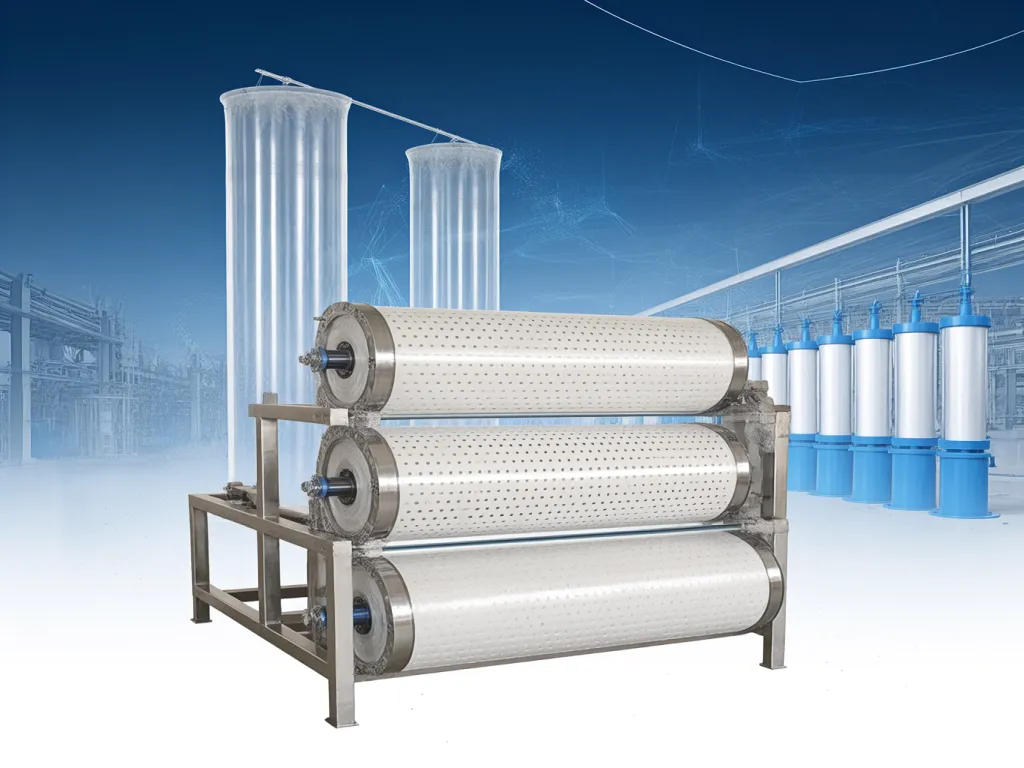

Polyester Felt Filter Bags: Thrive in Harsh Industrial Conditions

When it comes to industrial filtration, not all filter bags are created equal. Especially in harsh environments where extreme temperatures, abrasive particles, and chemical exposure are daily challenges, choosing the right filter bag is crucial. Enter the polyester felt filter bag for harsh industrial environments—a robust solution designed to withstand the toughest conditions while maintaining peak performance. But what makes these filter bags stand out? Let’s dive into the material, efficiency, and temperature resilience that set them apart.

Material Durability Analysis: Exploring the Wear – Resistance, Tear – Resistance, and Long – Term Stability of Different Polyester Fiber Materials

When it comes to polyester felt filter bags for harsh industrial environments, understanding the material durability is absolutely crucial. After all, these filter bags are constantly exposed to a variety of challenging conditions, from abrasive particles to high – stress mechanical forces. So, let’s dive deep into the world of polyester fiber materials and analyze their wear – resistance, tear – resistance, and long – term stability.

First off, let’s talk about wear – resistance. In industrial settings, polyester felt filter bags often come into contact with rough and abrasive substances. For example, in a cement plant, the filter bags have to deal with fine but extremely abrasive cement dust. Different types of polyester fibers react differently to this kind of wear. Some polyester fibers are treated with special coatings that act as a protective layer. These coatings can significantly reduce the friction between the fiber and the abrasive particles, thus extending the lifespan of the filter bag. Imagine a filter bag without such a coating; over time, the fibers would gradually wear down, leading to holes and a decrease in filtering efficiency. But with a proper coating, the bag can withstand the abrasive action for a much longer period, ensuring consistent performance.

