Polyester Felt Filter Bag: Industrial Filtration Game-Changer

In the realm of industrial filtration, efficiency is king. Whether you’re dealing with dust-laden air or complex liquid streams, the right filter bag can make all the difference. Enter the polyester felt filter bag in industrial filtration—a versatile, durable solution that’s transforming how we approach clean processes. But what makes this filter bag stand out? How can you ensure you’re choosing the best one for your specific needs? Let’s dive in and uncover the secrets to selecting the perfect polyester felt filter bag.

How Filter Efficiency Relates to Polyester Felt Filter Bag Material and Structure: Choosing the Right Bag for Your Application

When it comes to industrial filtration, the efficiency of your system often hinges on one crucial component: the filter bag. Specifically, polyester felt filter bags have become a go-to choice for many applications due to their versatility and performance. But why does material and structure matter so much? Let’s break it down and explore how to select the perfect polyester felt filter bag for your specific industrial needs.

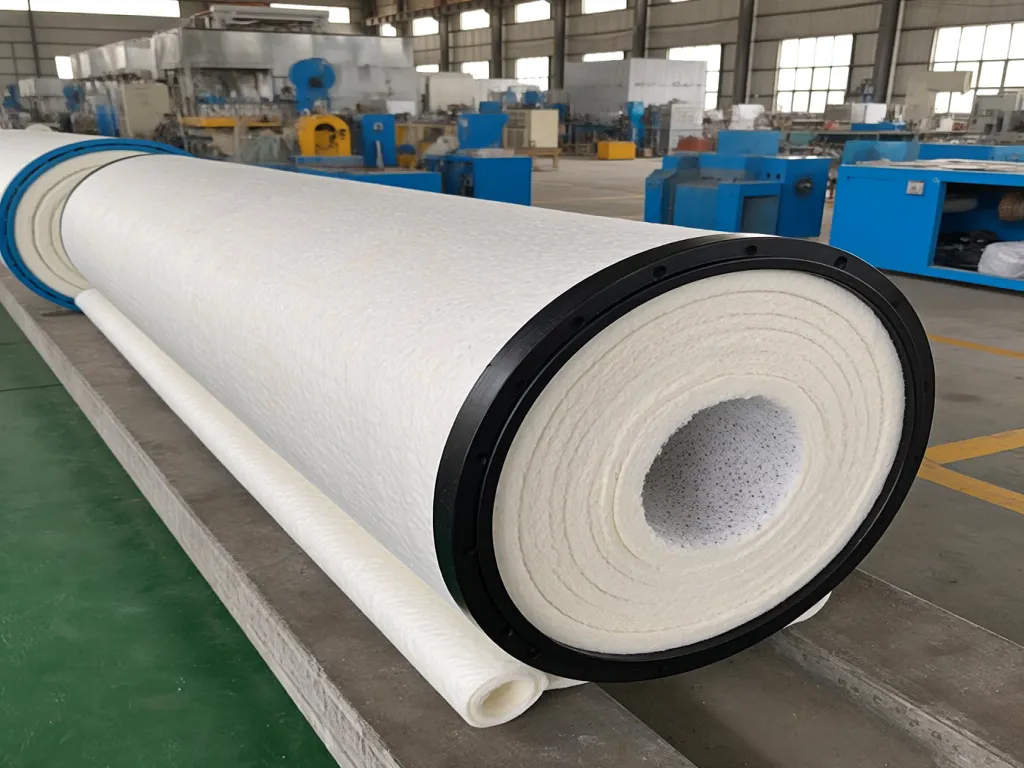

First, let’s talk about the material itself. Polyester felt is made from synthetic fibers that are woven or needled into a felt-like fabric. This material is prized for its durability, resistance to abrasion, and ability to handle a wide range of temperatures. But not all polyester felts are created equal. The quality of the fibers, the density of the weave, and the finishing treatments applied can all influence how well the filter bag performs in your system.

Now, onto structure. The design of a polyester felt filter bag can vary significantly. Some bags are surface-loaded, meaning they capture particles on the outer layer of the fabric. Others are depth-loaded, where particles are trapped throughout the thickness of the felt. Surface-loaded bags are great for applications with larger particles and lower dust loads, as they offer less resistance to airflow. Depth-loaded bags, on the other hand, excel in fine particle filtration and high dust load scenarios, thanks to their increased surface area and ability to trap particles deep within the felt.

