Industrial Filtration Mastery: Felt Filter Bag Guide

In the world of industrial filtration, the difference between smooth operations and costly downtime often hinges on one component: the felt filter bag. Whether you’re managing chemical reactors, food processing lines, or pharmaceutical systems, choosing the right felt filter bag for industrial use isn’t just about plugging a gap—it’s about aligning performance with precision. But with countless materials, sizes, and filtration ratings, how do you ensure your selection actually meets your equipment’s demands? Let’s dive into the art of matching felt filter bags to your industrial needs.

Analyzing Industrial Equipment Types and Filtration Needs: From Chemicals to Food and Pharmaceuticals

When it comes to industrial filtration, one size definitely doesn’t fit all. Each industry—whether it’s chemicals, food processing, or pharmaceuticals—has its own set of challenges and demands. So, how do you make sure your felt filter bag for industrial use is up to the task? Let’s break it down by industry and see what makes each one tick.

Chemical Industry: Tough Conditions, Tough Filters

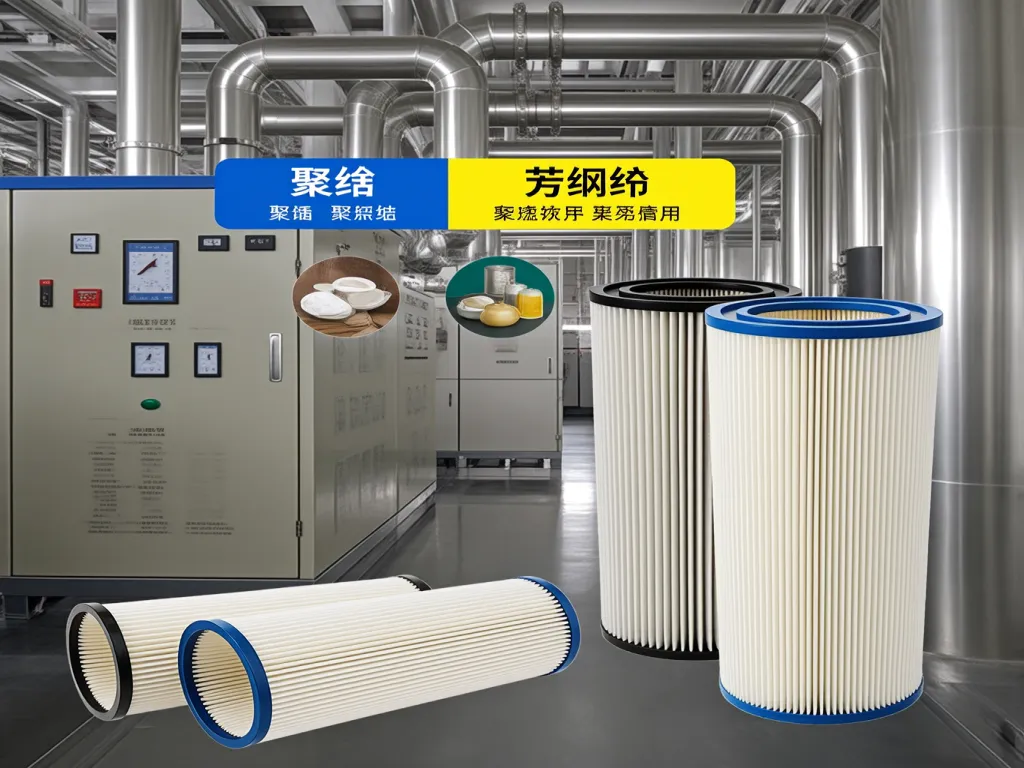

In the chemical industry, the stakes are high. You’re dealing with corrosive substances, high temperatures, and sometimes even toxic fumes. That means your filtration system needs to be robust. The felt filter bag you choose here must have excellent chemical resistance. Polyester and polypropylene felts are popular choices because they can withstand a wide range of chemicals without degrading. But what about temperature? Some chemical processes operate at extremely high temperatures, so you’ll need a felt filter bag that can handle the heat. Look for materials like aramid, which can tolerate temperatures up to 400°F (204°C) or more.

But it’s not just about the material. The filtration precision is crucial too. Chemicals often need to be filtered to a very fine degree to remove impurities that could affect the final product’s quality or safety. A high-efficiency felt filter bag with a tight weave can capture even the smallest particles, ensuring your chemical process runs smoothly and safely. For specific solutions, consider checking out our high-efficiency polyester felt filter bag designed for industrial use.

