Master Filter Bag Sizes: Boost Industrial Efficiency

In the intricate world of industrial filtration, the size of your filter bag can make or break your system’s efficiency. Have you ever wondered how the right filter bag sizes can transform your industrial setup, enhancing both performance and cost-effectiveness? Let’s dive into the science of selecting the perfect filter bag sizes tailored to your industrial needs, unlocking a new era of filtration excellence.

Industrial Equipment Demands: Filter Bag Sizes Tailored to Your Needs

When it comes to industrial filtration, one size does not fit all. The diverse range of industrial equipment, from chemical processing plants to food manufacturing lines, imposes unique demands on filter bag sizes. Understanding these demands is crucial for optimizing filtration efficiency and maintaining operational continuity. Let’s dive into the specific requirements that different industrial setups have for filter bag sizes, focusing on three key factors: filtration area, flow rate needs, and spatial constraints.

Firstly, filtration area is a fundamental consideration. The size of the filter bag directly correlates with the surface area available for trapping particles. For instance, in a cement plant where dust generation is high, larger filter bags with greater surface areas are essential to handle the volume of particulates without frequent clogging or replacement. Conversely, in a pharmaceutical cleanroom, where precision is paramount and the volume of contaminants is relatively low, smaller, more numerous filter bags might be preferred to ensure even distribution of airflow and consistent filtration quality.

Next up, flow rate demands play a pivotal role. Different industrial processes generate varying amounts of gaseous or liquid effluents that need filtering. A petrochemical refinery, for example, processes vast quantities of crude oil, producing high-flow-rate gases that require robust, large-capacity filter bags to prevent pressure drops and maintain system efficiency. On the other hand, a beverage bottling plant dealing with lower volumes of particulates in its air filtration system might opt for moderately sized filter bags, such as polyester pocket filter bags, that balance cost-effectiveness with adequate flow handling capabilities.

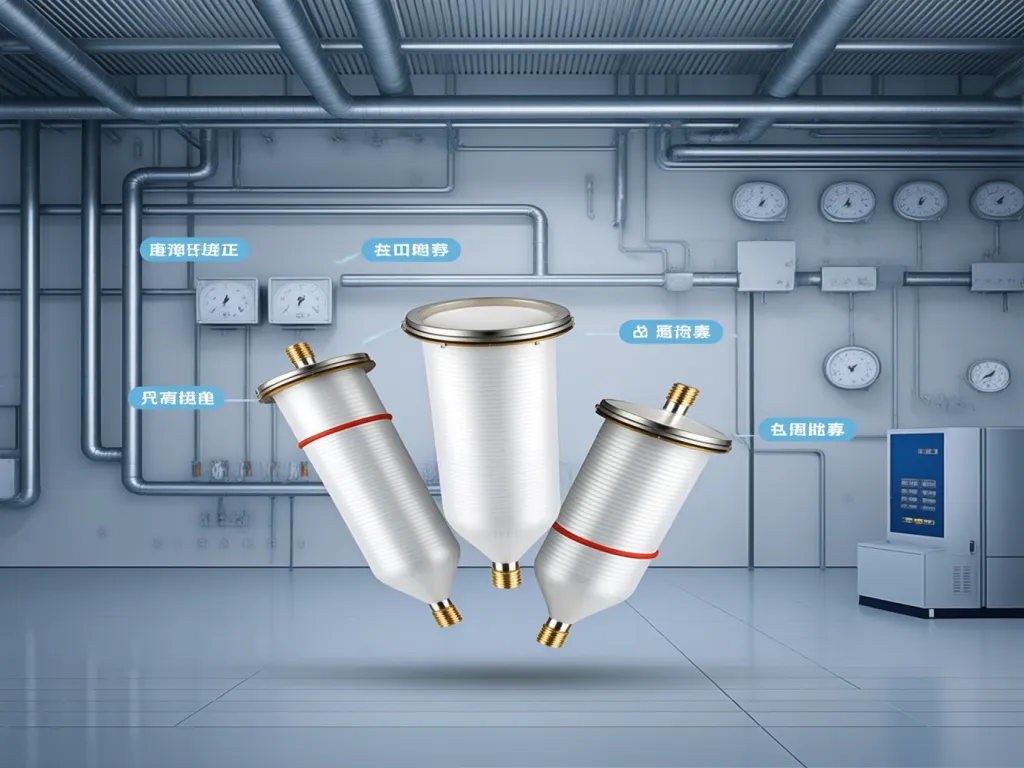

Spatial constraints cannot be overlooked either. In compact industrial environments, such as urban wastewater treatment facilities, every inch counts. Here, the challenge lies in selecting filter bag sizes that maximize filtration capacity within limited space. This often means opting for custom-sized or specially designed filter bags that fit snugly into existing filtration units without compromising performance. Innovations like pleated filter bags, which increase surface area without significantly enlarging the physical footprint, are becoming increasingly popular in such settings.