Now, onto tear – resistance. Industrial processes can generate sudden and intense forces that could potentially tear the filter bag. Take a steel – making factory, for instance. The rapid movement of materials and the high – pressure environment can create stress points on the filter bag. Polyester fibers with high tensile strength are essential here. These fibers can resist the pulling and stretching forces without breaking. Some polyester materials are also woven in a specific pattern that enhances their tear – resistance. For example, a cross – woven structure distributes the stress evenly across the fibers, preventing a single point from becoming a weak spot that could lead to a tear.

Long – term stability is another key factor. In harsh industrial environments, the filter bags are exposed to not just physical stress but also chemical and thermal stress. Chemicals in the industrial air can react with the polyester fibers over time. For instance, in a chemical plant, there might be acidic or alkaline vapors that can degrade the fibers. Polyester materials that are chemically resistant are highly desirable. They can maintain their structural integrity even in the presence of such chemicals. Additionally, temperature fluctuations can also affect the long – term stability of the filter bags. Some polyester fibers are engineered to withstand a wide range of temperatures. Whether it’s the extreme cold of a refrigeration plant or the high heat of a foundry, these fibers can remain stable, ensuring that the filter bag continues to function effectively over its lifespan.

So, how do you know which polyester fiber material is the best for your specific industrial environment? Well, it’s not a one – size – fits – all situation. You need to consider the nature of the substances your filter bag will be exposed to, the level of mechanical stress it will face, and the chemical and thermal conditions in your workplace. By carefully evaluating these factors, you can select a polyester felt filter bag that offers the optimal combination of wear – resistance, tear – resistance, and long – term stability for your harsh industrial environment.

Coating Technologies for Enhanced Wear – Resistance

Coating technologies play a vital role in improving the wear – resistance of polyester fibers. There are various types of coatings available, each with its own unique properties. Some coatings are made from polymers that have excellent lubricating properties. These polymers form a thin film on the surface of the polyester fibers, reducing the friction coefficient. This means that when abrasive particles come into contact with the fibers, they slide over the coating instead of grinding against the fibers. Other coatings are ceramic – based. Ceramic coatings are extremely hard and can resist even the most abrasive substances. They create a tough barrier that protects the underlying polyester fibers. However, ceramic coatings can be more expensive and may require special application techniques. But in the long run, the investment in a high – quality coating can pay off by significantly extending the lifespan of the polyester felt filter bag.

Woven Patterns and Tear – Resistance

The woven pattern of polyester fibers has a direct impact on their tear – resistance. As mentioned earlier, a cross – woven structure is highly effective in distributing stress. In a cross – woven pattern, the fibers are woven at right angles to each other. This creates a strong and stable fabric. When a force is applied to the fabric, the stress is spread across multiple fibers, preventing any single fiber from being overstressed. Another woven pattern is the plain weave. Although it is simpler than the cross – weave, it still offers good tear – resistance. In a plain weave, the fibers alternate over and under each other in a regular pattern. This creates a balanced fabric that can resist tearing in multiple directions. Some manufacturers also use a combination of different woven patterns to achieve the best possible tear – resistance for their polyester felt filter bags.

Chemical and Thermal Stability of Polyester Fibers

Chemical and thermal stability are essential for polyester fibers in harsh industrial environments. To ensure chemical stability, manufacturers often use polyester materials that have been modified at the molecular level. These modifications can introduce chemical groups that are resistant to acids, bases, and other chemicals commonly found in industrial settings. For example, some polyester fibers are treated with fluorine – containing compounds, which give them excellent chemical resistance. In terms of thermal stability, polyester fibers can be engineered to have different melting points. High – temperature polyester fibers can withstand temperatures above 200°C, making them suitable for applications in high – heat environments such as power plants and foundries. On the other hand, low – temperature polyester fibers are designed to remain flexible and stable in cold conditions, which is important for industries like refrigeration and food processing.

Filter Efficiency Evaluation: Comparing the Performance of Polyester Felt Filter Bags with Different Apertures and Thicknesses

When it comes to industrial filtration, the devil is often in the details—especially when you’re dealing with harsh environments where dust, particulates, and even microscopic contaminants can wreak havoc on machinery and air quality. One of the most critical factors in choosing the right polyester felt filter bag for your needs is understanding how different apertures (pore sizes) and thicknesses impact overall filtration efficiency. Let’s dive deep into this topic, exploring how these variables affect the bag’s ability to capture tiny particles and improve air quality in demanding industrial settings.

First off, let’s talk about aperture size. Imagine your filter bag as a sieve; the smaller the holes (or pores), the finer the particles it can trap. Polyester felt filter bags come in a range of aperture sizes, typically measured in microns (µm). A 1-micron filter bag, for instance, is designed to capture particles as small as one-millionth of a meter—that’s incredibly fine! On the other hand, a 10-micron bag will let through larger particles but may offer better airflow and lower pressure drop, which can be crucial in high-volume applications. For industrial applications requiring high-efficiency filtration, consider exploring our polyester felt filter bag solutions.