Food Processing: Cleanliness and Purity Are Non-Negotiable

Now, let’s switch gears to the food processing industry. Here, the focus shifts to cleanliness and purity. Contamination is a big no-no, so your felt filter bag must be made from food-grade materials that won’t leach any harmful substances into the food. Polyester is a common choice because it’s FDA-approved for food contact and is easy to clean. But what about the filtration needs? In food processing, you’re often dealing with liquids or semi-liquids that need to be filtered to remove solids like spices, herbs, or even small pieces of fruit.

The felt filter bag you choose should have a balance between filtration precision and flow rate. Too tight a weave, and the flow rate might slow down, causing backups in your production line. Too loose, and you might not capture all the solids you need to. It’s a delicate balance, but with the right felt filter bag, you can achieve optimal filtration without sacrificing efficiency. And let’s not forget about temperature. Some food processing steps, like pasteurization, involve high temperatures, so your felt filter bag must be able to handle that without losing its shape or effectiveness.

Pharmaceuticals: Precision and Sterility Are Key

Finally, let’s talk about the pharmaceutical industry. Here, precision and sterility are paramount. You’re dealing with drugs and medications that need to be pure and free from contaminants. That means your filtration system must be top-notch. The felt filter bag you choose should have a very high filtration precision, capable of capturing even the tiniest particles that could affect the drug’s efficacy or safety.

But it’s not just about the particles. Sterility is a huge concern in pharmaceuticals. Your felt filter bag must be made from materials that can be sterilized, whether through autoclaving, gamma irradiation, or other methods. Polyester and polypropylene are again good choices because they can withstand sterilization processes without degrading. And what about chemical resistance? Some pharmaceutical processes involve solvents or other chemicals, so your felt filter bag must be able to handle those without breaking down.

Matching Filtration Needs to Equipment and Material Characteristics

So, how do you match your filtration needs to the right felt filter bag? It all starts with understanding your equipment and the material you’re processing. What’s the temperature range? What chemicals are involved? How fine does the filtration need to be? Once you have those answers, you can start narrowing down your options.

For example, if you’re in the chemical industry and dealing with high temperatures and corrosive substances, you’ll want a felt filter bag made from aramid or another high-temperature, chemical-resistant material. If you’re in food processing and need a balance between filtration precision and flow rate, a polyester felt with a moderate weave might be your best bet. Explore our range of polyester felt filter bags for efficient liquid filtration. And in pharmaceuticals, where precision and sterility are key, look for a felt filter bag with a very high filtration precision and materials that can be sterilized.

Remember, choosing the right felt filter bag for industrial use isn’t just about the material. It’s about understanding your specific needs and finding a solution that meets them. So, take the time to assess your equipment, your material, and your filtration requirements. With the right felt filter bag, you can ensure your industrial processes run smoothly, safely, and efficiently.

Chemical Industry Filtration: Resisting Corrosion and Heat

The chemical industry demands filtration solutions that can withstand corrosive substances and high temperatures. Polyester and polypropylene felts are favored for their chemical resistance, while aramid is chosen for its ability to tolerate extreme heat. Filtration precision is also critical, as even small impurities can affect product quality and safety. A high-efficiency felt filter bag with a tight weave ensures optimal filtration in chemical processes.

Food Processing Filtration: Balancing Precision and Flow

In food processing, cleanliness and purity are paramount. Food-grade materials like polyester are used for felt filter bags to prevent contamination. The filtration needs here involve balancing precision with flow rate to avoid production line backups. Temperature resistance is also important, as some food processing steps, like pasteurization, involve high temperatures that the felt filter bag must withstand without losing effectiveness.

Pharmaceutical Filtration: Prioritizing Precision and Sterility

The pharmaceutical industry requires filtration systems that are both precise and sterile. Felt filter bags must have high filtration precision to capture tiny particles that could affect drug efficacy or safety. Sterility is a major concern, so materials that can be sterilized, such as polyester and polypropylene, are preferred. Chemical resistance is also important, as some pharmaceutical processes involve solvents or other chemicals.

The Art of Material Selection: Detailed Analysis of Felt Filter Bag Material Properties

When it comes to industrial filtration, the material of your felt filter bag can make or break your operation. Choosing the right material isn’t just about cost; it’s about ensuring durability, efficiency, and safety in your specific industrial environment. Let’s dive into the most common materials used in felt filter bags for industrial use—polyester, polypropylene, and aramid—and explore how their unique properties can match different industrial scenarios.

