Filter Bag Size Chart: Your Industrial Match Guide

Ever found yourself puzzled over which filter bag size fits your industrial filtration system like a glove? Navigating the sea of options for filter bag sizes can be daunting, especially when efficiency and cost-effectiveness are on the line. Enter the filter bag size chart—your ultimate roadmap to precision in industrial filtration. In this guide, we’ll demystify the process, ensuring you select the perfect fit every time. Ready to transform your filtration game?

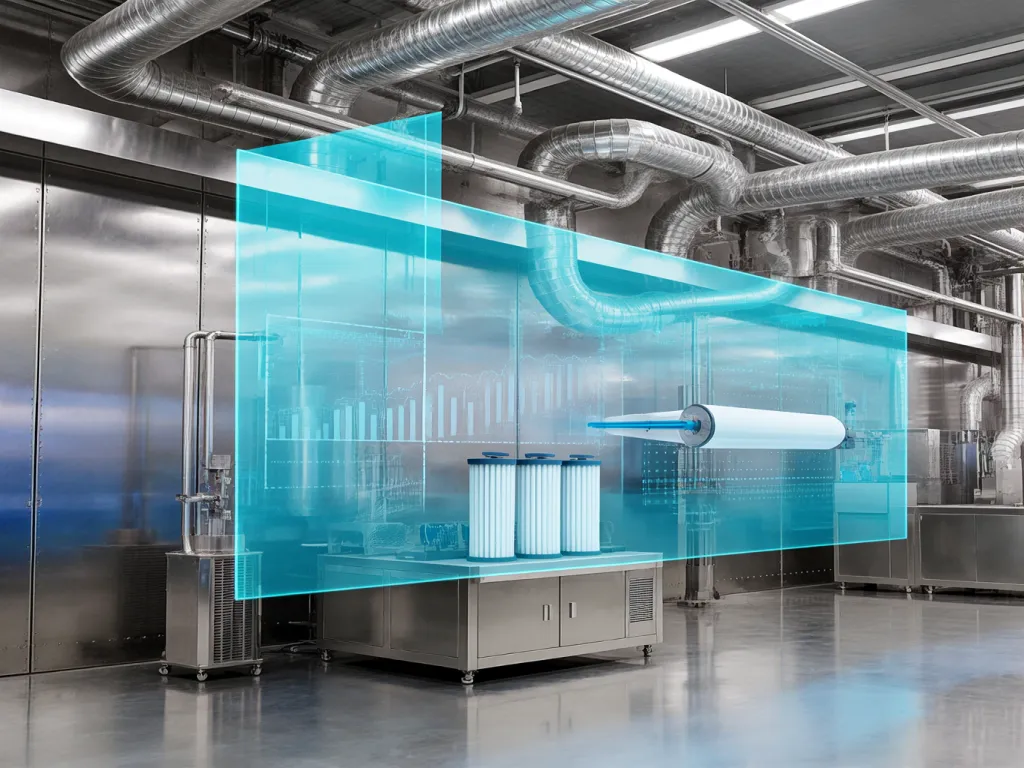

Understanding the Correspondence Between Filter Equipment Models and Filter Bag Size Charts

When it comes to industrial filtration systems, the devil truly is in the details—especially when we’re talking about filter bag size charts. You see, not all filter equipment is created equal. Each model, whether it’s a baghouse, a cartridge collector, or a dust collector, comes with its own set of specifications and requirements. And guess what? The filter bag size chart isn’t just a random list of dimensions; it’s a carefully crafted guide that ensures your filtration system operates at peak efficiency. Let’s break it down.

First off, why does the filter bag size matter so much? Well, imagine trying to fit a square peg into a round hole—it just doesn’t work, right? The same principle applies here. If your filter bag is too small, it won’t capture all the particulates, leading to reduced filtration efficiency and potentially, equipment damage. On the flip side, if it’s too large, it might not fit properly, causing leaks and again, compromising the filtration process. So, how do you find the perfect match? It all starts with understanding your filter equipment model. Each model has a unique design, flow rate, and pressure drop characteristics. These factors directly influence the size and type of filter bag you need. For instance, a high-pressure system might require a stronger, more durable filter bag material, such as those used in our nonwoven needle felt filter bags, while a low-flow system could get by with a lighter, more flexible option.