But here’s the kicker: smaller isn’t always better. While a finer aperture captures more particles, it also requires more energy to push air through, potentially increasing operational costs. Moreover, in environments with high concentrations of large particles, a very fine filter might clog quickly, leading to frequent replacements and downtime. That’s why finding the sweet spot—the aperture size that balances capture efficiency with airflow and longevity—is key.

Now, let’s shift gears to thickness. Thicker filter bags generally mean more surface area for particles to adhere to, which can enhance overall filtration capacity. They also tend to be more durable, resisting wear and tear from abrasive particles. However, increased thickness can also lead to higher pressure drops across the filter, requiring more robust fans or blowers to maintain adequate airflow. This trade-off between capacity and pressure drop is something every industrial operator must consider carefully.

So, how do you choose the right combination of aperture and thickness for your polyester felt filter bag? The answer lies in understanding your specific industrial environment. Are you dealing with predominantly fine dust, like in pharmaceutical manufacturing, or larger, heavier particles, such as in metalworking? Is air quality a top priority due to regulatory requirements or worker health concerns? Answering these questions will help you narrow down your options.

Let’s look at a couple of real-world scenarios. In a cement plant, where large quantities of coarse dust are generated, a thicker filter bag with a moderately sized aperture (say, 5-10 microns) might be ideal. It can handle the volume of particles without clogging too quickly, while still capturing a significant portion of the dust. Conversely, in a semiconductor fabrication facility, where even the tiniest contaminants can ruin delicate components, a thinner but finer (1-3 micron) filter bag would be necessary to achieve the required cleanliness levels.

It’s also worth mentioning that advancements in filter media technology have led to the development of graded-density filter bags. These bags feature a layered structure where the outer layers have larger pores to capture coarse particles, while the inner layers have finer pores for microscopic contaminants. This design maximizes both capacity and efficiency, making it a popular choice in many industrial applications.

In conclusion, selecting the right polyester felt filter bag for harsh industrial environments isn’t a one-size-fits-all proposition. It requires a thoughtful analysis of your specific needs, balancing aperture size, thickness, and other factors like temperature resistance and chemical compatibility. By doing so, you can ensure that your filtration system not only captures micro-particles effectively but also operates efficiently, safely, and cost-effectively over the long haul. Have you considered how these variables might play out in your own industrial setting? Let’s discuss further and find the perfect filtration solution for you!

The Impact of Aperture Size on Particle Capture

Aperture size is a fundamental aspect of filter bag performance. Smaller apertures enhance the bag’s ability to capture fine particles, crucial in industries where even minute contaminants can cause significant problems. However, as aperture size decreases, so does airflow, potentially increasing energy consumption and operational costs. It’s a delicate balance: too fine, and you risk clogging; too coarse, and you might not meet air quality standards. Understanding your specific particle size distribution is essential in selecting the optimal aperture size for your polyester felt filter bag. For applications involving high-temperature environments, consider our high-temperature resistant polyester felt filter bags.

Thickness: Balancing Capacity and Pressure Drop

Thicker filter bags offer increased surface area, which can enhance filtration capacity and durability. They’re particularly useful in environments with high particle loads, as they can trap more contaminants before needing replacement. However, the added thickness also increases pressure drop across the filter, requiring more powerful airflow systems to maintain performance. This trade-off necessitates a careful evaluation of your industrial processes and air quality requirements to determine the most suitable thickness for your polyester felt filter bag.

Graded-Density Filter Bags: A Smart Solution

Graded-density filter bags represent a significant advancement in filtration technology. By incorporating layers with varying pore sizes, these bags can efficiently capture both coarse and fine particles. The outer layers act as a pre-filter, trapping larger contaminants and extending the life of the inner, finer layers. This design not only maximizes filtration efficiency but also reduces the frequency of filter replacements, lowering overall maintenance costs. If you’re looking for a versatile and cost-effective solution for your industrial filtration needs, graded-density polyester felt filter bags are definitely worth considering. For efficient liquid filtration, check out our high-efficiency liquid filtration solutions.

