Master Paint Filter Bag Selection: Key Parameters Unveiled

In the fast-paced world of coating production, every detail matters—especially when it comes to choosing the right paint filter bag. Whether you’re a seasoned procurement pro or a production tech seeking efficiency, understanding the core parameters of paint filter bags is crucial. From filtering accuracy to material durability and flow rate, this guide dives deep into what makes a paint filter bag the perfect fit for your needs. Ready to unlock the secrets to seamless production? Let’s get started.

Filtration Accuracy: Analyzing Requirements for Different Coating Types and How to Choose the Right Grade Based on Production Needs

When it comes to selecting the right paint filter bag, filtration accuracy is a cornerstone parameter that can make or break your production process. But what exactly is filtration accuracy, and why does it matter so much for different coating types? Let’s break it down in a way that’s easy to digest. Filtration accuracy refers to the size of particles that a filter bag can effectively capture and retain. It’s measured in microns (µm), where a lower number means finer filtration. For example, a 5-micron filter bag will trap smaller particles than a 20-micron one. Now, why does this matter for your coatings? Different coatings have varying particle sizes and compositions. Water-based coatings, for instance, often contain smaller, more uniform particles compared to solvent-based or powder coatings. If you’re using a water-based coating, you might not need an ultra-fine filter like a 1-micron bag, which could clog quickly and reduce flow rates. Instead, a 5-10 micron bag might strike the perfect balance between efficiency and longevity. On the flip side, solvent-based coatings can have larger, more irregular particles. These might require a coarser filter initially, say 15-20 microns, to prevent premature clogging. But here’s the kicker: some solvent-based coatings also contain fine pigments that need finer filtration downstream. This is where a multi-stage filtration system with progressively finer bags comes into play. Powder coatings are a different beast altogether. They’re dry and can generate a lot of dust. For these, you’ll want a filter bag that can handle both the initial bulk dust and the finer particles that escape the first pass. A combination of a pre-filter (say, 30-50 microns) followed by a finer bag (5-10 microns) often works wonders. But how do you know which filtration grade is right for your specific production needs? Start by analyzing your coating’s particle size distribution. Most coating suppliers provide this data. If not, a simple sieve analysis can give you a rough idea. Next, consider your desired finish quality. Are you aiming for a smooth, glossy finish where every micron counts? Or is a more matte, textured look acceptable? The stricter your quality standards, the finer your filtration will need to be. Don’t forget about production volume. A high-volume line might tolerate slightly coarser filtration to maintain flow rates, while a low-volume, high-precision operation can afford finer filters. Here’s a pro tip: always err on the side of slightly finer filtration than you think you need. It’s easier to adjust your process if the filter is too fine (by increasing flow rates or using pre-filtration) than if it’s too coarse (resulting in quality issues that might require rework). Remember, choosing the right filtration accuracy isn’t just about the bag itself. It’s about how it fits into your entire production ecosystem. The right bag in the wrong system won’t perform optimally. So, take a holistic view of your coating process, from mixing to application, and choose a filtration grade that complements every stage. By now, you might be wondering, ‘But how do I balance all these factors?’ It’s a valid question. The answer lies in understanding that filtration accuracy is a dynamic parameter. What works today might need adjustment tomorrow as your coatings or production volumes change. That’s why flexibility in your filtration system is key. Look for filter bags that come in a range of accuracies and can be easily swapped out as needed. In the next section, we’ll dive into how material durability plays into this equation, but for now, let’s recap: filtration accuracy is your first line of defense against impurities in your coatings. Get it right, and you’ll see fewer defects, less waste, and happier customers. Get it wrong, and you might find yourself dealing with costly rework or, worse, lost business. So, take the time to analyze your coatings, understand your quality requirements, and choose a filtration grade that aligns with your production goals. Your bottom line will thank you for it.

Water-Based Coatings: Balancing Efficiency and Longevity

Water-based coatings are popular for their eco-friendliness and ease of cleanup. But when it comes to filtration, they demand a delicate balance. The particles in water-based coatings are often smaller and more uniform, meaning a very fine filter could clog rapidly. Imagine trying to pour a thick smoothie through a coffee filter – it’d be a slow, messy process. That’s why for water-based coatings, a 5-10 micron filter bag often hits the sweet spot. It’s fine enough to catch most impurities but not so fine that it chokes on the coating’s natural particles. This balance ensures smooth flow rates while maintaining high-quality output. But don’t just take my word for it. Test different filtration grades with your specific water-based coating. You might find that a slightly coarser or finer filter works better depending on your exact formulation and application method.