But how do you know if you’re making the right choice? Start by conducting a thorough assessment of your industrial setup. Measure the available space, calculate the expected flow rates based on process outputs, and estimate the required filtration area based on particulate load. Don’t forget to factor in future scalability; choosing filter bags that can accommodate potential increases in production volume can save you from costly upgrades down the line.

Remember, the goal is to strike a balance between efficiency, cost, and maintainability. Larger filter bags may offer higher filtration capacities but come with higher initial costs and potentially more complex maintenance procedures. Smaller bags, while cheaper and easier to handle, might not suffice for high-demand applications, leading to frequent replacements and downtime.

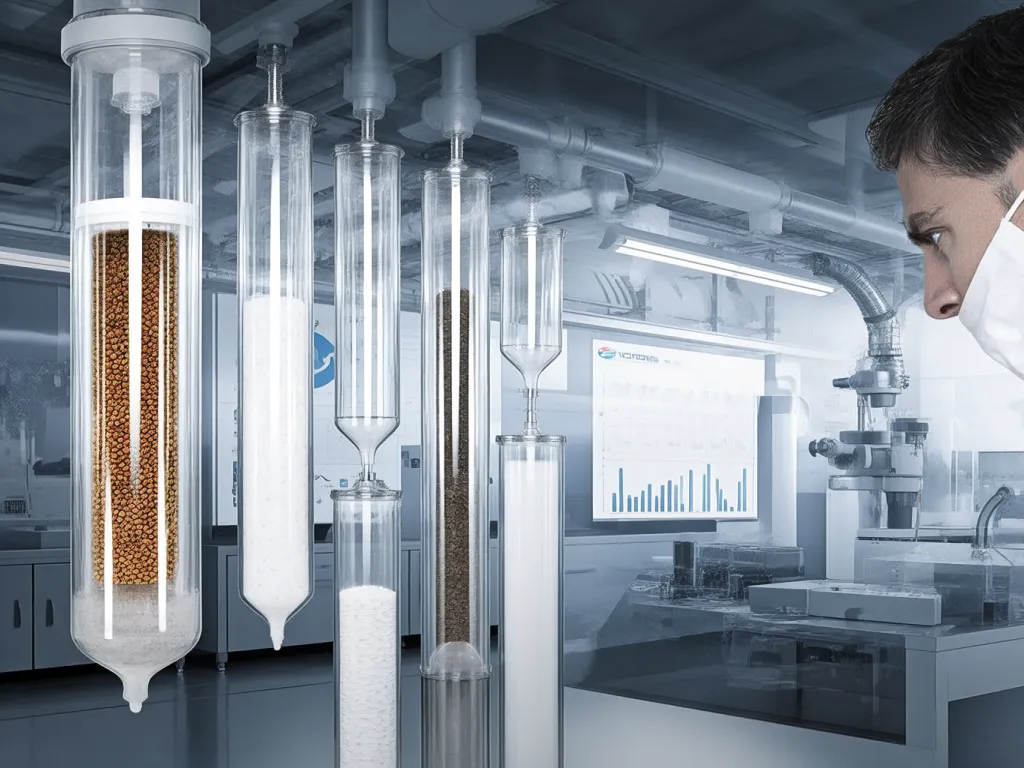

Chemical Processing: Balancing Capacity and Precision

In chemical processing plants, the stakes are high. Corrosive chemicals, high temperatures, and abrasive particles demand filter bags that can withstand harsh conditions while maintaining precise filtration. Here, the focus shifts towards selecting filter bags made from durable materials like PTFE or fiberglass, which can handle chemical exposure without degrading. For instance, PTFE-coated polyester dust filter bags are a popular choice for their chemical resistance. The size selection hinges on balancing the need for large filtration areas to manage high particulate loads with the precision required to capture fine chemical residues, ensuring product purity and safety.

Food Manufacturing: Hygiene and Efficiency

Food manufacturing facilities prioritize hygiene above all else. Filter bags in these settings must not only capture contaminants effectively but also be easy to clean and replace to prevent cross-contamination. Smaller, more numerous filter bags are often favored for their ease of handling and quick changeover times. However, the choice of size must still consider the volume of air or liquid needing filtration, ensuring that the system can handle peak production periods without compromising on food safety standards. For example, polyester dust collector filter bags are commonly used in food manufacturing due to their effectiveness and ease of maintenance.