So, how do you choose the right polyester felt filter bag for your application? It all starts with understanding your specific industrial needs. Are you dealing with coarse dust or fine particulates? Is your system operating at high temperatures or in a corrosive environment? These factors will guide your selection process.

For instance, if you’re filtering coarse dust in a relatively clean environment, a surface-loaded polyester felt bag with a looser weave might be sufficient. It’ll offer good airflow and easy cleaning, reducing downtime and maintenance costs. But if you’re dealing with fine particles or high dust loads, a depth-loaded bag with a tighter weave and possibly a PTFE membrane for enhanced particle release would be a better fit. This type of bag will provide superior filtration efficiency and longer service life, even in demanding conditions. For specialized needs, such as high-temperature resistance, consider our high-temperature-resistant polyester felt solution.

Another consideration is the operating temperature of your system. Polyester felt can typically handle temperatures up to around 130°C (266°F), but if your application requires higher temperatures, you might need to look for a specialized heat-resistant treatment or consider alternative materials. Similarly, if your system is exposed to chemicals or moisture, you’ll want to choose a polyester felt bag with the appropriate chemical resistance and possibly a hydrophobic finish to prevent clogging and maintain efficiency.

In summary, the relationship between filter efficiency and polyester felt filter bag material and structure is a nuanced one. By carefully considering your specific industrial needs—particle size, dust load, temperature, and chemical exposure—you can select a filter bag that not only meets but exceeds your expectations. And remember, the right filter bag isn’t just about efficiency; it’s also about reducing downtime, lowering maintenance costs, and ensuring the longevity of your filtration system.

Material Quality Matters

The quality of polyester fibers used in the filter bag can greatly affect its performance. High-quality fibers are more durable and resistant to abrasion, which means they can withstand the rigors of industrial filtration without breaking down prematurely. Additionally, the density of the weave or needling process influences the bag’s ability to capture particles. A tighter weave provides better filtration for fine particles, while a looser weave allows for easier airflow and is suitable for coarser dust. For applications requiring woven solutions, explore our woven fiberglass dust filter felt cloth for enhanced efficiency.

Structure Design for Specific Needs

The structure of the polyester felt filter bag, whether surface-loaded or depth-loaded, should be chosen based on the particle size and dust load of your application. Surface-loaded bags are ideal for applications with larger particles and lower dust loads, as they offer less resistance to airflow and are easier to clean. Depth-loaded bags, with their increased surface area and ability to trap particles throughout the felt, are better suited for fine particle filtration and high dust load scenarios.

Temperature and Chemical Resistance

Operating temperature and chemical exposure are critical factors in selecting the right polyester felt filter bag. While standard polyester felt can handle temperatures up to around 130°C (266°F), specialized treatments can enhance its heat resistance for higher-temperature applications. Similarly, choosing a bag with the appropriate chemical resistance ensures it won’t degrade or clog when exposed to corrosive substances, maintaining efficiency and prolonging service life.

How Durability of Polyester Felt Filter Bags Reduces Replacement Frequency

When it comes to industrial filtration, the durability of polyester felt filter bags isn’t just a nice-to-have feature—it’s a game-changer. Imagine this: you’re running a manufacturing plant, and your filtration system is the backbone of your operations. Every time a filter bag wears out and needs replacing, it’s not just a minor inconvenience. It’s downtime, it’s extra costs, and it’s a potential hit to your productivity. So, how exactly does the durability of these filter bags impact your replacement frequency? Let’s dive in.

First off, durability directly correlates with the lifespan of your filter bags. A more durable bag means it can withstand the rigors of your industrial environment for longer periods. This translates to fewer replacements over time. Think about it—if a filter bag can last twice as long as its less durable counterpart, you’re effectively cutting your replacement costs in half. That’s significant savings, especially when you’re dealing with large-scale operations where hundreds or even thousands of filter bags are in use.

But durability isn’t just about longevity; it’s also about performance consistency. A durable filter bag maintains its filtration efficiency over time, even as it’s subjected to harsh conditions like high temperatures, chemical exposure, or abrasive particles. This means you’re not just saving money on replacements; you’re also ensuring that your filtration system is always operating at peak performance. After all, what good is a filter bag that lasts a long time if it can’t do its job effectively? For those seeking high-efficiency solutions, exploring our range of high-efficiency felt filters could be a great starting point.