Now, let’s talk about the filter bag size chart itself. This isn’t just a list of numbers; it’s a roadmap to optimal filtration. The chart typically includes dimensions like diameter, length, and sometimes even the neck size or fitting type. By cross-referencing your equipment’s specifications with the size chart, you can pinpoint the exact filter bag size that will fit like a glove. But wait, there’s more! Don’t forget to consider the operating conditions. Are you dealing with high temperatures? Corrosive chemicals? Abrasive particles? All these factors can influence your filter bag choice. For example, if you’re working in a high-temperature environment, you’ll need a filter bag made from heat-resistant materials like fiberglass or PTFE. And if you’re dealing with corrosive substances, a stainless steel or polypropylene filter bag might be your best bet. In some specific applications, like those requiring a 7-inch diameter filter bag, you can explore our 7-inch polyester filter sock for a reliable solution.

Here’s a pro tip: don’t be afraid to consult the manufacturer’s recommendations. They’ve spent countless hours testing and refining their equipment, so they know exactly which filter bag sizes work best with each model. Plus, many manufacturers offer custom sizing options, so if your application is particularly unique, you can get a filter bag tailored to your exact needs. In conclusion, understanding the correspondence between filter equipment models and filter bag size charts is crucial for maximizing filtration efficiency. By taking the time to research and match the right filter bag size to your equipment, you’ll not only improve performance but also extend the lifespan of your filtration system. So, next time you’re shopping for filter bags, remember: size does matter!

Analyzing the Working Principles of Filtration Equipment and Filter Bag Size Selection

When it comes to industrial filtration systems, understanding the inner workings of your equipment isn’t just academic—it’s the cornerstone of efficient operation and optimal filter bag selection. Imagine trying to fit a square peg into a round hole; that’s what happens when you choose the wrong filter bag size for your filtration device. So, let’s dive into the mechanics of how these systems operate and why these details are pivotal in selecting the perfect filter bag size chart.

First off, every filtration system operates under specific parameters, with pressure and flow rate being the MVPs. Pressure, in this context, refers to the force exerted by the fluid as it passes through the filter media. Too much pressure, and you risk damaging the filter bag or even the filtration housing itself. Too little, and the filtration process becomes sluggish, inefficient, and downright ineffective. It’s a delicate balance, akin to finding the sweet spot on a guitar string—too tight, and it snaps; too loose, and it sounds terrible.

Now, let’s talk flow rate. This is the volume of fluid that passes through the filter over a given time. A high flow rate demands a larger surface area for filtration to prevent clogging and maintain efficiency. Conversely, a low flow rate might allow for a smaller filter bag, but only if the pressure is managed correctly. Think of it like a highway during rush hour: too many cars (fluid) on a narrow road (small filter bag) with no traffic control (pressure management) equals a gridlock (clogged filter).

So, how does this translate to choosing the right filter bag size? Well, it’s all about matching the filter bag’s dimensions to the equipment’s operational parameters. A filter bag that’s too small for a high-pressure, high-flow system will wear out quickly, leading to frequent replacements and increased downtime. On the flip side, an oversized filter bag in a low-pressure, low-flow setup is like using a sledgehammer to crack a nut—overkill and wasteful. To get it right, you need to consider the maximum operating pressure and flow rate of your equipment. These figures are usually provided by the manufacturer and serve as your guideposts. It’s not just about plugging in numbers; it’s about understanding the synergy between your equipment’s capabilities and the filter bag’s design.

Moreover, don’t overlook the importance of filter media material. Different materials have varying pressure drop characteristics and flow rates. For instance, a polyester filter bag might handle higher pressures and flow rates better than a paper one, but it also comes with a higher price tag. Balancing cost, performance, and longevity is key here. In essence, selecting the right filter bag size isn’t a one-size-fits-all scenario. It requires a nuanced understanding of your filtration equipment’s working principles, particularly pressure and flow rate. By taking the time to analyze these factors and consulting a reliable filter bag size chart, you can ensure that your filtration system operates at peak efficiency, saving you time, money, and headaches down the line. So, next time you’re faced with choosing a filter bag, remember: it’s not just about the size; it’s about the fit.