Power Generation: Handling High Volumes with Ease

Power generation plants, whether coal-fired, gas-powered, or renewable energy-based, generate significant amounts of particulates that need efficient filtration. Large filter bags with high surface areas are typically employed to manage the high volumes of flue gas or ash. The selection process involves calculating the expected particulate load, considering factors like fuel type and combustion efficiency, to determine the optimal filter bag size that ensures continuous operation and minimal emissions. For specific applications, such as coal-fired plants, FMS felt filter bags may be used for their durability and high filtration efficiency.

The Interplay Between Filter Bag Sizes and Filtration Precision: Optimizing Performance

When it comes to industrial filtration, the size of your filter bag isn’t just a matter of fitting into your equipment—it’s a critical factor influencing filtration precision and overall system efficiency. You might be thinking, ‘How can something as simple as size have such a profound impact?’ Well, let’s dive into the nitty-gritty of how filter bag sizes intertwine with filtration accuracy and what you can do to harness this relationship for optimal performance. First off, filtration precision is all about how effectively your filter bag can capture and retain particles of a certain size. This is where the concept of ‘micron rating’ comes into play. Essentially, a filter bag’s micron rating tells you the smallest particle size it can reliably trap. But here’s the kicker: the size of your filter bag can influence this rating in subtle yet significant ways. Imagine you have a compact filter bag with a small surface area. To achieve a high filtration rate, you might need to increase the flow velocity through the bag. However, higher flow rates can lead to increased pressure drops and potentially bypass of smaller particles, reducing filtration precision. On the flip side, a larger filter bag with more surface area can handle higher flow rates without compromising precision, as the increased surface area allows for more even distribution of flow and better particle capture. Now, let’s talk about reducing impurity penetration. This is where the magic of adjusting filter bag sizes really shines. By selecting a filter bag size that matches your specific industrial application’s demands, you can minimize the risk of impurities slipping through the cracks. For instance, in applications where fine particulates are a concern, a larger filter bag with a finer micron rating can provide the necessary barrier to keep your process stream clean. But it’s not just about going big. Sometimes, a smaller, more specialized filter bag can be the answer. For example, in confined spaces or where precise control over filtration is required, a compact, high-efficiency filter bag might be the way to go. The key is understanding your application’s unique needs and selecting a filter bag size that aligns with those requirements. So, how do you determine the right size? It starts with a thorough assessment of your industrial process. Consider factors like the type and size of particles you need to filter, the desired flow rate, and the available space within your equipment. From there, you can work with filter bag manufacturers or consultants to identify the optimal size and micron rating for your needs. Remember, it’s not a one-size-fits-all scenario. Each industrial application is unique, and so too should be your approach to selecting filter bag sizes. By taking the time to understand the interplay between filter bag sizes and filtration precision, you can unlock significant improvements in your process’s efficiency and product quality.

The Science Behind Size and Precision

Let’s get a bit more technical. The relationship between filter bag size and filtration precision is rooted in fluid dynamics and particle capture mechanisms. A larger filter bag offers more surface area for particles to adhere to, which can enhance filtration efficiency, especially for finer particles. Conversely, a smaller bag might require higher flow rates to achieve the same throughput, potentially compromising precision. This isn’t just about cleaner products—it’s about reducing wear and tear on downstream equipment, minimizing maintenance costs, and extending the lifespan of your entire filtration system.

Real-World Applications and Case Studies

To bring this concept to life, let’s look at a few real-world examples. In the pharmaceutical industry, where purity is paramount, selecting the right filter bag size can mean the difference between a high-quality product and a costly recall. By using larger filter bags with finer micron ratings, manufacturers have been able to achieve near-zero impurity levels in their final products. In the food and beverage sector, where taste and safety are critical, filter bag size optimization has led to cleaner extracts and juices, free from unwanted solids and contaminants. This not only improves product quality but also enhances consumer satisfaction and brand reputation. And in the chemical processing industry, where harsh conditions and aggressive chemicals are the norm, choosing the right filter bag size can prevent premature failure and ensure consistent performance, even in the most demanding environments.

Real-World Success Stories: Filter Bag Sizes in Action

Let’s dive into some real-world examples where selecting the right filter bag sizes made all the difference. These stories aren’t just about numbers; they’re about how a simple change in size can revolutionize your industrial filtering process, boosting efficiency and saving you money.

Case Study 1: Chemical Processing Plant’s Efficiency Leap

Imagine a bustling chemical processing plant where every minute counts. This plant was facing a recurring issue: their existing filter bags were too small, causing frequent clogs and downtime. The plant engineers, after a thorough analysis, decided to switch to larger filter bags with a diameter of 16 inches and a length of 40 inches, tailored specifically for their high-flow applications.

The result? A staggering 30% increase in filtration capacity. But that’s not all. The larger surface area meant fewer clogs, reducing maintenance downtime by 25%. And here’s the kicker: the cost per unit of filtered material dropped by 15%, thanks to the extended lifespan of the larger bags and reduced labor costs for maintenance.