Now, you might be wondering, how can you ensure that you’re choosing the most durable polyester felt filter bags for your specific needs? The answer lies in understanding the key factors that contribute to durability and how they relate to your industrial processes.

Material Selection for Enhanced Durability

The foundation of a durable polyester felt filter bag starts with the material itself. Polyester, as a synthetic fiber, offers several advantages over natural fibers like cotton or wool. For starters, polyester is inherently more resistant to abrasion, which means it can withstand the wear and tear of constant particle contact without breaking down as quickly. This is crucial in industrial settings where the filter bags are constantly bombarded with abrasive materials.

But not all polyester is created equal. The quality of the polyester fibers, their thickness, and how they’re woven or felted together can all impact the durability of the final product. For instance, a filter bag made from high-grade, thick polyester fibers that are tightly felted will generally be more durable than one made from thinner, lower-grade fibers with a looser felt structure.

Another material consideration is the addition of special coatings or treatments. Some polyester felt filter bags are treated with chemicals that enhance their resistance to specific substances, like oils or chemicals. These treatments can significantly extend the lifespan of the filter bag in environments where these substances are present.

Craftsmanship and Process Optimization

While material selection is crucial, the way a filter bag is crafted also plays a significant role in its durability. The manufacturing process, from weaving or felting the fibers to stitching the seams and attaching the hardware, must be optimized to ensure the highest quality product.

One key aspect of craftsmanship is the stitching. A filter bag with weak or poorly stitched seams is a recipe for disaster. The seams are the weakest points of the bag, and if they fail, the entire bag is compromised. That’s why it’s essential to choose filter bags that are stitched with high-quality thread and in a pattern that distributes the stress evenly across the seam.

Process optimization also involves ensuring that the filter bags are made to precise specifications. This means that the dimensions, pore size, and other critical features are consistent from bag to bag. Inconsistent bags can lead to uneven wear and tear, reducing the overall lifespan of the filtration system.

Additionally, some manufacturers employ advanced technologies like laser cutting or ultrasonic welding to create filter bags with superior durability. These methods can result in cleaner cuts, stronger seams, and a more uniform product overall. For more insights into high-performance solutions, consider reviewing our high-performance felt filter offerings.

Real-World Durability: Case Studies and Industry Examples

To truly understand the impact of durability on replacement frequency, let’s look at some real-world examples. In a cement plant, for instance, the filtration system is subjected to extremely abrasive particles and high temperatures. A durable polyester felt filter bag, specifically designed for this harsh environment, can last significantly longer than a generic bag.

One case study highlighted how a cement plant switched to a higher-grade polyester felt filter bag with a special abrasion-resistant coating. The result? A 50% reduction in replacement frequency, leading to substantial cost savings and improved operational efficiency. The plant was able to run its filtration system for longer periods without interruption, boosting productivity and reducing maintenance costs.

Similarly, in a chemical processing plant, where the filter bags are exposed to corrosive substances, choosing a polyester felt filter bag with a chemical-resistant treatment can make all the difference. These treated bags can withstand the harsh chemicals without degrading, extending their lifespan and reducing the need for frequent replacements.

These examples illustrate how material selection and process optimization can lead to more durable filter bags, which in turn reduce replacement frequency and improve overall filtration system performance. For further exploration of high-efficiency solutions tailored to industrial needs, our high-efficiency industrial filtration solutions provide valuable insights.

The Critical Role of Chemical Stability in Industrial Filtration

When it comes to industrial filtration, the chemical stability of your filter bags isn’t just a nice-to-have feature—it’s a must-have. Imagine you’re dealing with aggressive chemicals, high temperatures, or corrosive environments. In such scenarios, a filter bag that can’t withstand these conditions will quickly degrade, leading to frequent replacements, increased downtime, and ultimately, higher operational costs. Not to mention the potential safety hazards that come with filter bag failure.

So, why is chemical stability so crucial? Let’s break it down. First, a chemically stable polyester felt filter bag will maintain its structural integrity even when exposed to harsh chemicals. This means it won’t break down, tear, or release harmful particles into your process stream. Second, it ensures consistent filtration performance over time. You won’t have to worry about fluctuations in efficiency or quality due to filter bag degradation.