Polyester Felt Filter Bags: The All-Rounder

Polyester is the go-to material for many industrial applications, and for good reason. It offers a great balance of affordability, durability, and chemical resistance. Polyester felt filter bags, such as those found here, can handle temperatures up to around 130°C (266°F), making them suitable for a wide range of industrial processes. They’re also resistant to most acids and alkalis, though they may not be the best choice for highly corrosive environments.

But here’s where polyester really shines: its abrasion resistance. If your process involves filtering abrasive particles, polyester felt filter bags can withstand the wear and tear better than many other materials. This makes them ideal for industries like cement production, metalworking, and even food processing where gritty or fibrous materials are common.

Polypropylene Felt Filter Bags: The Chemical Warrior

If you’re dealing with highly corrosive chemicals, polypropylene is your material of choice. Polypropylene felt filter bags offer excellent resistance to a wide range of acids, alkalis, and solvents. They can handle temperatures up to about 90°C (194°F), which is lower than polyester but still sufficient for many chemical processing applications.

What sets polypropylene apart is its ability to remain stable in harsh chemical environments where other materials might degrade or fail. This makes it perfect for industries like electroplating, chemical manufacturing, and wastewater treatment where aggressive chemicals are part of the daily routine.

Aramid Felt Filter Bags: The High-Temperature Hero

When your industrial process involves extreme heat, aramid (often known by its trade name, Kevlar) is the material you need. Aramid felt filter bags, like the aramid fiber felt high-temperature resistant filtration media, can withstand temperatures up to 200°C (392°F) or even higher, depending on the specific formulation. This makes them indispensable in industries like asphalt production, incineration, and power generation where high temperatures are the norm.

But aramid isn’t just about heat resistance. It also offers excellent dimensional stability, meaning it won’t shrink or stretch under extreme conditions. This is crucial for maintaining consistent filtration performance over time. Additionally, aramid has good abrasion resistance, though not quite as high as polyester.

Matching Materials to Industrial Scenarios

So, how do you choose the right material for your specific industrial scenario? Start by assessing your operating environment. What are the maximum temperatures your filter bag will face? What kinds of chemicals or abrasive materials will it encounter?

For general-purpose industrial filtration with moderate temperatures and chemical exposure, polyester is often the best choice. It offers a good balance of performance and cost-effectiveness.

If you’re dealing with highly corrosive chemicals, even at moderate temperatures, polypropylene is the way to go. Its chemical resistance will ensure longevity and reliability in these harsh conditions.

And for high-temperature applications where other materials would fail, aramid is your hero. Its ability to withstand extreme heat without compromising performance makes it invaluable in these demanding environments.

Remember, the right material choice can significantly extend the life of your felt filter bag, reduce downtime, and improve overall filtration efficiency. Don’t be afraid to consult with experts or conduct trials to find the perfect match for your industrial needs.

Polyester Felt Filter Bags in Food Processing

In the food processing industry, polyester felt filter bags are a popular choice due to their ability to handle a variety of particulates, from flour and sugar to spices and herbs. Their resistance to abrasion ensures they can withstand the constant flow of materials without breaking down quickly. Plus, polyester is FDA-approved for food contact, making it a safe choice for filtering edible products. For high-efficiency solutions, consider felt filter high-efficiency solutions tailored for industrial filtration.

Polypropylene Felt Filter Bags in Electroplating

Electroplating facilities rely heavily on polypropylene felt filter bags to handle the corrosive chemicals used in the plating process. These bags can withstand acids like sulfuric and hydrochloric acid, as well as alkalis, without degrading. This ensures consistent filtration performance and protects downstream equipment from contamination. For a comprehensive filtration solution, explore felt filter high-efficiency industrial filtration solutions.

Aramid Felt Filter Bags in Asphalt Production

Asphalt production involves extremely high temperatures, often exceeding 150°C (302°F). Aramid felt filter bags are the only choice that can reliably handle these conditions without melting or losing structural integrity. Their heat resistance ensures efficient filtration of asphalt fumes and particulates, even in the most demanding production environments. For specialized asphalt filtration needs, check out felt filter high-efficiency solutions for industrial filtration.