Solvent-Based Coatings: The Multi-Stage Approach

Solvent-based coatings bring their own set of challenges. Their particles can be larger and more irregular, requiring a different filtration strategy. Initially, you might use a coarser filter, say 15-20 microns, to handle the bulk of the particles. This prevents your system from getting overwhelmed right out of the gate. But here’s where it gets interesting. Many solvent-based coatings also contain fine pigments that need to be filtered out for a flawless finish. This is where a multi-stage filtration system shines. After the initial coarse filtration, a second, finer filter (5-10 microns) can catch those elusive fine particles. It’s like sifting flour – first, you remove the lumps with a coarse sieve, then you get the fine particles with a finer one. For more insights on optimizing multi-stage filtration systems, you can refer to industry-specific guides on filtration best practices. This approach ensures you’re not sacrificing flow rate for quality or vice versa.

Powder Coatings: Handling the Dusty Challenge

Powder coatings are a unique animal in the coating world. Being dry, they generate a significant amount of dust during application. This dust can vary in size, from large flakes to fine particles. For powder coatings, a single-stage filtration often isn’t enough. You’ll typically need a pre-filter to catch the bulk of the dust, say a 30-50 micron bag. This prevents your finer filters from clogging prematurely with large dust particles. After the pre-filter, a finer bag (5-10 microns) can capture the smaller particles that slip through. This two-stage approach ensures your system stays clean and efficient. But remember, powder coating systems often recirculate air, so your filtration needs to be top-notch to prevent dust from settling back onto your products. Think of it like vacuuming your house – you wouldn’t want to just move the dust around; you want to capture it effectively.

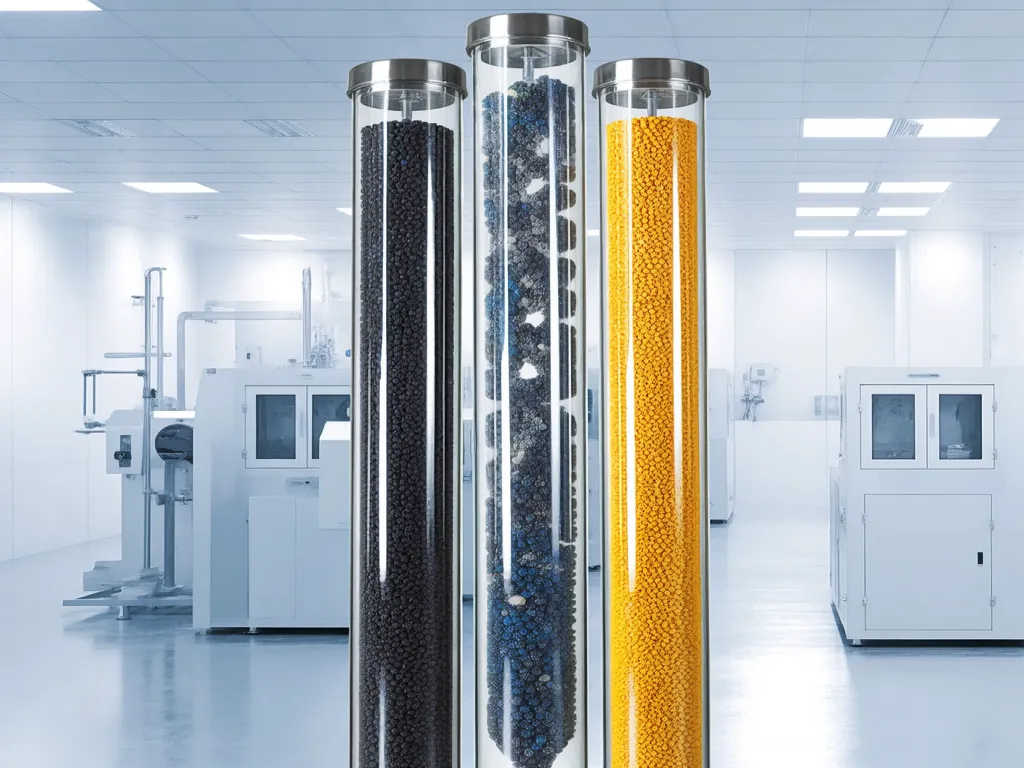

Material Durability: Comparing Polyester, Polypropylene, Nylon, and More for Paint Filter Bags

When it comes to choosing the right paint filter bag for your production line, material durability is a non-negotiable factor. After all, you want a filter bag that can withstand the rigors of your specific production environment without compromising performance. So, let’s dive into the world of materials and see how polyester, polypropylene, nylon, and others stack up against each other in terms of durability and suitability for different settings.