Now, how do you go about selecting a polyester felt filter bag with high chemical stability? It all starts with understanding your process media. What chemicals are you filtering? Are they acidic, alkaline, or neutral? What’s the temperature range? Are there any solvents or oils present? Answering these questions will give you a clear picture of the chemical environment your filter bag will be operating in.

Once you have a good grasp of your process media, you can start looking for filter bags that are specifically designed to handle those conditions. For instance, if you’re dealing with highly acidic environments, you’ll want a filter bag that’s resistant to acid corrosion. Similarly, if your process involves high temperatures, you’ll need a filter bag that can withstand those temperatures without melting or degrading.

But here’s the thing: not all polyester felt filter bags are created equal. Some may claim to be chemically stable, but in reality, they may only be suitable for mild conditions. That’s why it’s essential to do your homework. Look for filter bags that have been tested and certified for chemical stability under the specific conditions you’ll be using them in. Don’t be afraid to ask the manufacturer for test data or case studies that demonstrate the filter bag’s performance in similar environments.

Another factor to consider is the construction of the filter bag. Even if the material itself is chemically stable, poor construction can lead to premature failure. Look for filter bags with reinforced seams, sturdy attachment mechanisms, and a consistent, dense felt structure. These features will ensure that your filter bag can handle the rigors of your industrial filtration process without compromising on performance.

In summary, chemical stability is a non-negotiable factor when selecting polyester felt filter bags for industrial filtration. By understanding your process media and choosing a filter bag that’s specifically designed to handle those conditions, you can ensure consistent, reliable filtration performance while minimizing downtime and operational costs. So, the next time you’re in the market for filter bags, remember: chemical stability isn’t just a feature—it’s the foundation of a successful industrial filtration process.

Understanding Process Media for Optimal Filter Bag Selection

Let’s dive deeper into understanding your process media. This step is crucial because it lays the groundwork for selecting the right polyester felt filter bag. Start by listing all the chemicals present in your process stream. Are they organic or inorganic? What’s their concentration? Next, consider the temperature range. Is it consistently high, or does it fluctuate? Also, think about any physical properties like viscosity or abrasiveness. All these factors will influence your filter bag selection.

For example, if you’re filtering a strong acid like sulfuric acid, you’ll need a filter bag made from a material that’s highly resistant to acid corrosion, such as certain types of polyester or even specialized coatings. On the other hand, if you’re dealing with a basic solution like sodium hydroxide, you’ll need a filter bag that can withstand alkaline conditions.

Don’t overlook the importance of temperature either. A filter bag that works well at room temperature might fail miserably at elevated temperatures. Look for filter bags that have been tested and proven to maintain their chemical stability across the entire temperature range of your process.

By taking the time to thoroughly understand your process media, you can narrow down your filter bag options to those that are truly suitable for your application. This will save you time, money, and headaches down the road.

The Role of Construction in Chemical Stability

We’ve talked about the importance of material selection, but let’s not forget about construction. Even the most chemically stable material can fail if the filter bag isn’t constructed properly. So, what should you look for in terms of construction?

First, check the seams. Are they reinforced? Do they use a strong, durable thread? Weak seams can lead to leaks or even complete bag failure. Next, look at the attachment mechanism. Is it secure? Will it hold up under the pressure of your filtration process? A loose or faulty attachment can cause the filter bag to detach from the filter housing, leading to process interruption and potential safety hazards.

Finally, consider the felt structure itself. Is it consistent and dense? A well-constructed felt will have a uniform thickness and density, ensuring even filtration and preventing particles from bypassing the filter bag. On the other hand, a poorly constructed felt might have thin spots or inconsistencies that compromise its chemical stability and filtration performance. For a high-efficiency industrial filtration solution, you may want to explore options like the felt filter which is designed with these considerations in mind.

In short, don’t overlook the importance of construction when selecting a polyester felt filter bag. A well-constructed filter bag will not only last longer but also perform better, giving you the peace of mind you need to focus on your core business operations.

Selecting the ideal polyester felt filter bag in industrial filtration isn’t just about ticking boxes; it’s about optimizing your entire filtration system for peak performance. By understanding the nuances of filter efficiency, durability, and chemical stability, you’re well-equipped to make an informed choice that boosts productivity and cuts costs. Remember, the right filter bag is an investment in your operation’s future. So, why wait? Take the leap, implement the insights from this guide, and watch your industrial filtration soar to new heights. Ready to transform your filtration setup? The journey starts now.