a year. For more information on high-efficiency solutions, check out our high-efficiency polyester felt filter bags.

Chemical Plant Case Study: Chemical Resistance Matters

A chemical processing facility found that polyester felt filter bags, when treated with specific coatings, were more resistant to certain chemicals compared to polyester needle felt bags. In this environment, the simpler structure of polyester felt bags proved advantageous, leading to a potentially lower replacement frequency and cost savings. For tailored liquid filtration solutions, explore our polyester felt filter bag for liquid filtration.

Comprehensive Study: Balancing Efficiency and Cost

A study comparing both types of filter bags across industries revealed that polyester needle felt bags offered 10-25% higher filtration efficiency on average. However, in environments with high chemical exposure or costly downtimes, polyester felt bags could be more economical due to reduced replacement needs.

Durability, Maintenance, and Applicability: A Deep Dive into Polyester Needle Felt vs. Polyester Felt Filter Bags

When it comes to industrial filtration, the longevity and upkeep of filter bags can significantly impact your operational efficiency and bottom line. So, how do polyester needle felt filter bags and polyester felt filter bags stack up in terms of durability, maintenance, and applicability? Let’s break it down. First off, durability is a key factor that directly influences how often you’ll need to replace your filter bags. Polyester needle felt filter bags, with their intricate needle-punched structure, tend to be more robust and resistant to wear and tear compared to their simpler polyester felt counterparts. This enhanced durability means fewer replacements over time, which translates to cost savings and less downtime for your filtration system. But wait, there’s more to it than just durability. Maintenance costs also play a crucial role in the overall lifecycle cost of your filter bags. Polyester needle felt bags, due to their superior durability, generally require less frequent maintenance. They can withstand harsher operating conditions without degrading as quickly, reducing the need for constant cleaning or repairs. On the other hand, polyester felt bags, while more economical upfront, might necessitate more frequent maintenance to keep them performing at their best. Now, let’s talk about applicability. Not all industrial applications are created equal, and neither are filter bags. Polyester needle felt filter bags excel in environments where high filtration efficiency and durability are paramount. Think of industries like cement production, steel manufacturing, or waste incineration, where the filtration system is subjected to extreme temperatures, abrasive particles, and corrosive gases. In these scenarios, the needle-punched structure of polyester needle felt bags provides a reliable barrier against contaminants, ensuring consistent air quality and system performance. Conversely, polyester felt filter bags might be more suitable for less demanding applications. If your industrial process involves relatively clean air streams or lower temperatures, a polyester felt bag could be a cost-effective choice. They’re easier to produce and often come at a lower price point, making them attractive for budget-conscious operations. However, it’s essential to weigh the initial cost savings against the potential for increased maintenance and shorter lifespan. Ultimately, the choice between polyester needle felt and polyester felt filter bags boils down to your specific industrial needs. Are you looking for long-term durability and low maintenance in a high-stress environment? Go for the needle felt option. Or, are you operating in a milder setting where cost efficiency is key? Then, a polyester felt bag might be the way to go. Remember, selecting the right filter bag isn’t just about the upfront cost. It’s about understanding how durability, maintenance, and applicability intersect to impact your overall operational efficiency. By considering these factors, you can make an informed decision that ensures your filtration system runs smoothly, efficiently, and cost-effectively for years to come.

Durability: The Backbone of Filter Bag Performance

Durability isn’t just a nice-to-have feature; it’s the backbone of any reliable filter bag. Polyester needle felt bags, with their needle-punched fibers, create a dense, three-dimensional matrix that’s highly resistant to abrasion, punctures, and chemical degradation. This means they can withstand the rigors of continuous operation in harsh industrial environments without compromising performance. In contrast, polyester felt bags, while still durable, lack the same level of structural integrity. Their simpler construction makes them more susceptible to wear and tear, especially in applications involving high velocities, heavy particulate loads, or corrosive substances. So, if you’re operating in an environment where durability is non-negotiable, polyester needle felt bags are the clear winner.

Maintenance: Keeping Your Filtration System Running Smoothly

Maintenance is another critical aspect to consider when choosing between polyester needle felt and polyester felt filter bags. Polyester needle felt bags, due to their superior durability, generally require less frequent maintenance. They can handle higher dust loads and more aggressive cleaning cycles without degrading, reducing the need for constant attention. Polyester felt bags, however, might need more regular cleaning and inspection to maintain optimal performance. This is especially true in applications where the air stream contains sticky or oily particulates that can clog the filter media. By choosing a more durable option like polyester needle felt, you can minimize maintenance downtime and keep your filtration system running at peak efficiency.

Applicability: Matching Filter Bags to Your Industrial Needs

Applicability is all about finding the right filter bag for your specific industrial application. Polyester needle felt filter bags shine in high-stress environments where filtration efficiency and durability are paramount. They’re ideal for industries like power generation, chemical processing, and metal smelting, where the filtration system must handle extreme temperatures, abrasive particles, and corrosive gases. On the other hand, polyester felt filter bags might be more suitable for less demanding applications, such as food processing, pharmaceuticals, or general ventilation systems. In these settings, the air stream is relatively clean, and the operating conditions are milder, making a simpler, more cost-effective filter bag a viable option. For more details on polyester felt filter bags’ high-efficiency liquid filtration solutions, you can explore our product page.

Navigating the world of polyester needle felt filter bags vs polyester felt filter bags can seem daunting, but armed with the insights from this comparison, you’re now better equipped to choose the right fit for your industrial filtration needs. Remember, the right filter bag not only boosts efficiency but also cuts down on long-term costs. Have more questions or need tailored advice? Our expert team is just a click away, ready to assist you in optimizing your filtration system. So, what’s your next move in enhancing your industrial setup?