Case Study: Successful Filter Bag Size Chart Selection for Overhauled Filtration Systems

Let’s dive into a real-world scenario where the right filter bag size chart made all the difference. Imagine a mid-sized chemical processing plant struggling with frequent filter bag replacements and inconsistent filtration quality. Their existing setup featured an outdated filtration system, leading to inefficiencies and higher operational costs. The first step in our journey was to understand their specific equipment model and operational parameters. The plant used a horizontal vacuum belt filter (HVBF), which is common in chemical processing for its ability to handle high-volume slurries. However, the original filter bags were undersized, causing excessive pressure drops and frequent clogging. This not only affected the filtration rate but also increased energy consumption as the system worked harder to maintain flow. By referring to a detailed filter bag size chart tailored for HVBF models, we identified the optimal dimensions. The chart considered factors like belt speed, slurry viscosity, and desired filtration rate. We recommended a switch to larger filter bags with a specific micron rating, such as those available in our wholesale polyester dust collector filter bags or factory wholesale polyester dust collector filter bags, designed to handle the plant’s unique chemical composition without compromising on filtration efficiency. The results? Dramatic. Within weeks of implementing the new filter bags, the plant reported a 30% reduction in filter bag replacements and a 20% improvement in overall filtration quality. Energy consumption dropped as the system operated more smoothly, leading to significant cost savings. But how did we ensure the perfect fit? It boiled down to three key actions: First, we cross-referenced the equipment manual with the filter bag size chart to confirm compatibility. Second, we conducted on-site measurements to validate theoretical calculations. Third, we piloted the new filter bags in a controlled environment before full-scale deployment. This meticulous approach minimized risks and ensured a seamless transition. Now, let’s talk about another example—a food processing facility dealing with dust collection challenges. Their baghouse dust collector was underperforming due to improperly sized filter bags. Dust particles were escaping, contaminating the workspace and risking compliance violations. Again, the filter bag size chart came to the rescue. By analyzing the collector’s airflow volume, dust load, and cleaning cycle frequency, we pinpointed the ideal filter bag dimensions. The new bags featured a pleated design, increasing surface area for better dust capture while maintaining optimal airflow. The outcome was a cleaner work environment, reduced maintenance downtime, and compliance with health and safety standards. What these cases highlight is the importance of viewing the filter bag size chart not just as a reference tool but as a strategic asset. It’s about matching the physical dimensions of the filter bag to the dynamic demands of your filtration system. And it’s not a one-size-fits-all solution—each application demands a tailored approach. So, how can you replicate this success? Start by gathering detailed information about your equipment: model number, operational hours, peak load conditions, and maintenance history. Then, consult a reputable filter bag size chart that includes real-world case studies or industry-specific guidelines. Don’t hesitate to reach out to manufacturers or filtration experts for personalized recommendations. Remember, the goal is to strike a balance between filtration efficiency, cost-effectiveness, and longevity. By investing time in selecting the right filter bag size, you’re not just buying a product—you’re optimizing an entire process. And in industries where downtime is costly and regulations are strict, that optimization can be the difference between profit and loss.

Case 1: Chemical Processing Plant Transformation

In our first case, a chemical processing plant faced inefficiencies due to undersized filter bags in their HVBF system. The original bags caused excessive pressure drops and clogging, leading to higher energy use and frequent replacements. By using a filter bag size chart specific to HVBF models, we identified larger bags with the right micron rating. After implementation, the plant saw a 30% drop in replacements and a 20% improvement in filtration quality, along with reduced energy costs. The key was cross-referencing equipment specs, on-site validation, and controlled piloting.

Case 2: Food Processing Facility Dust Collection Upgrade

Our second example involves a food processing plant struggling with dust collection in their baghouse collector. Improperly sized filter bags allowed dust to escape, risking contamination and non-compliance. Using a filter bag size chart that considered airflow, dust load, and cleaning cycles, we selected pleated bags with increased surface area. The result? A cleaner workspace, less maintenance, and full compliance with safety standards. This case underscores the need for a tailored approach, matching filter bag dimensions to the system’s dynamic demands.

Armed with the insights from our filter bag size chart guide, you’re now equipped to make informed decisions that enhance your industrial filtration system’s efficiency and save costs. Remember, the right filter bag size isn’t just a detail; it’s the cornerstone of optimal performance. Share this guide with your peers, explore our related resources, and embark on a journey to flawless filtration. The world of industrial filtration is vast—what other challenges will you conquer next?