First up, polyester. This material is a favorite among many paint manufacturers due to its excellent resistance to abrasion and chemicals. Polyester paint filter bags can handle a wide range of temperatures, making them versatile for various production environments. Whether you’re dealing with high-temperature curing processes or cold storage conditions, polyester maintains its structural integrity. Plus, its resistance to moisture absorption ensures that your filter bag won’t become waterlogged and inefficient over time. For those interested in exploring a range of polyester options, our wholesale polyester pocket filter bags offer factory-direct prices and quality. But how does it fare in extremely corrosive environments? Well, while polyester is resistant to many chemicals, it’s not invincible. For highly acidic or alkaline conditions, you might want to consider alternatives.

Next on the list is polypropylene. This material is known for its chemical inertness, meaning it doesn’t react easily with most substances. That makes polypropylene paint filter bags a great choice for environments where chemical exposure is a constant concern. They’re also lightweight and have a low moisture absorption rate, which is beneficial for maintaining efficiency. However, polypropylene has a lower melting point compared to polyester, so it’s not the best option for high-temperature applications. If your production process involves heat curing at elevated temperatures, you might want to look elsewhere.

Now, let’s talk about nylon. Nylon paint filter bags are renowned for their strength and durability. They can withstand significant mechanical stress, making them ideal for heavy-duty applications. Nylon also has good resistance to abrasion and can handle a variety of chemicals, although not as extensively as polypropylene. One downside to nylon is its tendency to absorb moisture, which can lead to reduced efficiency over time if not properly managed. But in environments where mechanical strength is paramount, nylon shines.

But wait, there’s more to the story than just these three materials. What about other options like PTFE (Polytetrafluoroethylene) or fiberglass? PTFE is known for its exceptional chemical resistance and high-temperature tolerance. It’s practically inert to most chemicals, making it a top choice for highly corrosive environments. However, PTFE can be more expensive, so it’s often reserved for specialized applications. For those seeking PTFE-coated options, our wholesale PTFE-coated polyester dust filter bags provide a premium solution. Fiberglass, on the other hand, offers excellent heat resistance and is often used in high-temperature filtration processes. But it’s not as chemically resistant as PTFE and can be more brittle, requiring careful handling.

So, how do you decide which material is right for your production environment? It all comes down to understanding your specific needs. Are you dealing with high temperatures, corrosive chemicals, or heavy mechanical stress? By assessing these factors, you can narrow down your options and choose a paint filter bag material that will deliver the durability and performance you need. Remember, the right material can make all the difference in maintaining efficient production and ensuring high-quality output.

Polyester: The All-Rounder

Polyester paint filter bags are the go-to choice for many due to their balanced properties. They offer good resistance to abrasion, chemicals, and a wide temperature range. This makes them suitable for a variety of production environments, from moderate to high-temperature settings. For a comprehensive selection, consider our wholesale polyester dust collector filter bags, which are designed to meet diverse industrial needs. However, for extremely corrosive conditions, you might need to explore other options.

Polypropylene: Chemical Resistance Champion

If chemical exposure is a major concern in your production process, polypropylene paint filter bags are worth considering. Their chemical inertness ensures they won’t react with most substances, maintaining efficiency and longevity. Just keep in mind their lower melting point when dealing with high-temperature applications.

Nylon: Strength and Durability

For heavy-duty applications where mechanical strength is crucial, nylon paint filter bags are a solid choice. They can withstand significant stress and offer good resistance to abrasion. Be mindful of their moisture absorption tendency, though, and ensure proper management to maintain efficiency.