Case Study 2: Food Processing Facility’s Cost Savings

Now, let’s shift gears to a food processing facility. They were using standard-sized filter bags, but their unique product mix required a more customized approach. After consulting with a filtration expert, they opted for a set of filter bags with a non-standard diameter of 14 inches and a custom length of 36 inches, designed to fit their specific dust collectors.

The impact was immediate. The new filter bags improved airflow efficiency by 20%, leading to a cleaner production environment and better product quality. But the real win was in the cost savings. Over a year, the facility saved over $20,000 in operational costs, primarily due to reduced energy consumption (less pressure drop across the filters) and fewer filter replacements.

Case Study 3: Pharmaceutical Manufacturer’s Precision Boost

In the pharmaceutical industry, precision is everything. A manufacturer was struggling with inconsistent particle removal in their dry powder inhaler production line. The issue? Their filter bags were too large, allowing fine particles to bypass the filtration process.

The solution? A switch to smaller, more precisely sized filter bags with a diameter of 10 inches and a length of 24 inches, optimized for their specific particle size distribution. The result was a dramatic improvement in product purity, with a 99.9% reduction in unwanted particles. And guess what? The cost per batch dropped by 10%, thanks to fewer rejections and rework due to contamination issues.

Why Size Matters: The Underlying Science

These case studies highlight a crucial point: the right filter bag size isn’t just about fitting the equipment; it’s about optimizing the entire filtration process. Larger bags offer more surface area, reducing pressure drop and increasing flow rates. Smaller bags, when precisely sized, can capture finer particles more effectively, improving product quality.

But how do you know which size is right for you? It starts with understanding your specific needs: the type of material you’re filtering, the flow rate of your system, and the space constraints of your equipment. From there, it’s about finding the sweet spot—the size that maximizes efficiency without compromising on cost or performance.

Your Turn: Making the Right Choice

Now, it’s your turn to apply these lessons. Start by assessing your current filtration setup. Are you experiencing frequent clogs or pressure drops? Are your filter bags lasting as long as they should? If not, it might be time to reconsider your size.

Remember, the right filter bag size isn’t a one-size-fits-all solution. It’s about finding the perfect match for your unique industrial needs. And the best part? The savings—both in terms of efficiency and cost—can be substantial. So, why wait? Dive into the world of filter bag sizes and unlock the full potential of your industrial filtering process today!

Case Study 1: Chemical Processing Plant’s Efficiency Leap

Imagine a bustling chemical processing plant where every minute counts. This plant was facing a recurring issue: their existing filter bags were too small, causing frequent clogs and downtime. The plant engineers, after a thorough analysis, decided to switch to larger filter bags with a diameter of 16 inches and a length of 40 inches, tailored specifically for their high-flow applications. The result? A staggering 30% increase in filtration capacity. But that’s not all. The larger surface area meant fewer clogs, reducing maintenance downtime by 25%. And here’s the kicker: the cost per unit of filtered material dropped by 15%, thanks to the extended lifespan of the larger bags and reduced labor costs for maintenance.

Case Study 2: Food Processing Facility’s Cost Savings

Now, let’s shift gears to a food processing facility. They were using standard-sized filter bags, but their unique product mix required a more customized approach. After consulting with a filtration expert, they opted for a set of filter bags with a non-standard diameter of 14 inches and a custom length of 36 inches, designed to fit their specific dust collectors. The impact was immediate. The new filter bags improved airflow efficiency by 20%, leading to a cleaner production environment and better product quality. But the real win was in the cost savings. Over a year, the facility saved over $20,000 in operational costs, primarily due to reduced energy consumption (less pressure drop across the filters) and fewer filter replacements.

Case Study 3: Pharmaceutical Manufacturer’s Precision Boost

In the pharmaceutical industry, precision is everything. A manufacturer was struggling with inconsistent particle removal in their dry powder inhaler production line. The issue? Their filter bags were too large, allowing fine particles to bypass the filtration process.

The solution? A switch to smaller, more precisely sized filter bags with a diameter of 10 inches and a length of 24 inches, optimized for their specific particle size distribution. The result was a dramatic improvement in product purity, with a 99.9% reduction in unwanted particles. And guess what? The cost per batch dropped by 10%, thanks to fewer rejections and rework due to contamination issues.

To wrap up, selecting the right filter bag sizes is a game-changer in industrial filtration. It’s not just about fitting a bag into your system; it’s about optimizing performance, reducing costs, and achieving unparalleled efficiency. By understanding your equipment’s unique requirements and the impact of filter bag sizes on filtration performance, you’re well on your way to revolutionizing your industrial processes. Ready to take your filtration to the next level? Start by evaluating your filter bag sizes today and witness the transformative power of precision in industrial filtration. What’s your next move in enhancing your system’s efficiency?