Filtration Precision and Production Process Optimization: Exploring the Impact of Filtration Precision on Product Quality, Production Efficiency, and Achieving the Optimal Balance of Filtration Efficiency and Cost Through the Right Felt Filter Bag

When it comes to industrial filtration, the precision of the felt filter bag you choose can make or break your production process. But why is filtration precision so crucial, and how does it tie into production efficiency and product quality? Let’s dive in.

First off, filtration precision directly affects the purity of your end product. In industries like pharmaceuticals or food processing, even the tiniest impurities can lead to quality issues, regulatory non-compliance, or worse—product recalls. Imagine a pharmaceutical company producing life-saving drugs. If the filtration system isn’t precise enough, contaminants could slip through, compromising the drug’s efficacy or safety. That’s a risk no one can afford.

But it’s not just about product quality. Filtration precision also plays a pivotal role in production efficiency. A filter bag with the right precision level ensures that only the desired particles are retained, while the rest flows smoothly through the system. This means less downtime for cleaning or replacing clogged filters, fewer interruptions in the production line, and ultimately, higher throughput. Think about a chemical plant where continuous operation is key. A poorly chosen filter bag could lead to frequent blockages, forcing the plant to shut down for maintenance, costing time and money.

Now, let’s talk about cost. While high-precision filter bags might seem like the obvious choice, they often come with a higher price tag. But is it always worth it? Not necessarily. The key is to strike the right balance between filtration efficiency and cost. For instance, in a low-risk application where the stakes aren’t as high, a moderately precise filter bag might suffice, saving you money without compromising on performance. On the other hand, in high-stakes industries like aerospace or semiconductor manufacturing, where even microscopic contaminants can cause catastrophic failures, investing in top-tier precision is a no-brainer. For more insights into how different industries approach filtration needs, you may refer to this industry-specific filtration guide.

So, how do you find that sweet spot? It starts with understanding your specific filtration needs. What’s the size and type of particles you’re dealing with? What’s the flow rate of your system? How often do you need to clean or replace the filters? Answering these questions will help you narrow down your options and choose a felt filter bag that offers the right level of precision at a cost you can justify.

But don’t stop there. Consider the long-term savings too. A slightly more expensive filter bag that lasts longer and requires less maintenance could end up being more cost-effective in the long run. Plus, the peace of mind that comes with knowing your filtration system is operating at peak efficiency is priceless.

In essence, choosing the right felt filter bag for industrial use is a delicate dance between filtration precision, production efficiency, and cost. By taking the time to understand your specific needs and weighing the pros and cons of each option, you can find the perfect balance that keeps your production line running smoothly, your products top-notch, and your bottom line healthy.

The Role of Filtration Precision in Product Quality

Filtration precision is the gatekeeper of product quality. In industries where purity is paramount, like pharmaceuticals or food and beverage, even minor impurities can have dire consequences. A felt filter bag with the right precision level ensures that only the cleanest, purest product reaches the end consumer. For example, in dairy processing, a high-precision filter bag can remove bacteria and other contaminants, ensuring the milk is safe for consumption. On the flip side, a low-precision filter might let harmful particles through, risking public health and damaging the brand’s reputation.

Filtration Precision and Production Efficiency

Production efficiency is all about keeping the production line moving smoothly. A felt filter bag that’s too coarse might let too many particles through, clogging downstream equipment and causing interruptions. Conversely, a bag that’s too fine could clog up quickly, requiring frequent replacements and downtime. The sweet spot is a filter bag that offers just the right level of precision—enough to catch harmful particles but not so much that it hampers the flow. This balance ensures continuous operation, reduces maintenance costs, and boosts overall efficiency.

Cost Considerations in Felt Filter Bag Selection

Cost is always a factor, but it shouldn’t be the only one. While high-precision filter bags might seem expensive upfront, they can save you money in the long run by reducing downtime, maintenance costs, and product recalls. On the other hand, a cheaper, less precise bag might seem like a bargain, but it could end up costing you more in the long run if it leads to frequent breakdowns or quality issues. The key is to evaluate your specific needs and choose a bag that offers the best value for your money, considering both short-term and long-term costs.

Choosing the right felt filter bag for industrial use isn’t a gamble—it’s a calculated decision that impacts efficiency, safety, and costs. By understanding your equipment’s demands, the chemical environment, and the trade-offs between filtration precision and longevity, you can transform filtration from a maintenance headache into a strategic advantage. Ready to upgrade your industrial filtration? Explore our material guides and equipment-specific recommendations, then share your success stories or lingering questions in the comments. After all, every industrial challenge is an opportunity to filter smarter.