Specialized Materials: PTFE and Fiberglass

When standard materials won’t cut it, specialized options like PTFE and fiberglass come into play. PTFE offers unmatched chemical resistance and high-temperature tolerance, making it ideal for highly corrosive environments. For those requiring fiberglass solutions, our wholesale fiberglass filter bag supplier offers factory-direct options. Fiberglass, with its excellent heat resistance, is perfect for high-temperature filtration processes. Just be aware of their higher costs and specific handling requirements.

Paint Filter Bag Flow Rate: Balancing Efficiency and Production Scale

When it comes to paint filtration, the term ‘flow rate’ isn’t just a technical specification—it’s the heartbeat of your production line. Think of it this way: if your paint filter bag can’t keep up with the volume of paint you’re processing, you’ll end up with bottlenecks, delays, and frustrated technicians. On the flip side, an oversized filter bag might seem like a safety net, but it could lead to unnecessary costs and reduced filtration precision. So, how do you strike the perfect balance?

First, let’s clarify what ‘flow rate’ means in this context. It refers to the volume of paint that can pass through the filter bag per unit of time, typically measured in gallons per minute (GPM) or liters per hour (L/H). This metric directly impacts your production efficiency. A higher flow rate means faster processing, but it also requires a filter bag with larger pores or a more robust design to handle the increased volume without clogging. For those seeking deeper technical insights into how flow rate affects filtration systems, consulting resources like the Filtration Society can provide valuable industry standards and research.

Now, here’s where things get interesting. The ideal flow rate for your paint filter bag depends heavily on your production scale. If you’re a small-scale operation producing custom coatings in batches, a lower flow rate might suffice. Why? Because you can afford to let the paint filter slowly, ensuring maximum purity and minimal waste. Plus, smaller filter bags are often more cost-effective for low-volume applications.

But what if you’re running a large-scale paint manufacturing plant, churning out thousands of gallons daily? In this case, a higher flow rate becomes essential. You need a filter bag that can keep pace with your production line to avoid costly downtime. However, don’t just rush for the highest GPM rating you can find. Consider the viscosity of your paints—thicker coatings require more pressure to push through, so a balance between flow rate and pressure tolerance is crucial.

Let’s dive deeper into the relationship between flow rate and production efficiency. Imagine two scenarios: In Scenario A, you use a filter bag with a flow rate that’s too low for your production volume. The result? Constant clogging, frequent filter changes, and a production line that’s always playing catch-up. In Scenario B, you opt for a filter bag with an optimally matched flow rate. The paint flows smoothly, filtration is efficient, and your technicians can focus on quality control rather than filter maintenance.

Which scenario sounds more appealing? Obviously, Scenario B is the winner. But how do you determine the right flow rate for your specific needs? Start by assessing your daily production volume. How many gallons of paint do you process in a typical shift? Next, consider the types of paints you’re working with—are they water-based, solvent-based, or high-viscosity epoxies? Each type has unique filtration requirements.

Don’t forget to factor in the desired level of filtration purity. If you’re producing high-end automotive coatings, you’ll need a filter bag that can remove even the tiniest particles, which might mean sacrificing some flow rate for finer filtration. Conversely, if you’re making industrial primers where absolute purity isn’t as critical, you can prioritize a higher flow rate.

Here’s a practical tip: When in doubt, consult with filter bag manufacturers or suppliers. They often have charts or calculators that can help you match your production needs with the ideal flow rate. And remember, it’s not a one-size-fits-all situation. You might need different filter bags for different product lines or even different times of the year if your production volume fluctuates seasonally.

In conclusion, the relationship between paint filter bag flow rate and production efficiency is a delicate dance. Choose a flow rate that’s too low, and you’ll drown in inefficiency. Go too high, and you might sacrifice filtration quality or waste money on oversized equipment. The key is to understand your production scale, paint types, and purity requirements, then select a filter bag that strikes the perfect balance. After all, in the world of paint filtration, flow rate isn’t just a number—it’s the rhythm that keeps your production line humming.

Selecting the ideal paint filter bag isn’t just about ticking boxes—it’s about aligning with your production’s unique demands. By now, you’ve seen how filtering accuracy, material durability, and flow rate interplay to define performance. Remember, the right paint filter bag can transform your production line, boosting efficiency and product quality. So, what’s your next move? Dive deeper, explore options, and pick the paint filter bag that propels your operations forward. The perfect match is out there—will you find it today?