Temperature Tolerance Range Considerations: Investigating Performance Changes of Polyester Felt Filter Bags in High and Low Temperature Environments

When it comes to industrial filtration, the ability of polyester felt filter bags to withstand extreme temperatures is a game-changer. Imagine your factory operates in a region where summer temperatures soar, or winter brings bone-chilling cold. In such harsh industrial environments, the performance of your filter bags can’t just be good; it has to be exceptional. So, how exactly do polyester felt filter bags fare under these temperature extremes?

Let’s start with the high-temperature scenario. Polyester fibers, the backbone of these filter bags, are engineered to resist thermal degradation. But what does that really mean for you? Well, when the mercury rises, say above 200°C (392°F), some materials might start to break down, losing their structural integrity and, consequently, their filtering efficiency. Not polyester felt. It maintains its shape and filtering prowess even in these scorching conditions. This is crucial because, in industries like steel manufacturing or cement production, the exhaust gases can reach temperatures that would make lesser materials crumble.

But it’s not just about surviving the heat; it’s about thriving. Polyester felt filter bags are designed to keep their pores open and functional, ensuring that even as the temperature climbs, the airflow remains steady, and the filtration efficiency stays high. This means fewer clogs, less downtime for maintenance, and ultimately, a more efficient operation.

Now, let’s flip the script and talk about the cold. When temperatures plummet, materials can become brittle, leading to cracks and tears. Again, polyester felt shines. Its inherent flexibility allows it to withstand freezing temperatures without becoming brittle. This is particularly important in industries like food processing or pharmaceuticals, where clean rooms and controlled environments are the norm, but the external conditions can still be harsh.

But how does this translate to real-world performance? Let’s consider a case study. A European chemical plant, located in a region known for its frigid winters, switched to polyester felt filter bags. Before the switch, they were experiencing frequent filter bag failures during the winter months, leading to costly downtime and reduced production. After making the change, not only did the filter bags survive the winter, but they also maintained their filtration efficiency, resulting in a significant boost in overall plant productivity.

So, what’s the secret sauce? It’s all in the material science. Polyester fibers are treated and woven in a way that enhances their thermal stability. This means they can expand and contract with temperature changes without losing their structural integrity. It’s like having a filter bag that can ‘breathe’ with the environment, ensuring optimal performance regardless of the temperature outside.

But don’t just take our word for it. The data speaks for itself. Studies have shown that polyester felt filter bags can maintain their filtration efficiency at temperatures ranging from -40°C (-40°F) to over 200°C (392°F). This wide temperature tolerance range makes them a versatile choice for industries operating in diverse climates.

In conclusion, when you’re selecting a filter bag for your industrial operation, don’t overlook the importance of temperature tolerance. Polyester felt filter bags offer a robust solution that can withstand the rigors of both high and low temperature environments, ensuring your filtration system remains efficient and reliable, year-round.

High-Temperature Performance: Staying Cool Under Pressure

In high-temperature environments, the performance of polyester felt filter bags is nothing short of remarkable. The fibers are engineered to resist thermal degradation, maintaining their structural integrity even when exposed to temperatures exceeding 200°C (392°F). This is crucial in industries where exhaust gases can reach extreme temperatures, such as steel manufacturing or cement production. The ability of polyester felt to keep its pores open and functional ensures steady airflow and high filtration efficiency, reducing clogs and maintenance downtime.

Low-Temperature Resilience: Flexibility in the Cold

When temperatures drop, polyester felt filter bags demonstrate their resilience. Unlike some materials that become brittle in the cold, polyester retains its flexibility, preventing cracks and tears. This is particularly valuable in industries like food processing or pharmaceuticals, where clean rooms and controlled environments are essential, but external conditions can still be harsh. The material’s ability to withstand freezing temperatures without losing performance ensures reliable filtration even in the coldest climates.

Real-World Case Study: A Winter Success Story

A European chemical plant, located in a region with frigid winters, provides a compelling case study. Before switching to polyester felt filter bags, the plant experienced frequent filter bag failures during winter, leading to costly downtime. After the change, the filter bags not only survived the winter but also maintained their filtration efficiency, resulting in a significant boost in plant productivity. This real-world example highlights the practical benefits of choosing polyester felt for extreme temperature environments.

Selecting the ideal polyester felt filter bag for harsh industrial environments isn’t just about durability; it’s about ensuring your operations run smoothly, efficiently, and sustainably. By weighing material durability, filtration efficiency, and temperature tolerance, you’re equipped to make an informed choice. Remember, the right filter bag can transform your industrial processes, cutting costs and boosting productivity. So, why wait? Explore our range of polyester felt filter bags today and take the first step toward a cleaner, more efficient industrial future. What challenges will your next filter bag help you overcome?